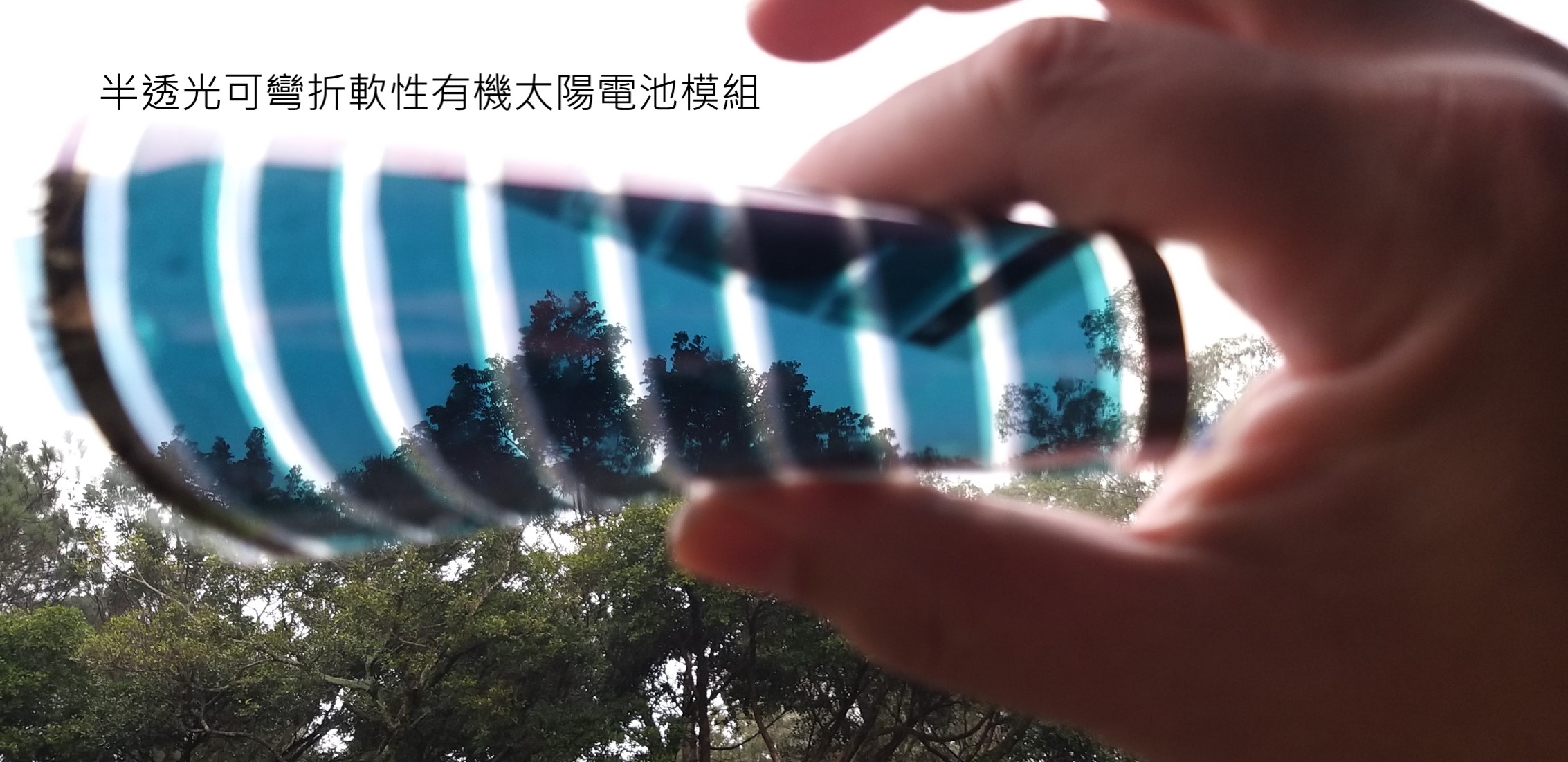

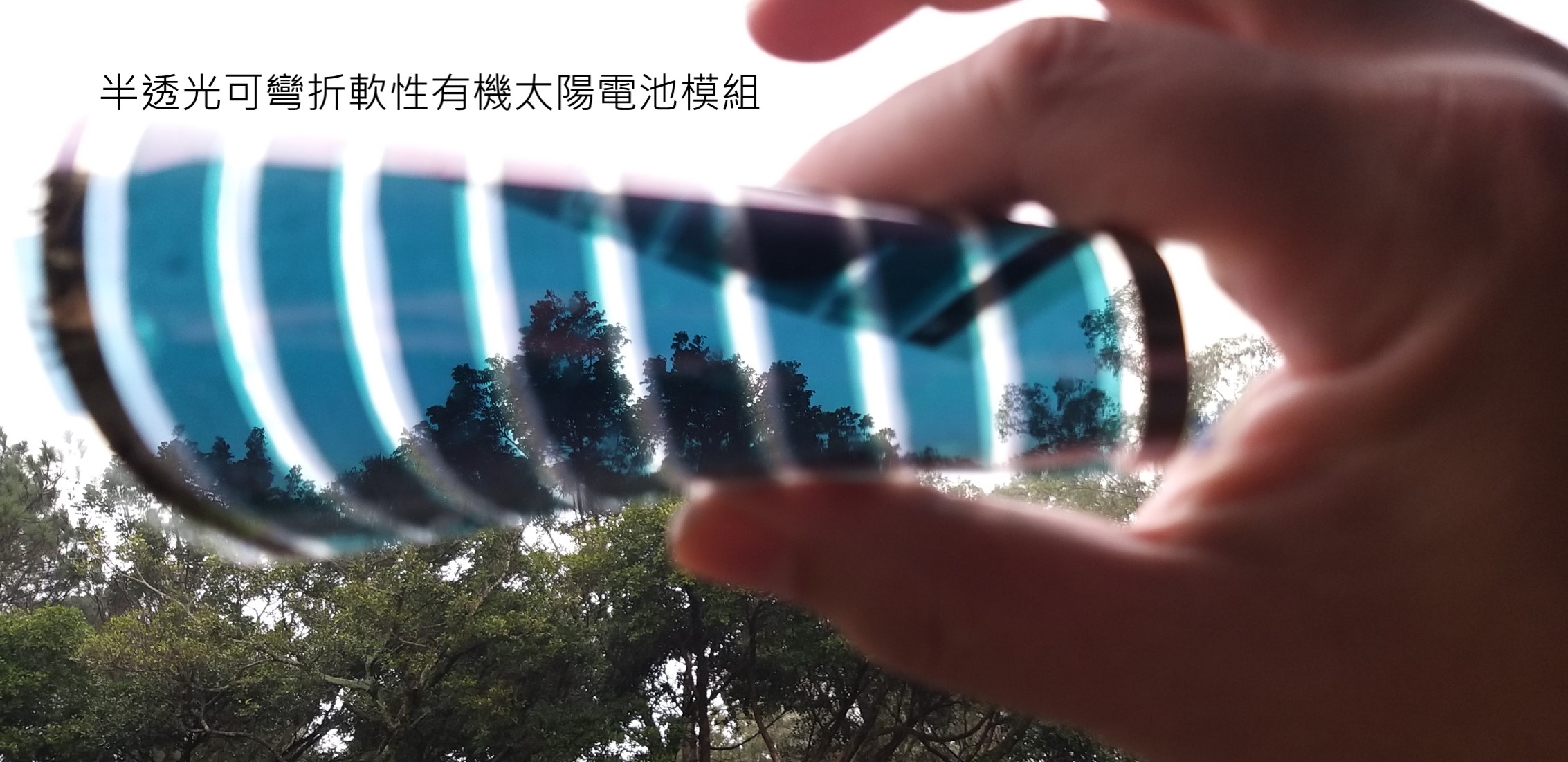

Low-carbon mass-production solution-coated fabrication and design of fl exible semitransparent organic photovoltaic module.

The flexible semi-transparent organic solar cell (OPV) module consists of

polymer nanostructure layer as the active layer and a light-weight flexible

substrate electrode. With the key technique of large-area solution coating

process, the active layer and charge transporting layer based on non-toxic

solution can be manufactured in ambient condition by using low-cost ind

ustrial coating machines or even ink-jet printers.

Currently, OPV researches mainly focused on the high efficient spin-coate

d opaque small-area devices on glass substrates. However, the disadvanta

ges of relative short lifetime of several hundred hours and high material c

onsumption cannot meet the requirements of commercial industrializatio

n. This technology develops an innovative Lab-to-Fab mass-production so

lution process that enlarges devices into large-area OPV modules, which

makes it a new energy source and can be integrated with various applicati

ons in the future.

