For more effiecient Biogas production – lignocellulosic biomass depolymerization technology

The organic materials could be decomposed to generate biogas and become the source energy. Since their compositions contain a large amount of methane, they can be used as an energy source for power generation and gas. However, the decomposition of organic matter by microorganisms alone is inefficient in biogas production. The technology of lignocellulosic biomass depolymerization can be applied for biogas production, effectively destroys and decomposes lignocellulosic biomass, and makes it easier for microorganisms to convert them into biogas. However, the efficiency could be increased by 2 to 3 times if the depolymerization is applied. The reaction time could be saved by 50% that can effectively reduce environmental pollution problems and GHG emissions. Through this technology, the bio-refining could play an important role to promote the sustainable development of energy.

The lignocellulosic biomass depolymerization technology combines physical and chemical processes with pre-treated feedstock to obtain some useful substances in the complex structure for following applications. In EU, the application has been advanced from direct mixing of feedstock materials to an implemented stage of depolymerization and decomposition before mixing. It can theoretically improve the methane production and biogas production rate of lignocellulosic biomass.

The enhancement of biogas production while the lignocellulosic biomass has been depolymerized: the potential yield of biogas from depolymerized rice straw, bagasse, and wood chips ranges from 213 to 338 cubic meters of biogas per ton of total solid weight. The efficiency of biogas generation without depolymerization process is very low. However, the yield could be increased by 4-5 times if the pH of the depolymerized biomass is properly adjusted

The effect on biogas production by mixing depolymerized lignocellulosic biomass with swine manure wastewater: wastewater itself can produce about 116 liters of biogas per 30 liters of wastewater for each pig. After adding following depolymerized biomass separately: 3% rice straw, 1% bagasse, 3% wood chips and 1% Pennisetum, the biogas yield achieves 389, 221, 284 and 192 liters for every 30 liters of wastewater, respectively. Compare to the biogas production from the poultry manure wastewater, the yield can be increased by 104%, 64%, 65% and 44% respectively, after mixing with the depolymerized biomass.

The depolymerization technology finds a way out to resolve the problems of waste disposal from agricultural and forestry fields. It can convert waste into energy and chemicals through biorefineries, and introduce resources for recycling and thus ease the pollution caused by those wastes. This technology could enhance the value of the associated industrial chains and get more benefits economically. Looking ahead, we hope we will have the chance to create more biomass energy models with site-specific characteristics.

線上展網址:

https://tievirtual.twtm.com.tw/iframe/c7bb4b95-231c-4eaf-b97a-73d84ae80871?group=3a1a21ad-59dd-4f93-9cbd-9b4a13294f3c&lang=en

Name:Chen, Wen-Hua

Phone:03-471-1400#5115

Address:1000 Wenhua Rd. Jiaan Village, Longtan District, Taoyuan City 325207, Taiwan (ROC)

