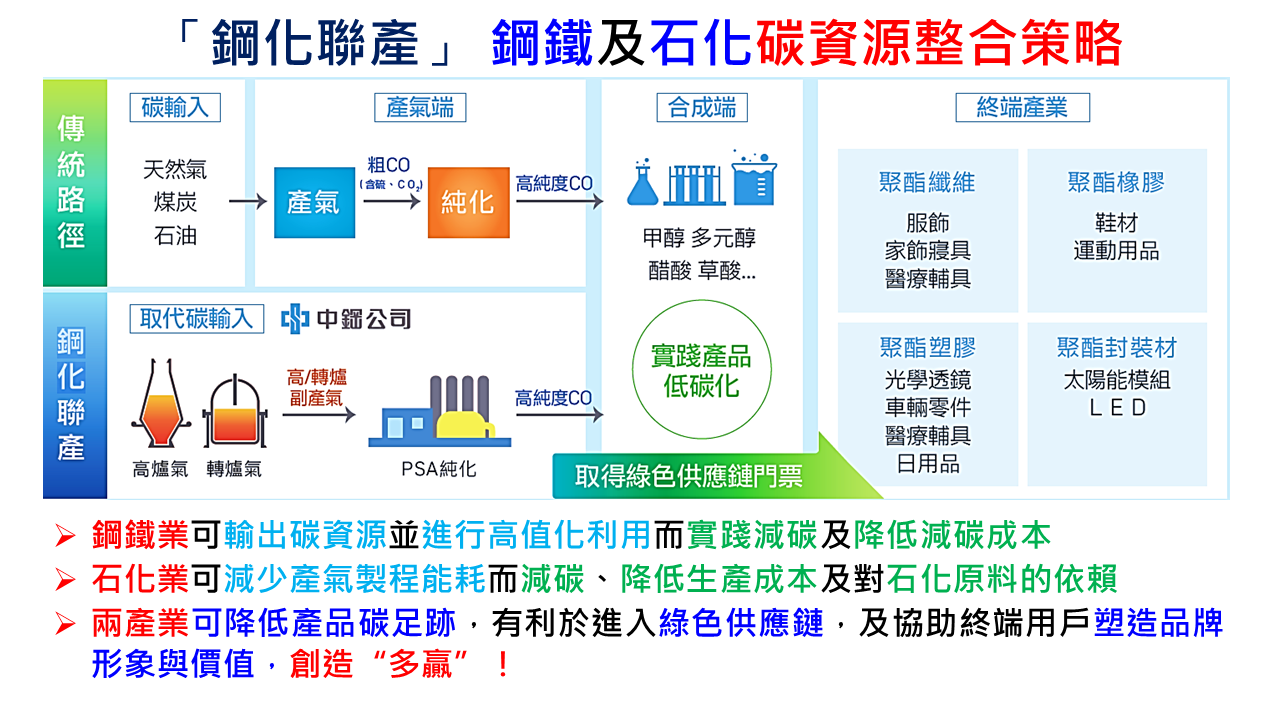

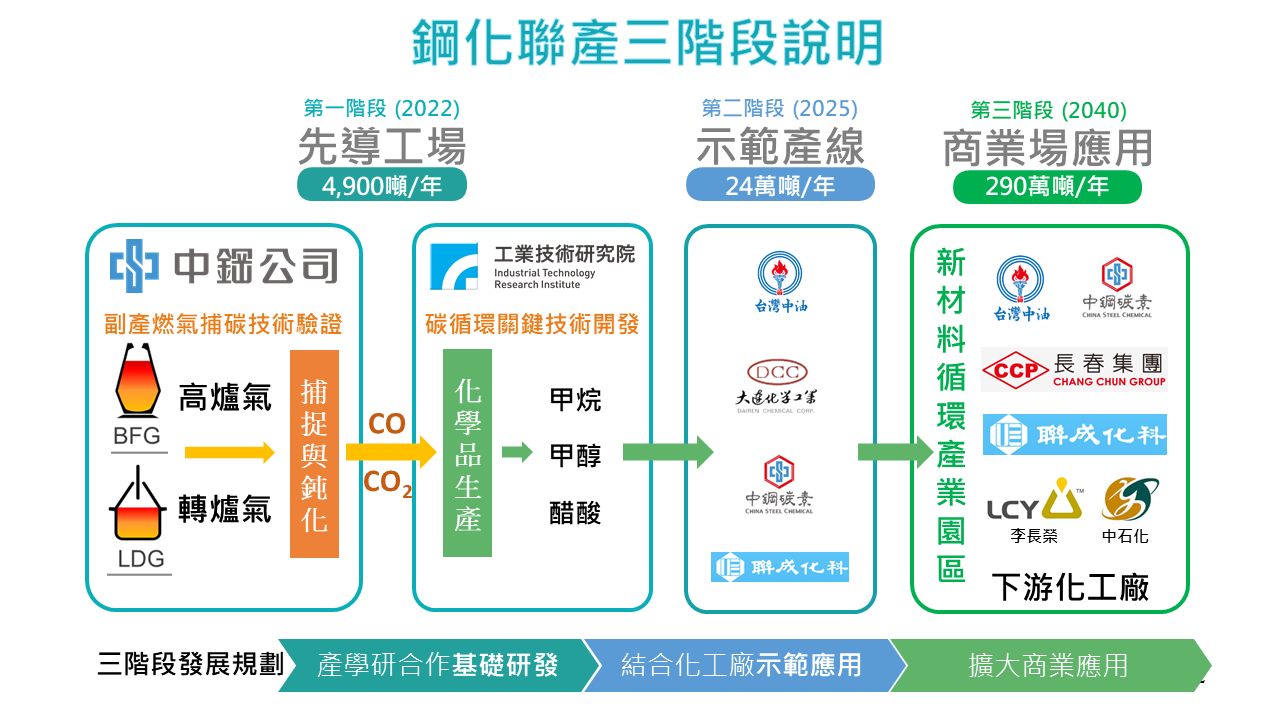

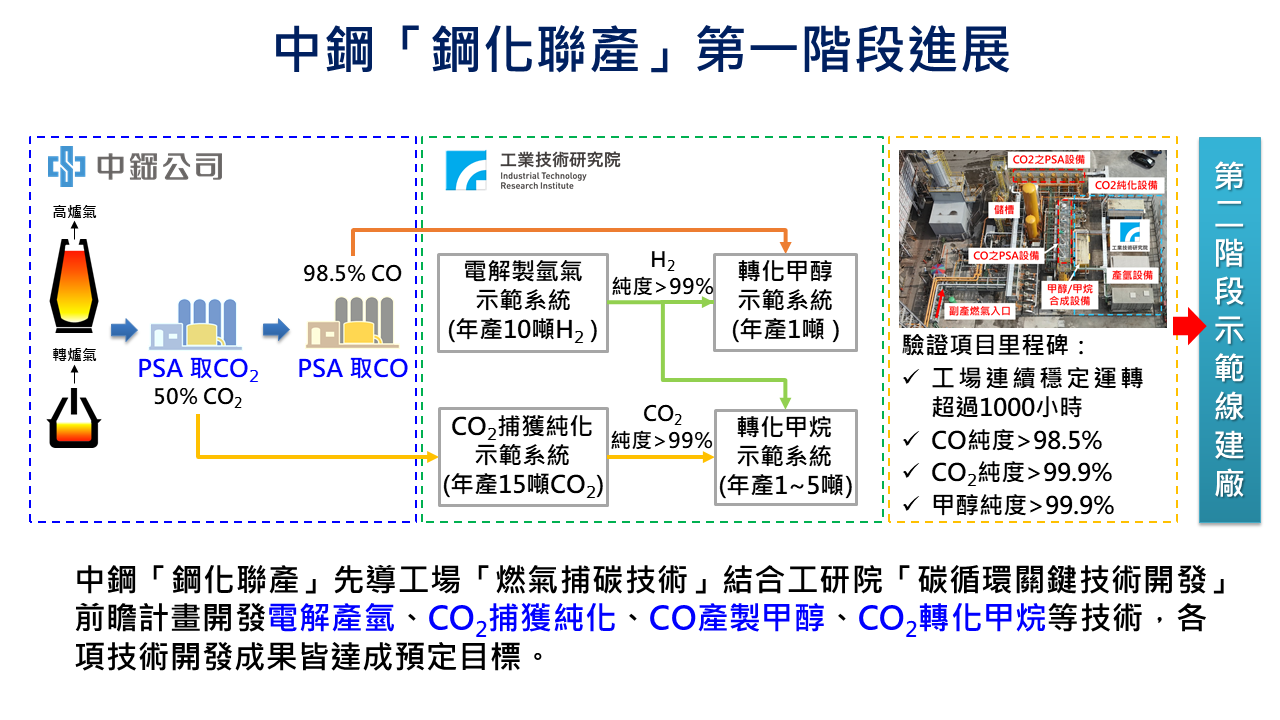

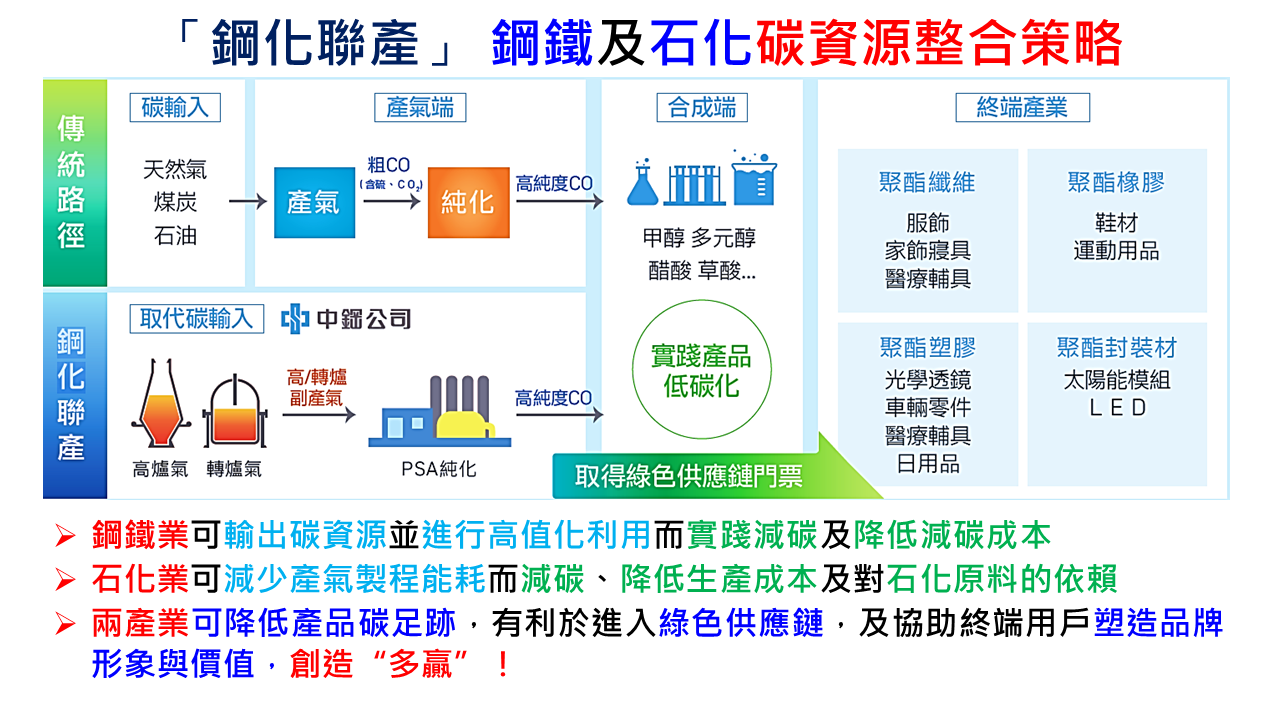

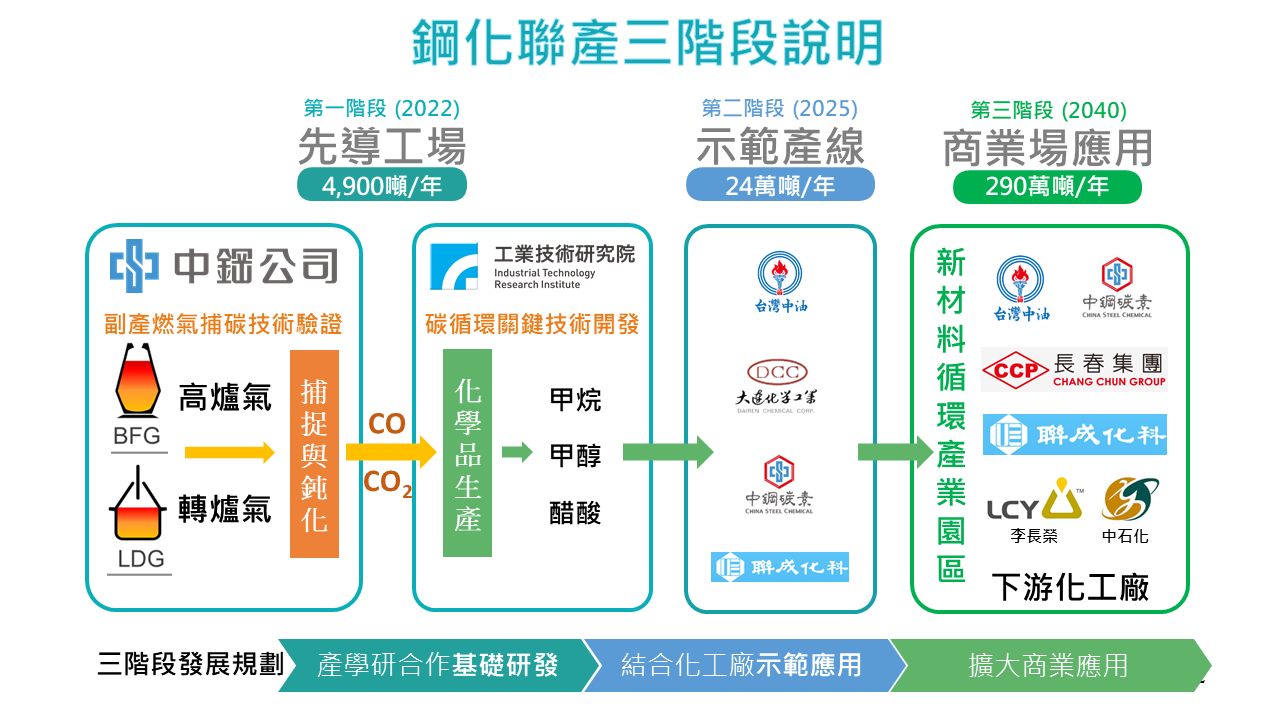

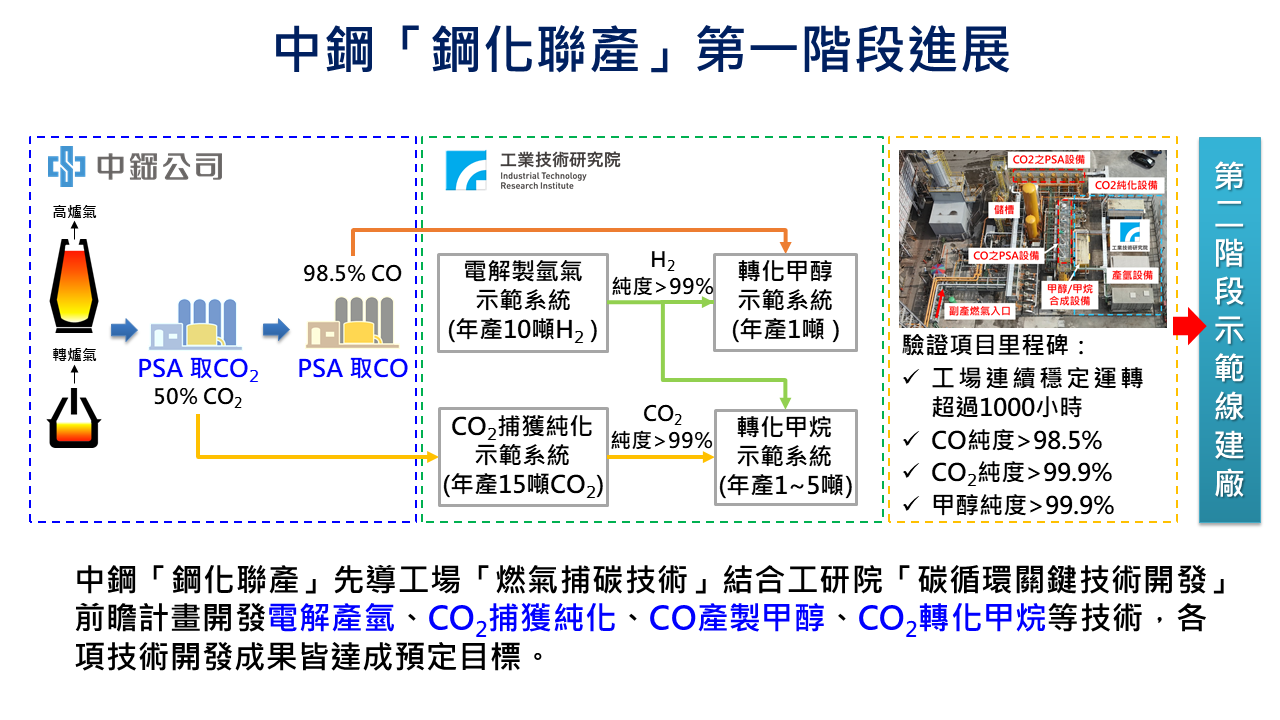

The “Coproduction between Steel and Petrochemical Plants” initiative launched by CSC and the petrochemical industry is divided into three stages. In Stage 1 - “Establishing laboratory and