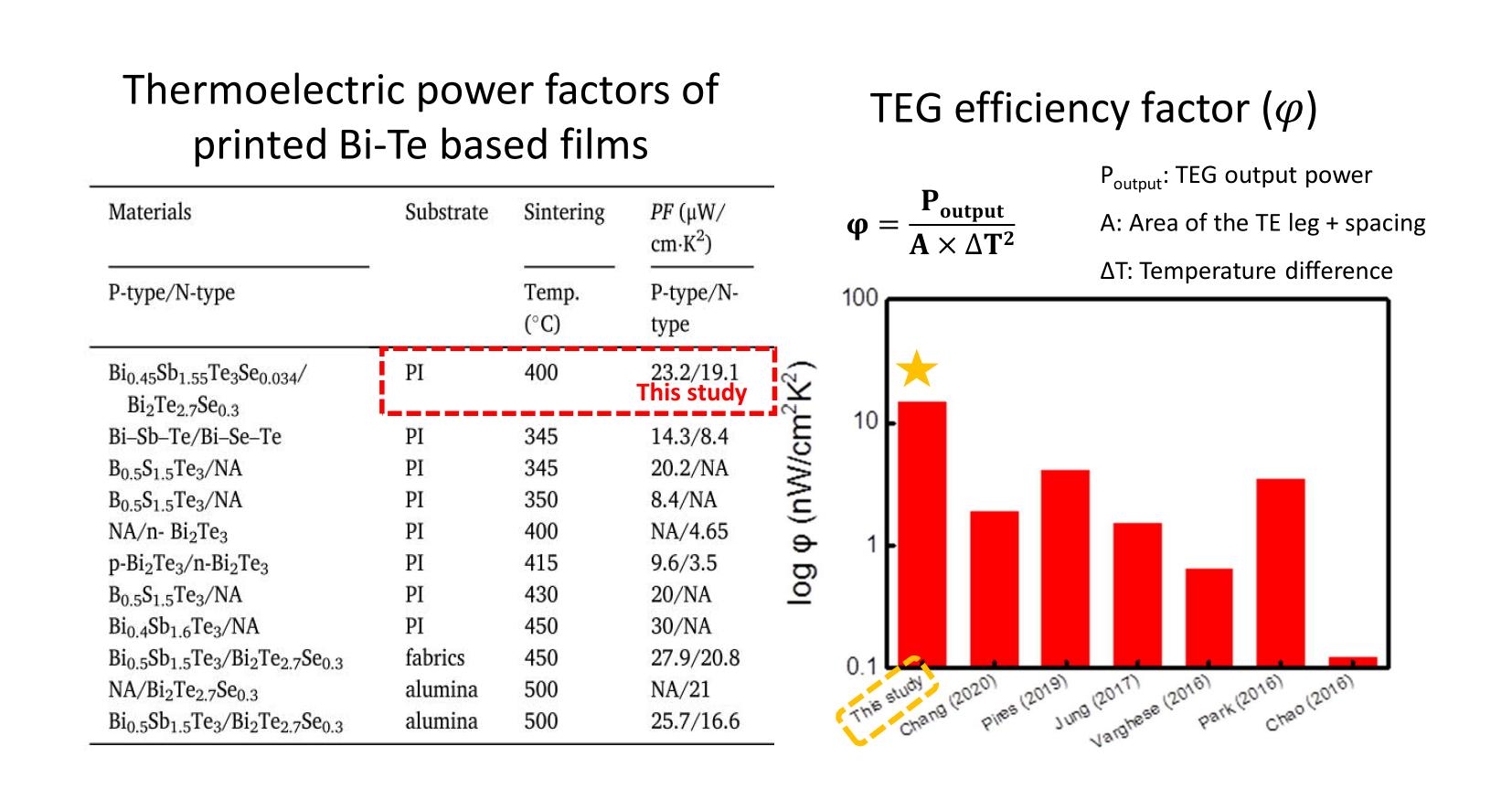

Thermoelectric generators (TEGs) can convert environmental thermal energy into electricity. A typical TEG is made of multiple P/N thermoelements joined by metal connectors in between two ceramic plates. Dispenser printing technology is highly suitable for making micro-TEGs (μ-TEGs) with thermoelement thickness (80 – 150 μm). The presented technology consists of three parts: (1) Optimization of printing ink; (2) Printing and sintering of thermoelements; (3) Demonstration of flexible μ-TEG. The sintered P- and N-type thermoelements show the power factor of 23.2 μW/cmK^2 and 19.1 μW/cmK^2, respective. An 8-paired μ-TEG can deliver a power of 68 μW under a temperature difference of 33 ℃. No performance degradation is detected for the flexible μ-TEG after 500 cycles of bending. A modular TEG is constructed to demonstrate LED powering and battery charging.