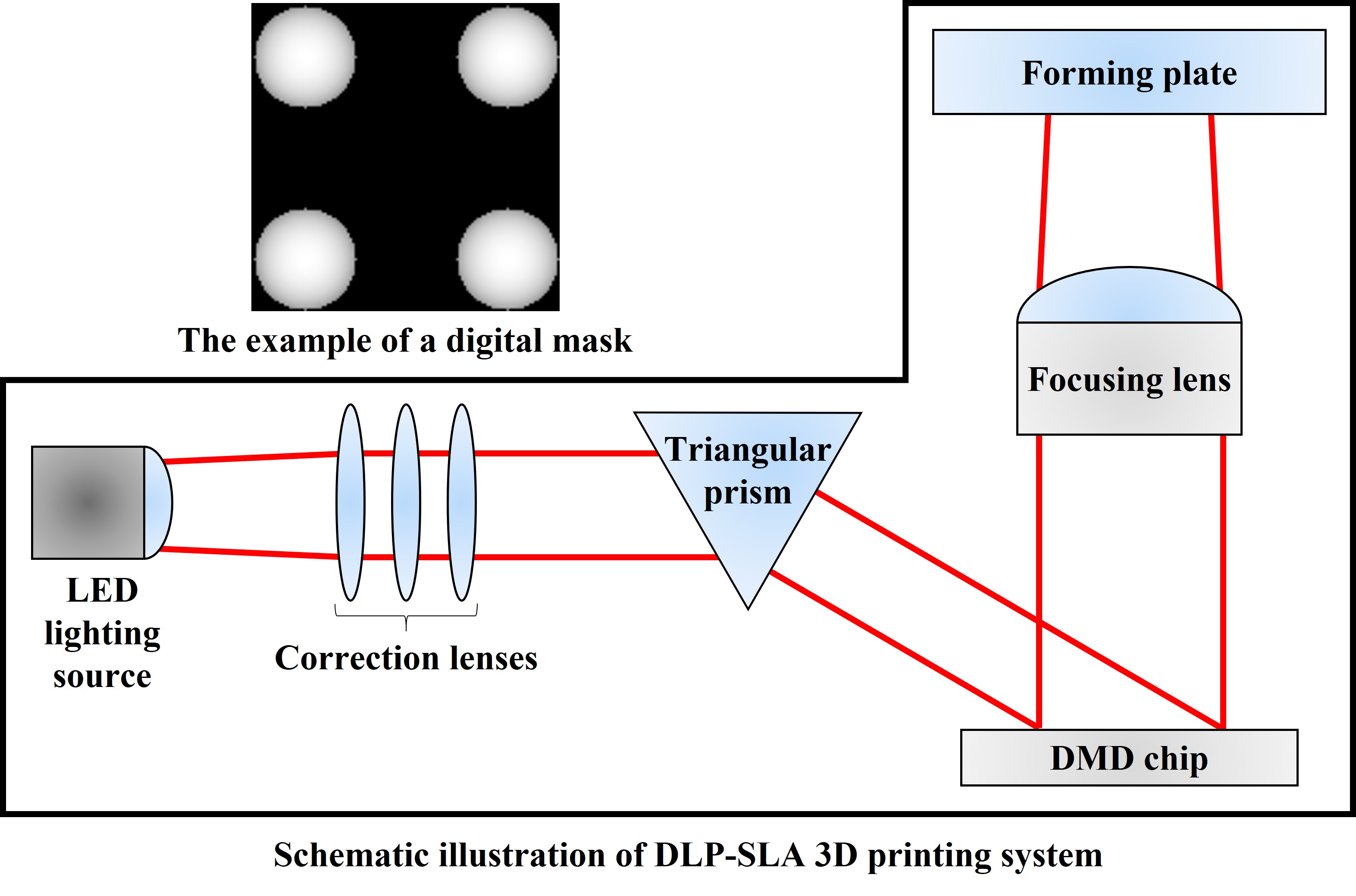

Integrating Digital Grayscale, Defocus Method and Newly Developed Pho topolymer to Stereolithography 3D Printing Process to Rapidly Manufact ure Microlens Array with High Optical Performance

Cellulosic sugar production by ionic solution hydrolysis technology

Integrated Method for Improving Production Rate of Biogas Using Lignocellu-losic Depolymerization with Anaerobic Digestion

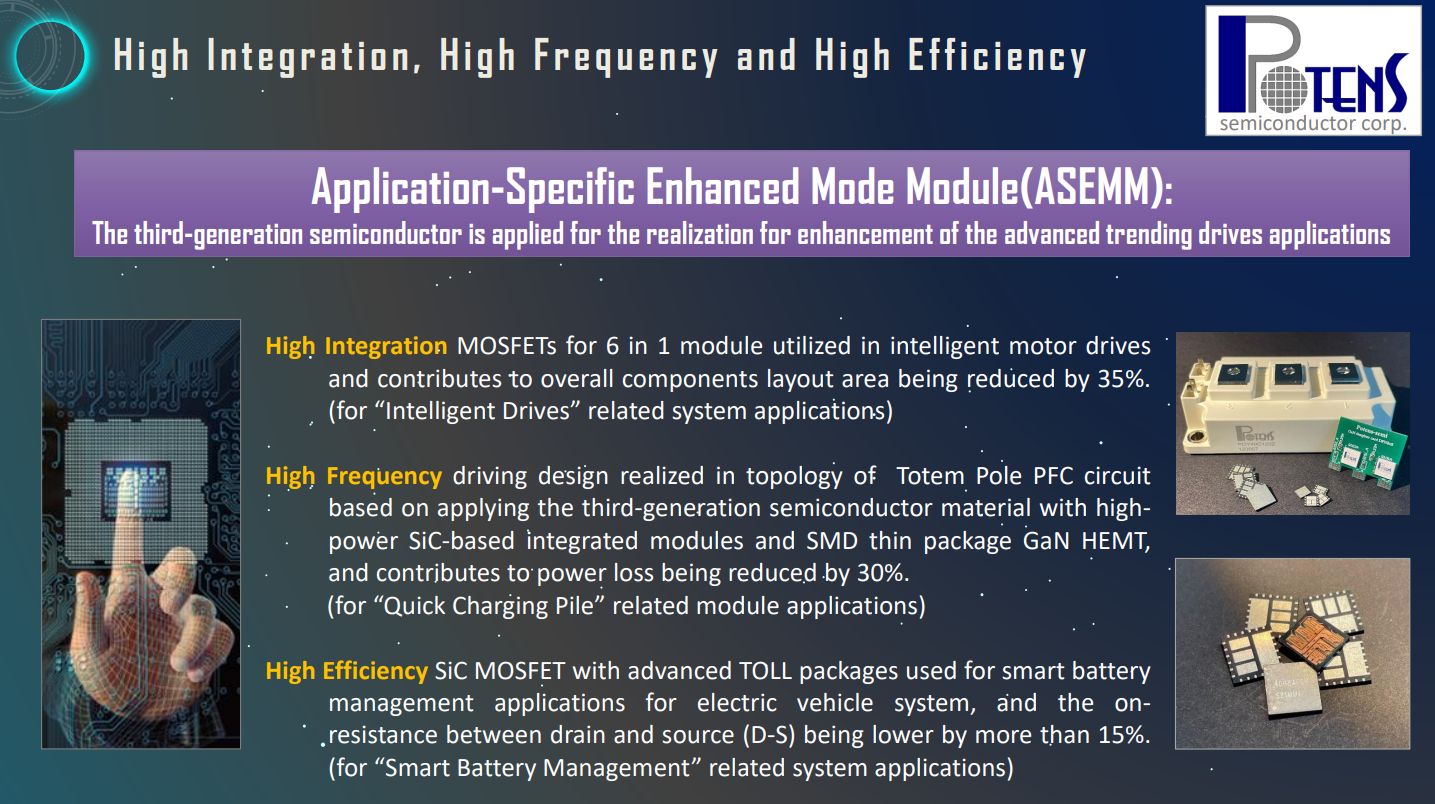

Three-H performance (High integration, High frequency, and High efficiency) power devices including the third-generation semiconductors for the realization of power electronic drives.

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Technical license/cooperation、Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!