pilot plant technology,” carbon capture from by-product gases and high-value technologies are developed in collaboration with the Industrial Technology Research Institute (ITRI) and funded by the National Forward-looking Program, with site validation to be conducted as well. In Stage 2 - “Building a demonstration production line for coproduction between steel and petrochemical plants,” the first demonstration production line for coproduction between steel and petrochemical plants in Taiwan will be built, with the facility projected to reduce 240,000 tonnes in carbon emissions each year. Moreover, Stage 3 involves extending the initiative to “commercial use,” where it is projected to reduce 2.9 million tonnes in carbon emissions each year, thereby helping the petrochemical industry form a low-carbon chemical industry chain.CSC and CPC Corporation signed a memorandum of understanding on August 27, 2021, with the construction of an R&D platform as the prelude to the initiation of cooperation. CSC is also in talks with other petrochemical companies such as Chang Chun Group, Dairen Chemical Corporation, CSCC, and UPC Technology Corporation over potential cooperation. CSC looks forward to seizing new business opportunities from carbon reduction through collaboration and progressing towards net zero carbon emissions together, thereby “contributing to environmental protection while generating benefits simultaneously” and turning the carbon reduction crisis into a turning point and a business opportunity. The pilot plant for co-production between steel and petrochemical plants was completed in September 2022. CSC collaborated with ITRI in conducting on-site verification of by-product gas carbon capture and high value technologies.

