igus focuses on high quality and sustainability in production - but how do sustainability and plastic go together? The explanation is quite simple: bicycle components made of plastic require much less energy during production than their aluminium or carbon counterparts, and the CO2 footprint is significantly smaller. Even after the end of the product life cycle, recycling is much easier than with competing materials.

In addition, recycled materials are already used in the production of igus bike components. The declared aim is to manufacture the products entirely from recycled materials and to take them back at the end of their service life. These are then used to manufacture new products - creating a circular economy. Another factor that should not be neglected: thanks to production in Cologne, the usual long transport routes by container ship are no longer necessary.

igus®是一家總部位於德國科隆的高性能運動塑膠產品製造商。自1964年以來,公司一直致力於研發和生產適用於機械動態應用的免保養的創新工程塑膠零件。旗下產品包括拖鏈、耐彎曲電線電纜、自潤軸承、免上油線性滑軌、螺桿技術、機器人和智慧感測器等,目的在幫助客戶精進技術和降低成本。由於我們大部分的產品採用射出製程製造,因此公司取名為igus® ( I ndustriespritz gus s,即工業用射出成型)。

1.Heat pump combined with desiccant for dehumidification & 2.Smart defrost control method & 3.Design of AIoT EMCS communication system & 4.System and Method for a Non-Intrusive Refrigerant Leakage Detection and Adaptive Method for Threshold Thereof

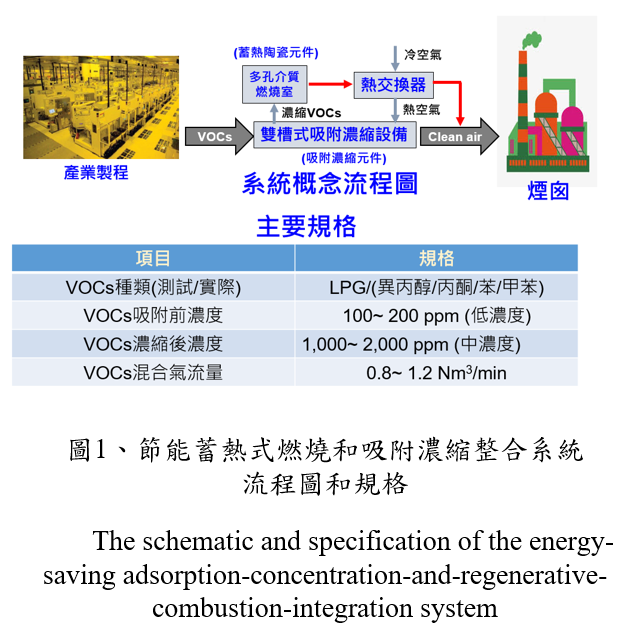

The integration of energy-saving regenerative combustion and adsorption system for disposing industrial volatile organic compounds

Water Treatment Application to generate and prolong enhanced hydrogen retention time at stabilized long-term pH increase of drinking water

The new material and application technology of weather-resistant and anti-corrosion solar photovoltaics frame in coastal field

Technology maturity:Mass production

Exhibiting purpose:Product promotion、Display of scientific results

Trading preferences:Negotiate by self

Coming soon!