The Intelligent Cloud Platform for the Machinery Industry and on-premise Taiwan Machinery Standard Runtime networking technologies.

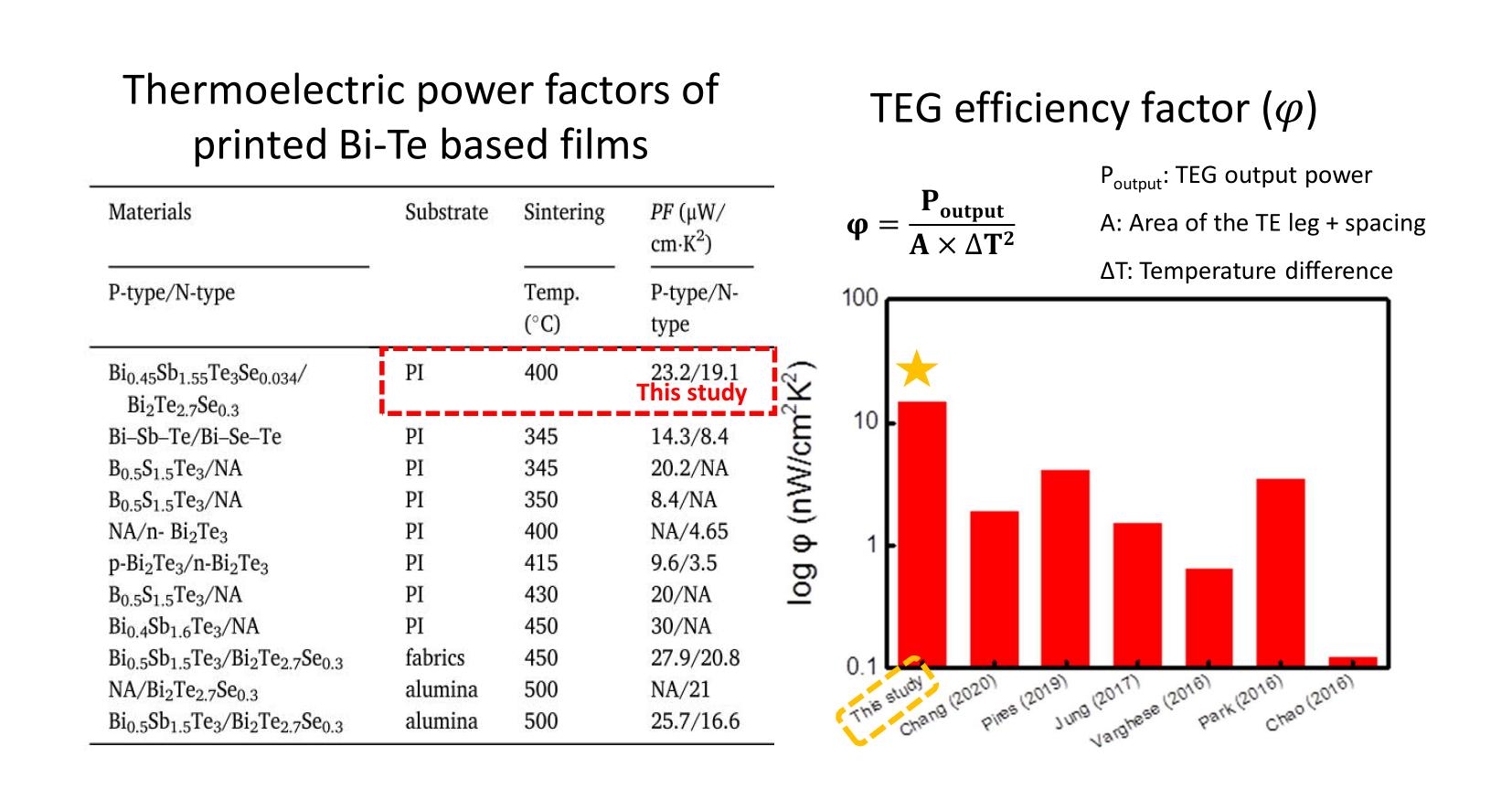

Highly flexible and stretchable piezoelectric nanogenerators application in wearable smart textiles

