High efficiency External Rotor BLDC Motor technology and automated demonstration production line

1.Brushless DC External-Rotor Motor has a larger rotor radius, higher torque under low speed, higher efficiency and more stable operation. Moreover, since the stator is outside the rotor, the winding process is simpler, the slot filling factor can be upgraded, and the pole/slot design can be more flexible for mass production, while both the cogging torque and torque ripple can be reduced.

2.The pilot-run line with automatic assembly technology has been built-up at Shalun of Tainan, it comprises stator winding, rotor magnet sticking, product assembly & performance testing. The annual production capacity can reach to 50,000 sets.

3.The developed product has been demonstrated sales of more than 15,000 sets in ceiling fan market of Europe, Australia, Southeast Asia and Taiwan.

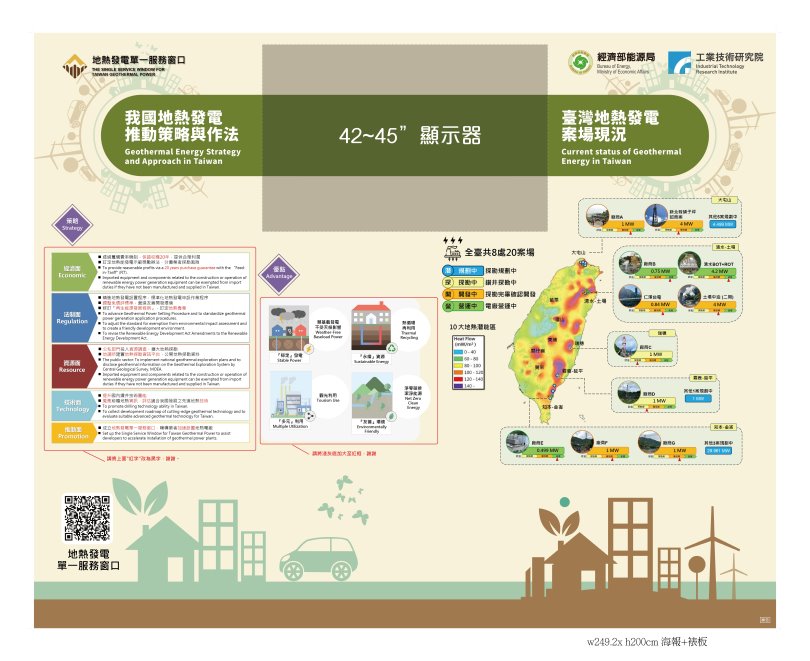

Responsibilities include the formulation of energy policies and regulations; forecasting, planning, and promoting energy supply and demand; reviewing matters related to energy development, production, storage, conversion, distribution, sales, and utilization; proposing energy tariff schemes and reviewing pricing mechanisms; granting permits, registration, management, guidance, and supervision of energy-related enterprises; registration and oversight of certified energy professionals; establishment and management of energy data systems; promotion of energy conservation measures, technical services, and public awareness initiatives; research, development, and dissemination of new energy, renewable energy, and energy-saving technologies; coordination and cooperation in international energy affairs; and other matters related to energy administration.

Taiwan Geothermal Power Generation Promotion Strategy and Approaches & Current Status of Geothermal Power Generation Projects in Taiwan

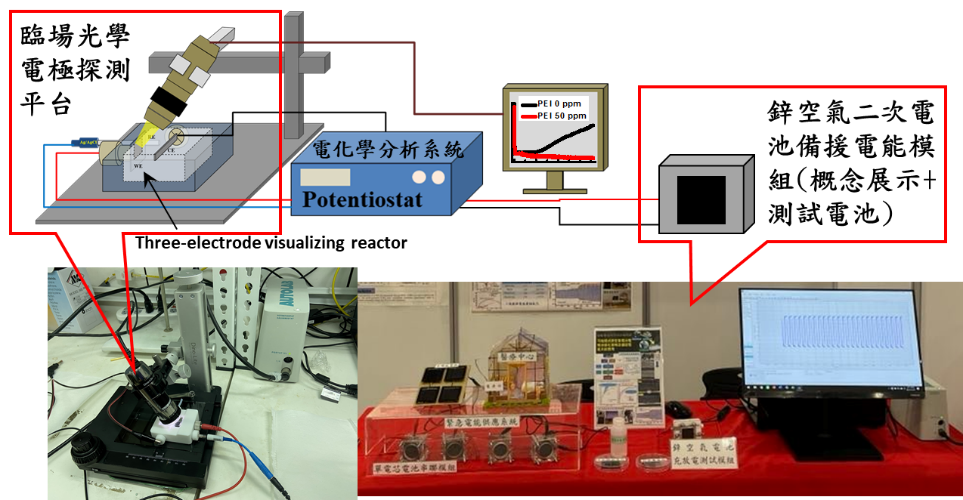

Portable in situ/operando optical microscopy technology for electrode reactions detection and applied in developing advanced high-performance zinc secondary batteries

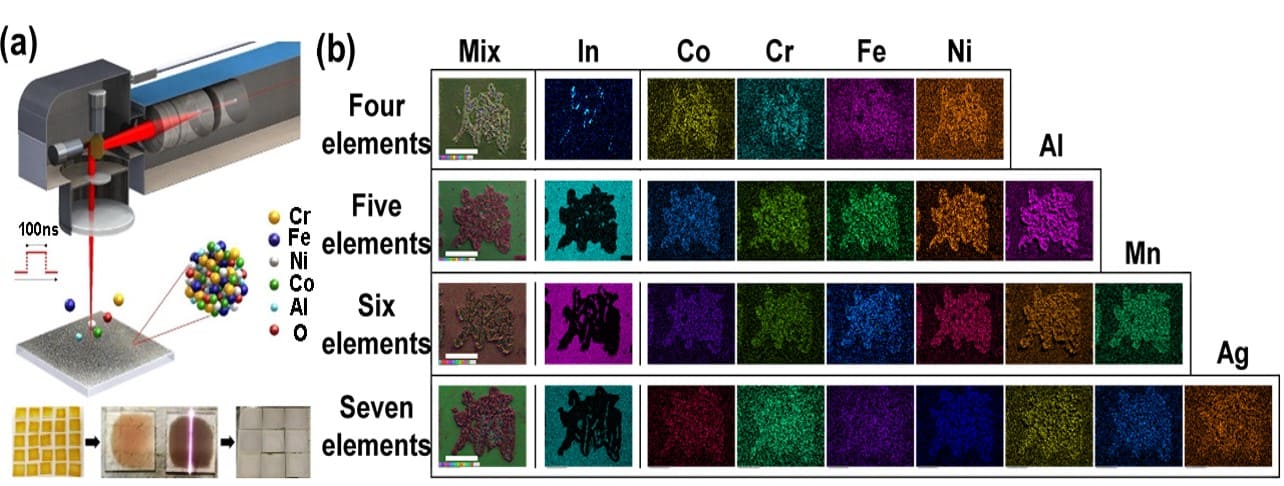

Advanced high-entropy nanomaterial fabrication technology for hydrogen production from seawater splitting

CORMETECH High Efficiency Catalysts for Nitrogen Oxide (NOx) and Carbon Monoxide (CO) control in gas fired power plant applications.

Technology maturity:Trial production

Exhibiting purpose:Technology transactions

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!