Inductively Heated Electrically Conductive Spacers to Enhance Membrane Distillation

Membrane distillation (MD) is a promising low-cost, green (based on utilization of low-quality heat) alternative to dominant water treatment processes like thermal distillation and reverse osmosis (RO). However, it is still not commercially viable, at least in part due to the low flux per unit energy. By employing the use of electrically conductive spacers, it is possible to provided localized heating near the membrane surface with the use of induction heating and without a compromise in flux compared to that of membrane coating. Compared to conventional external feed heating, the temperature distribution across the feed-membrane interface is much more uniform when heating takes place right there. Hence, maximizing the energy efficiency of the heat input which is the main cost in most thermal distillation processes. This savings becomes especially evident when heat loss across the membrane increases as the process is being scaled up.

The potential applications include using such improved MD systems for desalination, tertiary wastewater treatment and pervaporation. Reducing the need for external heating and heat loss associated with external heating, along with the improved energy efficiency allows for the miniaturization of membrane distillation systems, allowing for more portable systems to be deployed as standalone water purification or desalination solutions. Furthermore, the smaller footprint could be easily integrated to processes which produce low temperature waste heat, to supplement heat with high energy efficiency to maintain clean water throughput in the fluctuating waste heat output.

Customer benefits include the improved energy efficiency, reduction of size of membrane distillation system, fast startup and shut down (no lag time involved in heating bulk feed externally) and inherently safe heating method.

The novel use of electrically conductive spacers does not require drastic modifications to current membrane manufacturing processes but instead just replacing the layering of current industrial standard polymeric spacers with electrically conductive ones. Since induction heating uses rapidly changing electromagnetic field from an induction coil and the induction coil can be shaped easily in many ways, the process of integrating induction heating would also be simple and straightforward.

Name:Richard Hung

Phone:

Address:NTU Innovation Centre, 71 Nanyang Drive, #03-01, Singapore 638075

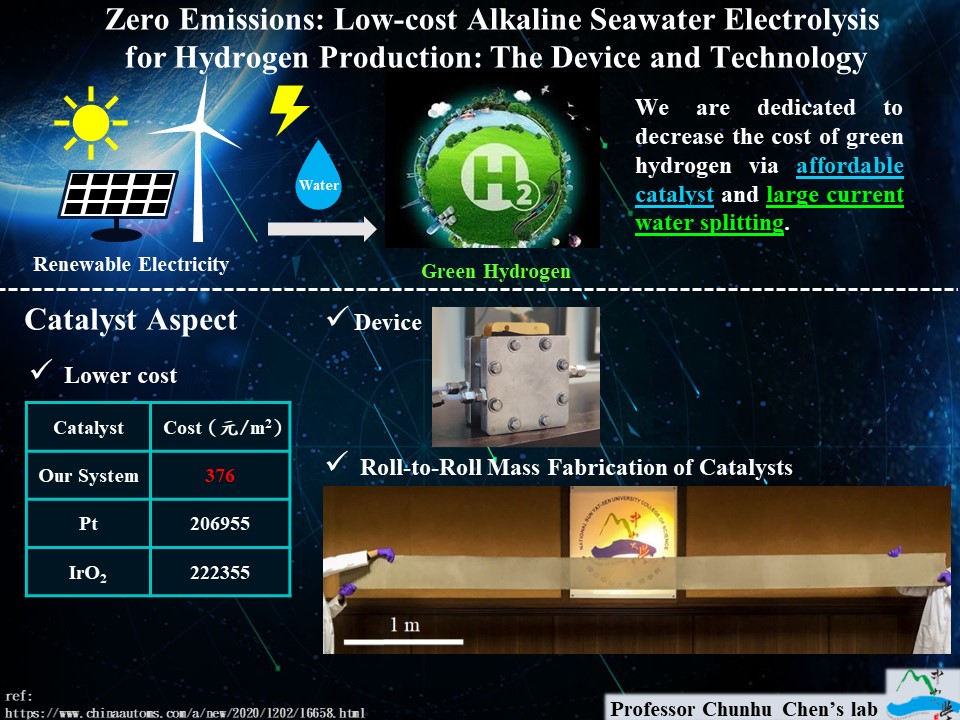

Zero Emissions: Low-cost Alkaline Seawater Electrolysis for Hydrogen Pro duction: The Device and Technology

Integrated Technology of Recycling Waste Paper Containers to Produce Marine Degradable Plastics

A process for fabrication of a fully dense electrolyte layer embedded in membrane electrode assembly of solid oxide fuel cell

Sustainable development of CO2: CO2 chemically converted to magnetic carbon nanofibers and their environment and biomedical applications

Technology maturity:Experiment stage

Exhibiting purpose:Technology transactions

Trading preferences:Exclusive license/assignment、Negotiate by self、Technical license/cooperation

Coming soon!