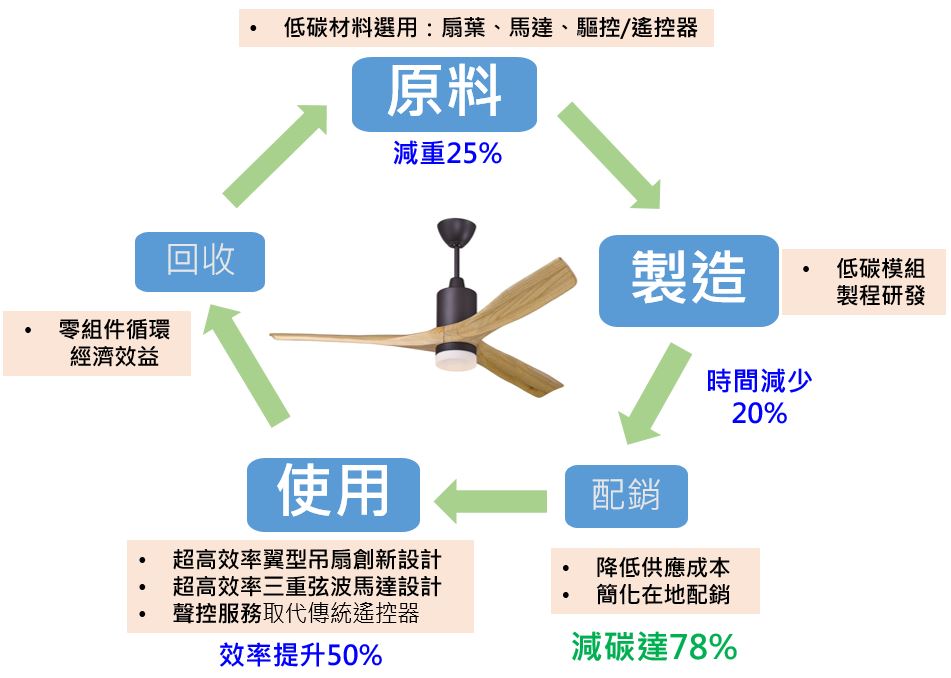

• Ultra-efficient airfoil blades and a high-efficiency outer-rotor permanent magnet brushless motor drive module without rare earth elements create a low-carbon emission ceiling fan. This fan boasts super-quiet operation, low vibration noise, calibration-free setup, easy assembly, a wide speed range, and high lifespan reliability, positioning it at the forefront of global performance.

• Incorporating low-carbon innovation design throughout the five stages of the product lifecycle: (1) Raw Material Stage – utilizing recyclable low-carbon materials; (2) Manufacturing Stage – implementing low-cost shared mold automated processes; (3) Distribution Stage – reducing supply costs and simplifying local distribution; (4) Usage Stage – introducing ultra-high aerodynamic efficiency airfoil blades, efficient motors, and voice-controlled services to replace traditional remotes; (5) Recycling Stage – promoting the cyclical use of ceiling fan components.

ITRI is a world-leading applied technology research institute with more than 6,000 outstanding employees. Its mission is to drive industrial development, create economic value, and enhance social well-being through technology R&D. Founded in 1973, it pioneered in IC development and started to nurture new tech ventures and deliver its R&D results to industries. ITRI has set up and incubated companies such as TSMC, UMC, Taiwan Mask Corp., Epistar Corp., Mirle Automation Corp., and Taiwan Biomaterial Co.

Name:

Phone:03-5916357

Address:195, Sec. 4, Chung Hsing Rd., Chutung, Hsinchu, Taiwan 31040, R.O.C.

Industry 3.5 Solution for Smart Energy Saving and Chiller Operation Optimization

Sustainable development of CO2: CO2 chemically converted to magnetic carbon nanofibers and their environment and biomedical applications

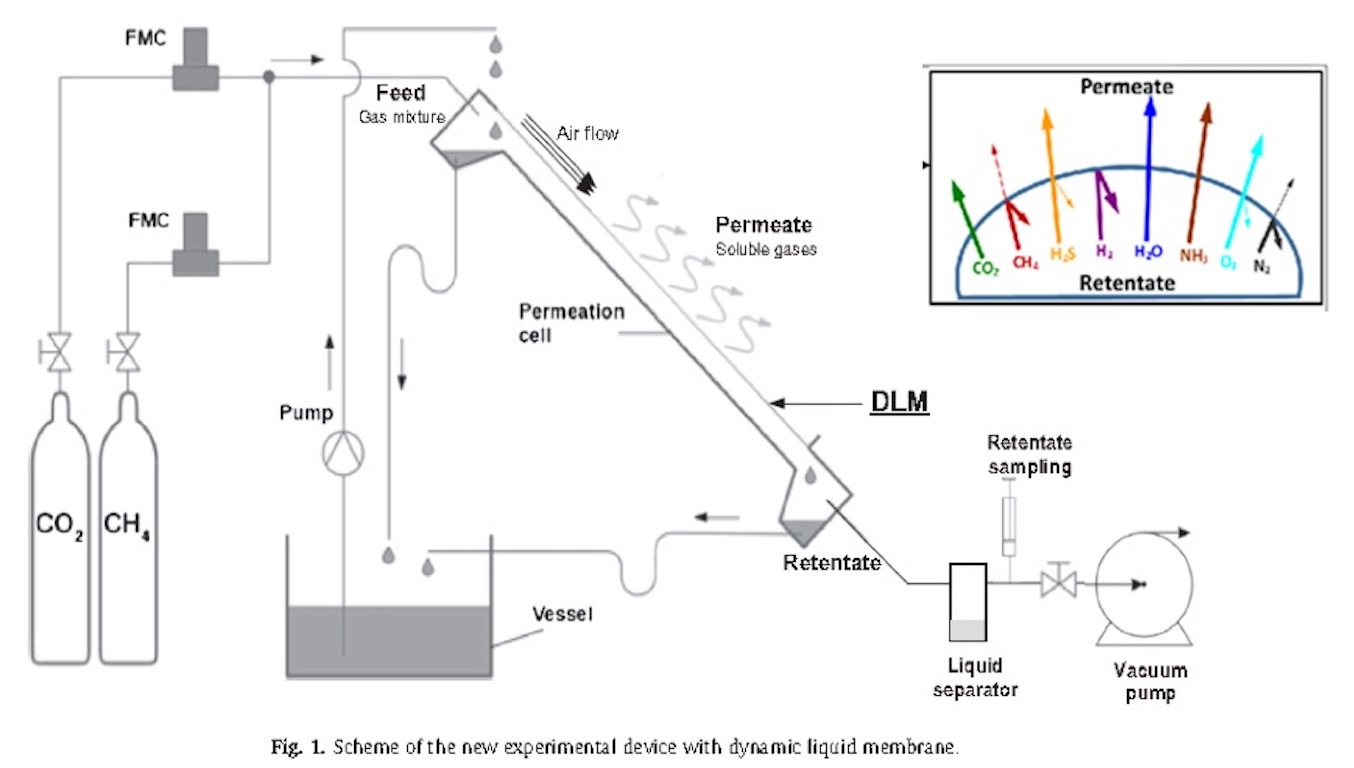

Innovative water-based dynamic bubble membrane generation device for CO2 separation and capture

Innovative Low-carbon Energy-saving Ceiling Fan

Technology maturity:Prototype

Exhibiting purpose:Technology transactions

Trading preferences:Negotiate by self

Coming soon!