The development of water-vapor barrier films for the third-generation photovoltaic cells

The organic layer and organic-inorganic multi-layers deposited on the packaging substrate to achieve the ultra-high water barrier performance, lower than 10e-5 (g/m2/day). This technology can apply to all flexable electronic devices. The fabrication in this team evolved from batch-to-batch process in the 1st year to tray-to-tray process in the 3rd year. The roll-to-roll wet process and in-line dry process are constructed in the 5th year and ready for commercialization.

The WVTR of an uncoated plastic film is greater than 2 (g/m2/day). Depositing an inorganic coating on it, its WVTR reduces to 1~10e-1(g/m2/day). The semiconductor devices require the film of WVTR between 10e-2~10e-3(g/m2/day). To achieve the WVTR, hybrid organic and inorganic layers must be coated on the substrate. Taiwan currently has no products lower than 10e-3 (g/m2/day). The barrier film of this team using hybrid multi-layer stacking makes WVTR lower than 10e-5 (g/m2/day), which is not only sufficient for photovoltaic devices but also contributes to the OLED market in the future.

The WVTR for food packaging is between 1~10e-2(g/m2/day). Inorganic electronic products, such as light-emitting diodes, solar cells, requires WVTR around 10e-2~10e-3 (g/m2/day). The WVTR for organic electronic devices needs to be less than 10e -3(g/m2/day). OLED has the most critical one which must be lower than 10e-5 (g/m2/day). According to the UK IDTechEx forecast, from 2019 to 2029, the market value of In-Line thin-film packaging will rise from 200 million USD to 600 million USD, of which the largest demand is for OLED-related products.

線上展網址:

https://tievirtual.twtm.com.tw/iframe/d668f9b6-6898-448f-b1de-cb7864f2bc10?group=23bfb1fa-dd5b-4836-81a1-4a1809b1bae5&lang=en

The innovative technology that turns waste into treasure – Silicon Dioxide regenerated from semiconductor waste that contains Silicon

Sustainable development of CO2: chemically converted to magnetic carbon nanofibers and their industrial applications

The new material and application technology of weather-resistant and anti-corrosion solar photovoltaics frame in coastal field

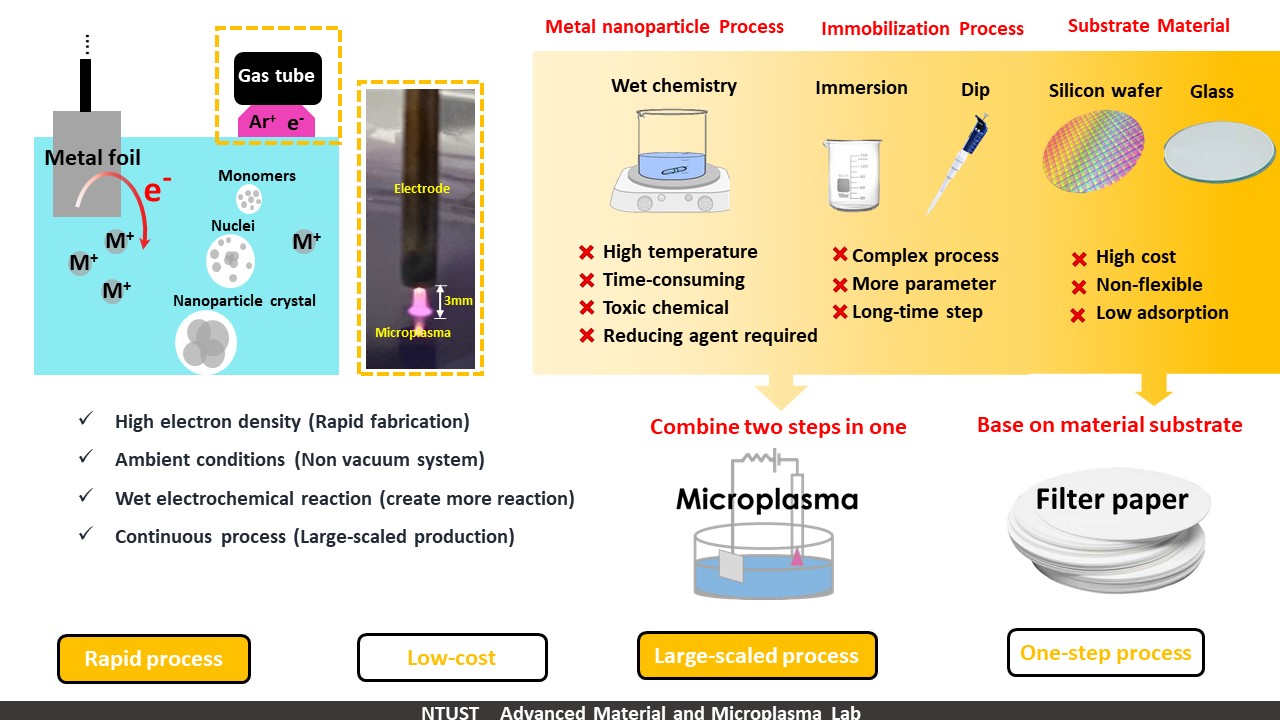

Three dimension nanoporous nanomaterial Microplasma-Enginnered assemblies on paper substrate for hydrogen gas production , surface-enhanced Raman scattering and catalytic reduction

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions

Trading preferences:Exclusive license/assignment、Technical license/cooperation、Negotiate by self

Coming soon!