High performance proton exchange membrane fuel cell based on laser processed alloy catalyst technique and metal foam flow field bipolar plate with built-in water-cooling design

To enhance the performance and reduce the cost of proton exchange membrane fuel cell, we developed a novel laser-based technique for alloy catalyst and a metal foam (MF) flow field bipolar plate (BP) with built-in water-cooling. We used pulsed laser deposition and scanning CW laser process for synthesizing Pt-skinned alloy catalysts. The technique significantly reduces the Pt loading with improved performance. The MF flow field BP with built-in water-cooling design differs from the traditional parallel channel or the serpentine flow channel. This innovative design promotes both efficient gas transfer and electronic conduction at the same time. The combination of MF and inlaid water cooling area can effectively increase the power density of the fuel cell stack.Compared with the conventional process, using the laser-based processes, we can reduce the Pt loading to 20 % for the same power output. After 5000 cycles of accelerated test, the PLD synthesized catalyst maintained 60% of the activity, while the traditional catalyst retained only 7%.

Laser heat treatment is also used to produce Pt-skinned alloy catalysts to reduce the amount of Pt further. The Pt specific power density reached 12 kW/gPt, passing the US DOE's 2020 target of 8 kW/gPt.

The use of metal foam increases performance by more than 20%. Coated with graphene, the corrosion current density is 0.65 μA/cm2, passing the US DOE's 2020 anti-corrosion target of 1 μA/cm2.

With the embedded water cooling design, we can reduce 9% stack volume and save 12% processing cost for a 2 kW stack.We applied pulsed laser deposition to deposit nanoparticles as the catalyst on the gas diffusion layer electrode successfully. Also, the continuous-wave laser post-processing is employed for laser heat treating the electrode surface, and the alloy electrode nanostructure is successfully modified to improve the catalyst activity and durability. A laser is an indispensable tool for smart manufacturing in the future. In addition to the synthesis of catalyst electrode materials, the application of laser in fuel cells can also include bipolar plate cutting, flow channel carving, welding between electrode plates, flow channel surface modification.

Name:林晉賢

Phone:03-4267348#37327

Address:No. 300, Zhongda Rd., Zhongli District, Taoyuan City

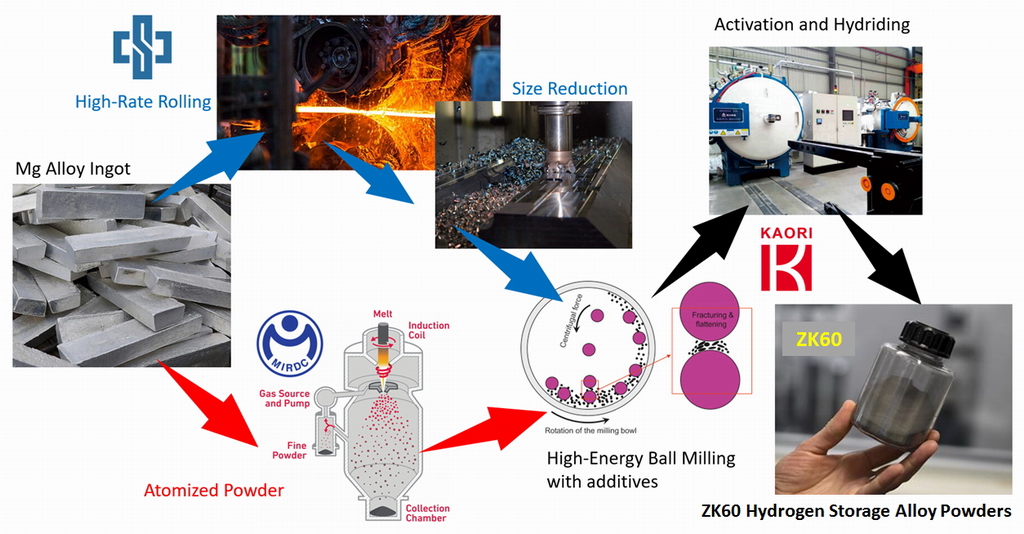

High-performance solid-state hydrogen storage alloy and portable temperature-controlled storage cylinder

Method for manufacturing an active substance for inducing self-lysis in microalgae cells, active substance obtained therefrom, and method for inducing self-lysis in microalgae cells

Method for manufacturing an active substance for inducing self-lysis in microalgae cells, active substance obtained therefrom, and method for inducing self-lysis in microalgae cells

CORMETECH High Efficiency Catalysts for Nitrogen Oxide (NOx) and Carbon Monoxide (CO) control in gas fired power plant applications.

Technology maturity:Prototype

Exhibiting purpose:Technology transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation、Negotiate by self

Coming soon!