China Steel Corporation (CSC), located in Kaohsiung City, was founded in December 1971. With annual crude steel production of 10 million metric tonnes, CSC’s main products include plates, bars, wire rods, hot and cold rolled coils, electrogalvanized coils, electrical steel coils, and hot-dip galvanized coils. The domestic market takes roughly 58.9% of CSC’s production and the exports take the remaining 41.1%. CSC is the largest steel company in Taiwan with market share of more than 50% and export products mainly to Southeast Asia, Europe and Japan.

Name:

Phone:0912162024

Address:1, Chung Kang Rd., Hsiao Kang, Kaohsiung 81233, Taiwan, Republic of China

The Technology of Optimal Proportion Allocation between Renewable Energy and Energy Storage System for Microgrid.

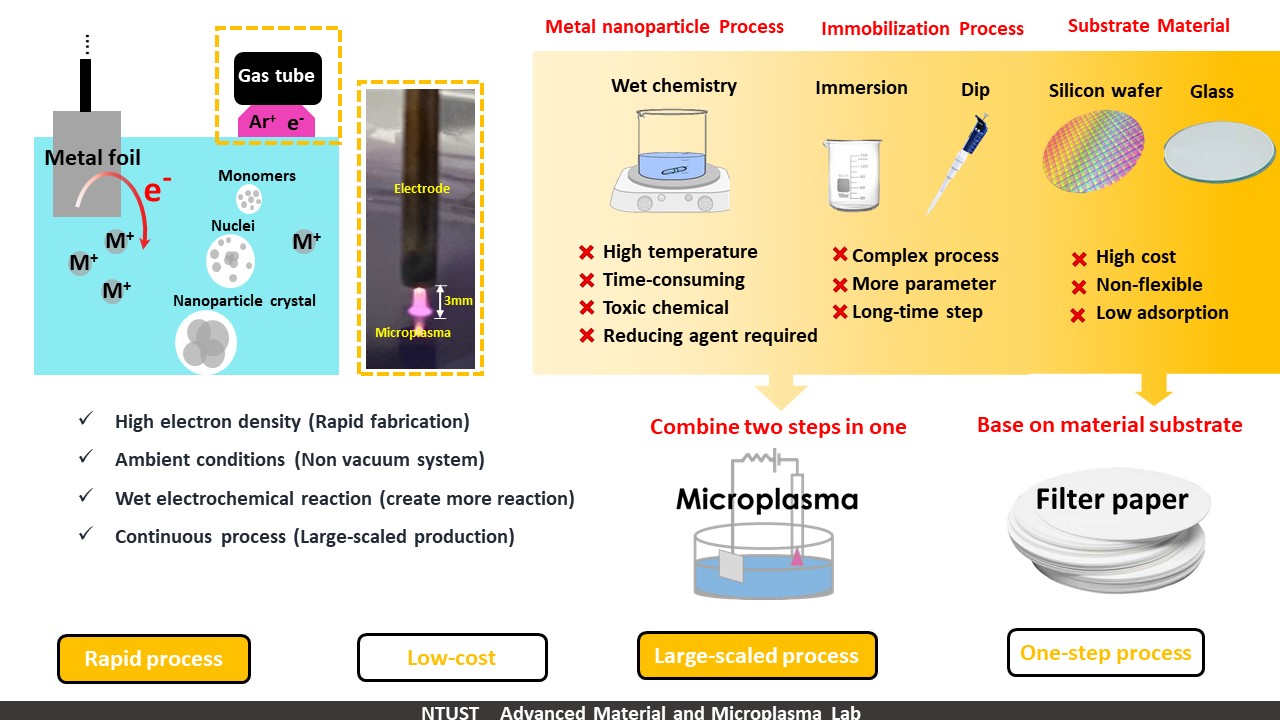

Three dimension nanoporous nanomaterial Microplasma-Enginnered assemblies on paper substrate for hydrogen gas production , surface-enhanced Raman scattering and catalytic reduction

