Achieving economic recycling applications is the goal of waste plastic recovery technology. This technology addresses the specific requirements of polyol in the flexible PU foam process. It has developed a method to control the hydroxyl value of polyols resulting from polyurethane degradation. By breaking down some of the urethane functional groups in the PU network structure, the molecular weight and hydroxyl values are adjusted to a range suitable for flexible foam. This achieves a quality specification similar to that of new petrochemical polyols. The technology has been successfully applied to recycled regenerated foam, achieving the goal of a waste-free production process.

ITRI is a world-leading applied technology research institute with more than 6,000 outstanding employees. Its mission is to drive industrial development, create economic value, and enhance social well-being through technology R&D. Founded in 1973, it pioneered in IC development and started to nurture new tech ventures and deliver its R&D results to industries. ITRI has set up and incubated companies such as TSMC, UMC, Taiwan Mask Corp., Epistar Corp., Mirle Automation Corp., and Taiwan Biomaterial Co.

Chemical Recycling Technology of Waste Polyester Textiles

.png)

Mono-material is crucial for recycling:TPEE Adhesive Hot Melt Technology.

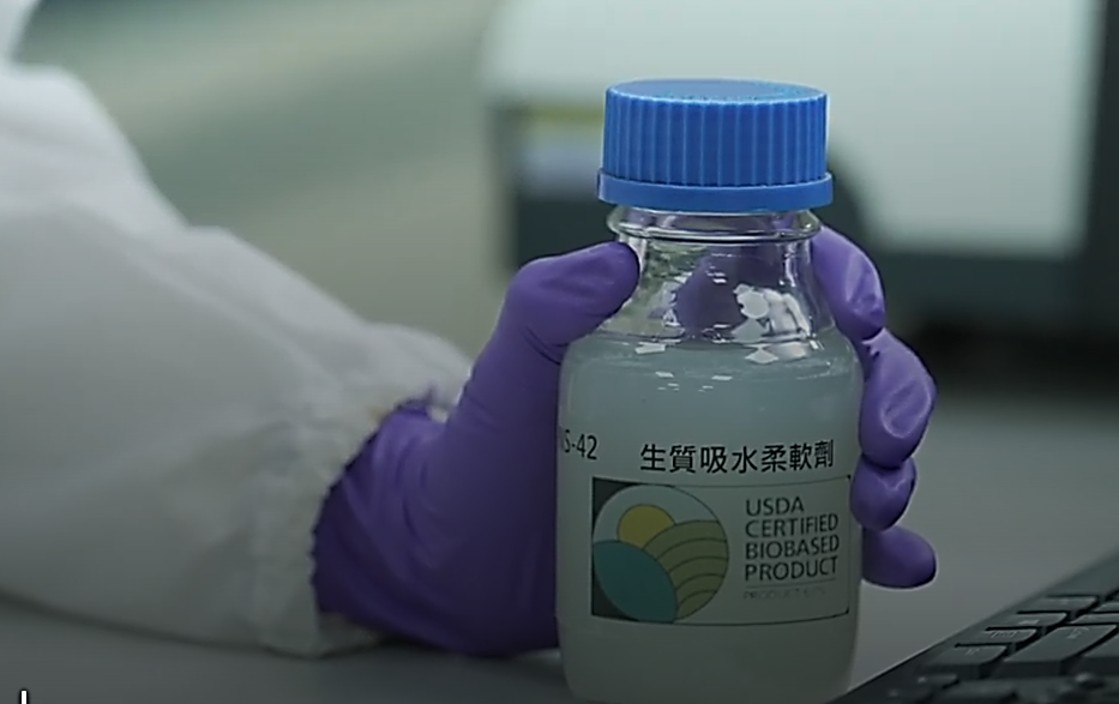

Bio-based Chemicals with Softening- wicking- elasticity Technology

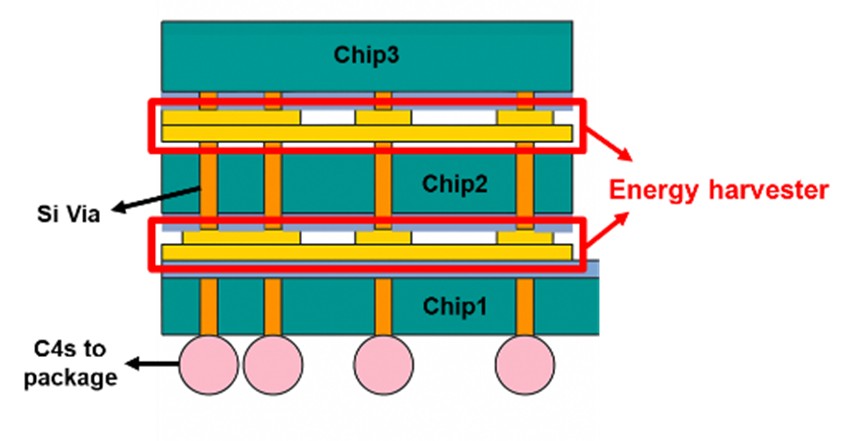

Pyroelectric Energy Recycle of Fluorite Hafnium Zirconium Oxide for 3D IC Package, Stacked Chip and BSPDN Application

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Product promotion、Display of scientific results

Trading preferences:Technical license/cooperation、New products development、Negotiate by self、Non-exclusive license

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!