Mass production technology of fluorinated graphene and its multi-functional applications on surface coating

"In this invention,FG is obtained by the fluorination of electrochemically exfoliated graphene (F-ECG), which is found to be a ONE-STEP approach for the scalable preparation of FG. The precursor with fluorine atoms is mixed with the ECG followed by the apply energy to form the fluorinated graphene. This process demonstrates an eco-friendly and safe as well as scalable features. We have demonstrate that the FG flakes as a filler in epoxy(FG/epoxy nanocomposite) can achieve the highest reported anticorrosion performance (corrosion rate (CR) = 7.83x10-8 mm/year; current = 3.37 x10-12 A cm-2).In our invention, FG is obtained by ONE-STEP approach for the scalable preparation of FG. FG can achieve the three factors, including the excellent dispersibility, super-hydrophobicity, and high electrical insulator, which was beneficial for impeding the entry of molecules through the coating to the coating-substrate interface and attenuating electron transport in the interconnected graphene network

(1)A unique, facile and ecofriendly method to obtain FG is first reported,

(2) Only 1 wt.% FG loading achieve the leading value among the reported anticorrosion performances of other materials (corrosion rate (CR) = 7.8310-8 mm/year; current = 3.37 10-12 A cm-2).

(3)Diffusion coefficient (Dacs) is at least 2 orders of magnitude lower than that reported gaphene.Mass-produced fluorination process is safe and the process is simple, efficient, high yield, and low cost.

1. This technology can adjust the hydrophobicity of fluorinated graphene according to industrial needs

2. Additives that can be applied to polymer materials to improve the effectiveness of anti-corrosion coatings, can be applied to offshore wind power tower column anti-corrosion, etc.

3. Can be coated on circuit boards as an anticorrosion passivation layer for high-level circuit boardnor military-grade electrical components.

4. The surface of the fluorinated graphene is negatively charged. The electroplating method can be used to form a fluorinated graphene film on the surface of metal components, especially for irregularly shape."

National Central University is a public research university with long-standing traditions of the Republic of China based in Taiwan. It was founded in 1902 and renamed in 1915. The school was initially located in Miaoli when it first moved to Taiwan, but relocated to Zhongli in 1962 and developed into a comprehensive university. It's the first university in Taiwan to research industrial economics,[3] and economic development (Taiwan's Consumer Confidence Index is released monthly by NCU).[4] NCU is a member of AACSB.[5] NCU is one of the six national universities in research selected by the Ministry of Education.

Name:蘇清源

Phone:03-422-7151#34911

Address:No. 300, Zhongda Rd., Zhongli District, Taoyuan City

Cellulose nanofiber film for oil-repellent and anti-fingerprint applications without fluorinated compounds

The new material and application technology of weather-resistant and anti-corrosion solar photovoltaics frame in coastal field

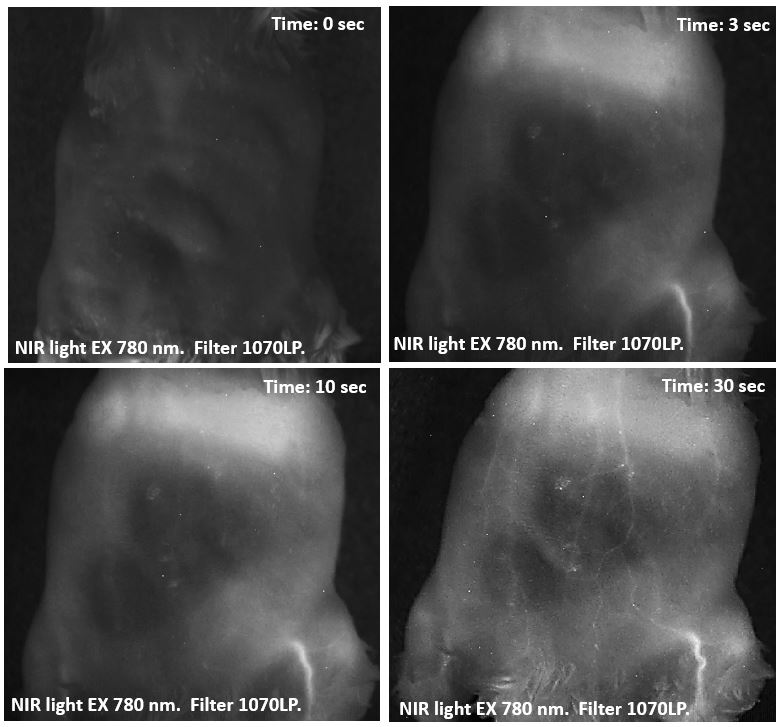

High-brightness fluorescent gold nanoclusters infrared imaging agent technology with clinical application potential

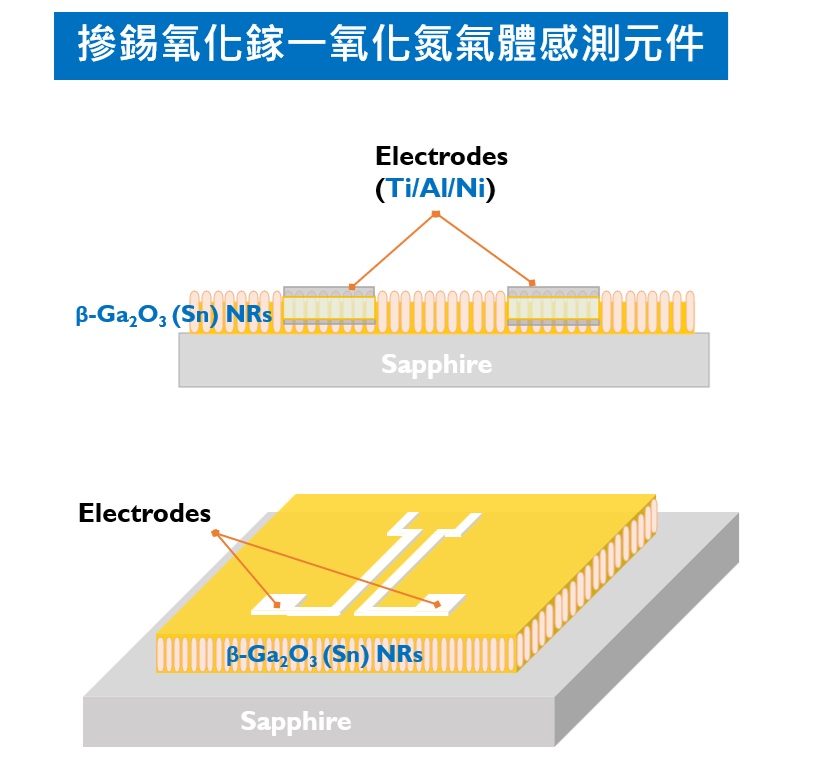

A novel high-performance Sn-doped gallium oxide thin-film nitric oxide gas sensor for applications in smart healthcare and environmental monitoring

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation、Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!