Development of a New Generation of Hydrogen Storage Tanks - Ultra-Thin Thermoplastic Winding Tape Process Technology

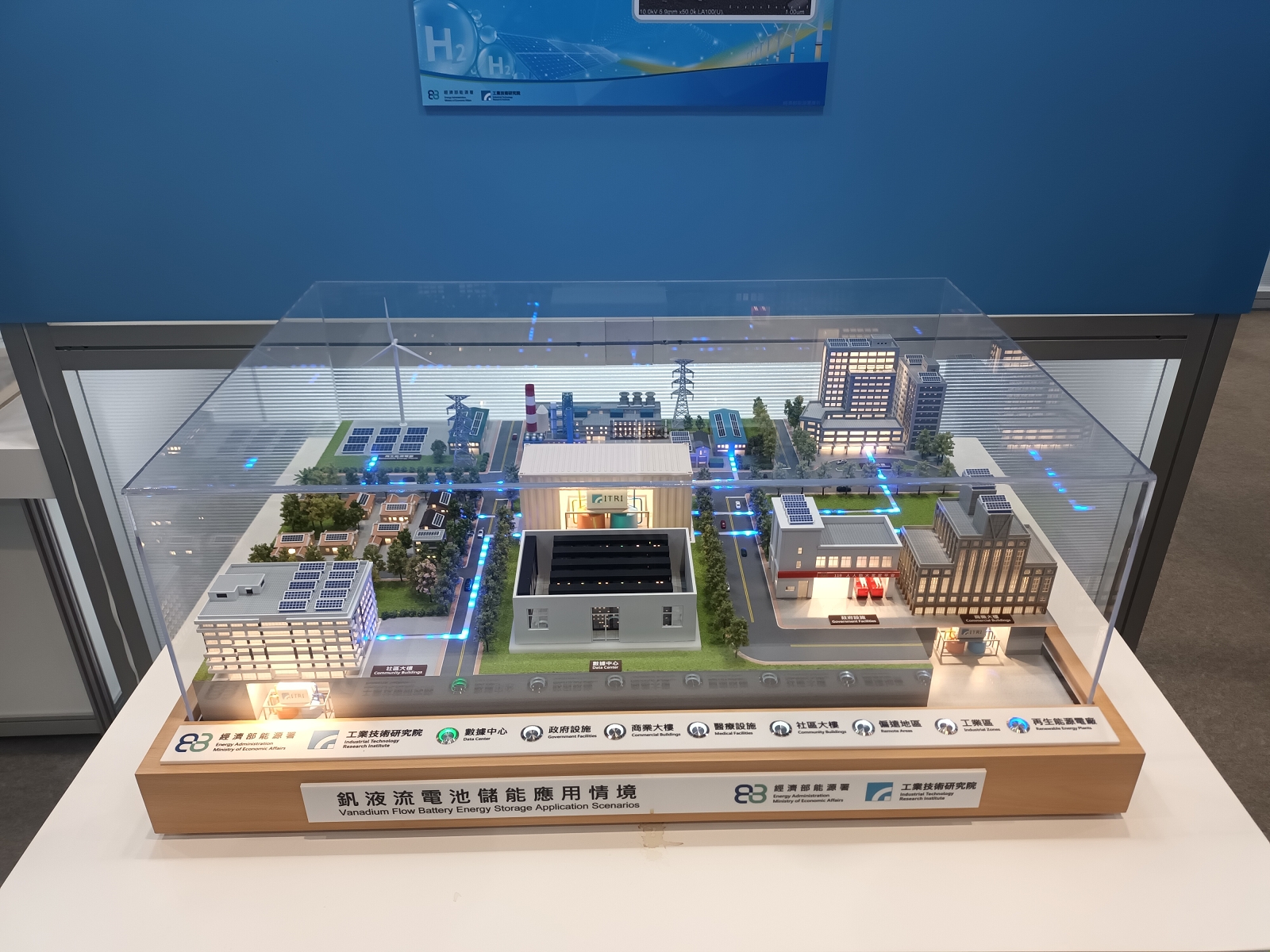

Vanadium flow battery energy storage application scenarios and key components - carbon felt modification technology

Technology maturity:Prototype

Exhibiting purpose:Display of scientific results

Trading preferences:Technical license/cooperation

Coming soon!