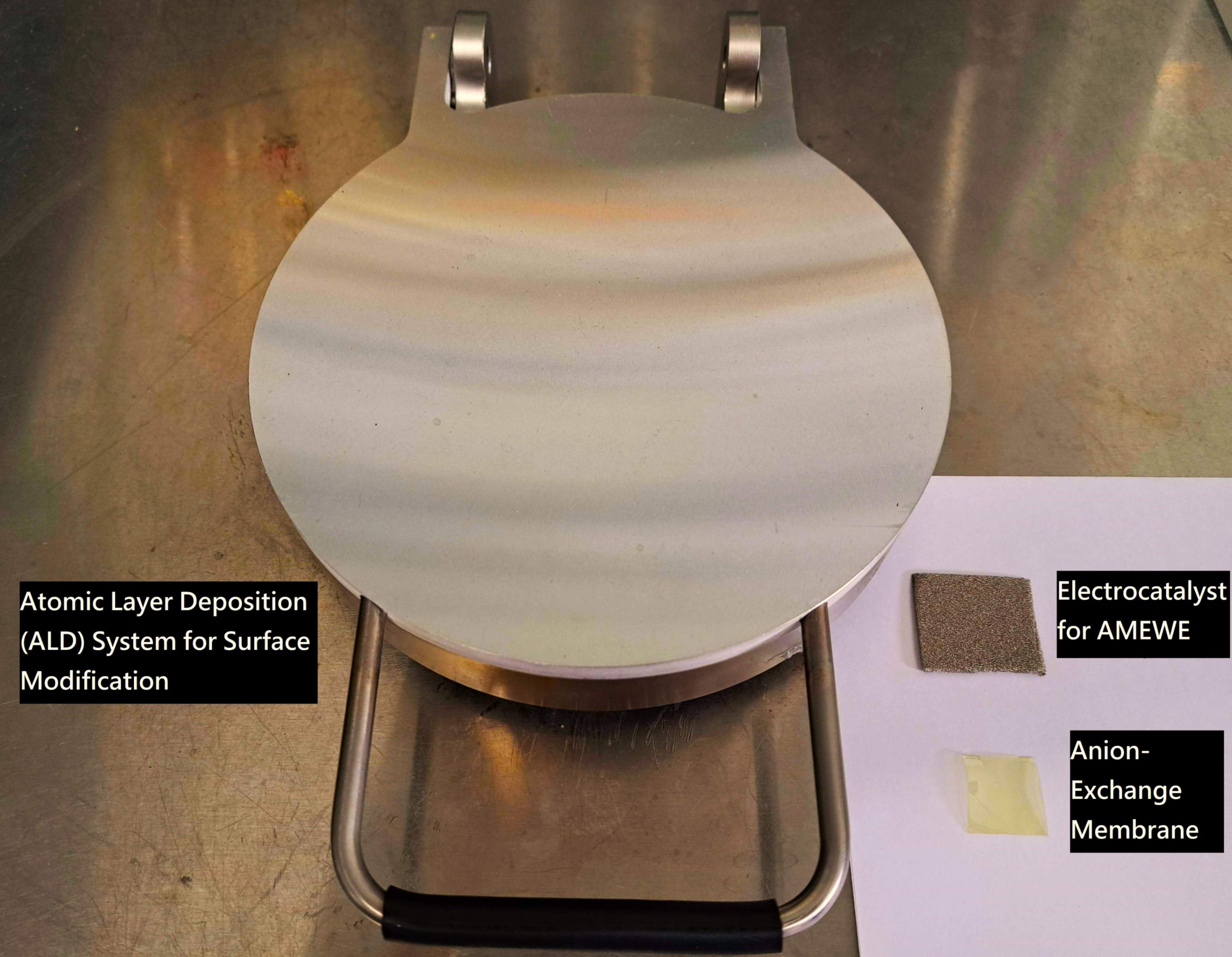

High practicality surface modification technology for enhancing hydrogen production via water electrolysis and solid-state hydrogen storage efficiency

Upcycled Waste PET-Based Technologies for Conductive Self-Healing Wearables, Dynamic Environmental Monitoring, and Photochromic Anti-Counterfeiting

Technology maturity:Trial production

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!