The proposed technique breaks through the development limitation of tra

ditional OPV technology and has the following characteristics: (1) flexibilit

y, (2) light transmittance, and (3) high stability. Through the accelerated d

amp-heat test and the outdoor field test in greenhouse, the stability of th

e flexible transparent OPV module is verified. The trade-off performance

between the light transmittance, performance and stability of the propose

d OPV module is better than those efficiencies of the published OPV mod

ules.

Compared with the traditional silicon-based solar cell technology, the co

mpetitive advantages of OPV are as follows: (1) Carbon reduction and ene

rgy saving: The carbon emission of the OPV module is only 3-15 gCO2e/k

Wh. (2) Limitation of cost and installation: Compared with Silicon PV, the p

roposed flexible OPV module does not require supporting structural com

ponents, which may exceed the cost of module manufacturing. (3) Ease of

mass production and manufacturing.

Mission: Targeting nuclear safety, nuclear back-end, nuclear medicine, radiation applications for public welfare, as well as new energy and cross-field system integration as primary development pillars, NARI strives for pioneering advanced technologies and innovative R&D so as to make contribution to people's livelihood and well-being. Vision: Focusing on the research and development of atomic energy and its derivative technologies, NARI continuously innovates the problem-solving capability to help build a safe and resilient society.

Name:

Phone:

Address:No. 1000, Wenhua Rd., Longtan Dist., Taoyuan City 325, Taiwan (R.O.C.)

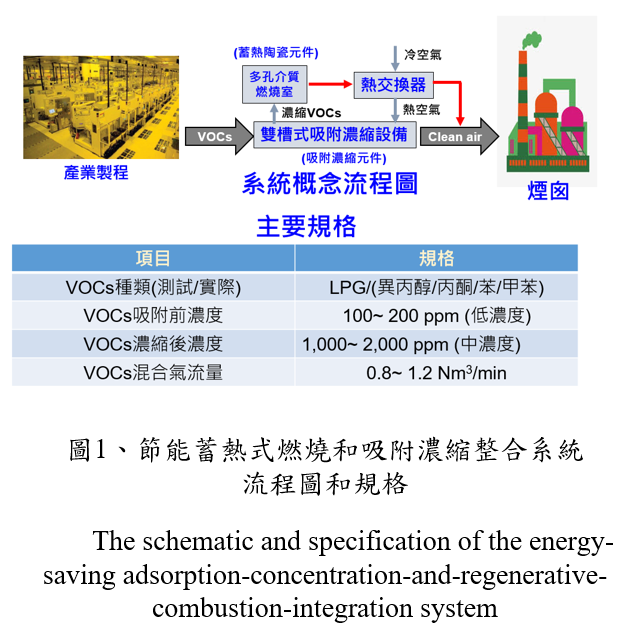

The integration of energy-saving regenerative combustion and adsorption system for disposing industrial volatile organic compounds

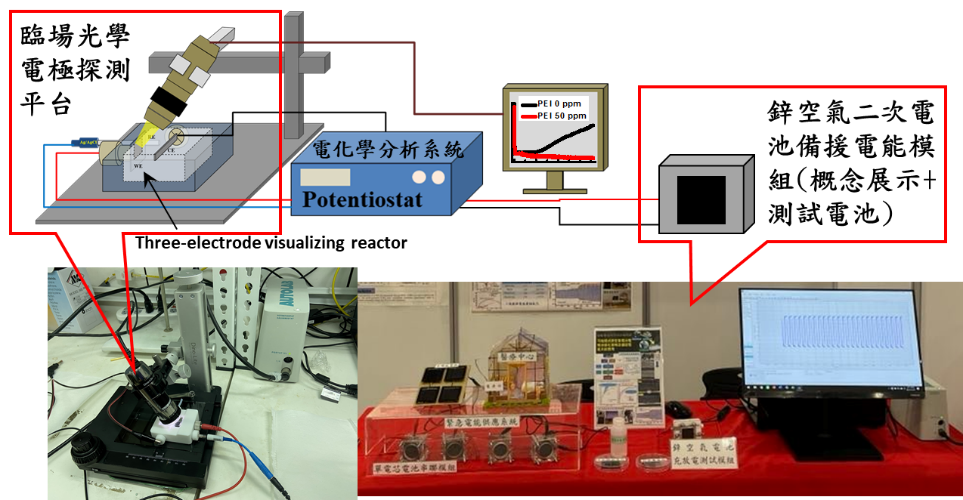

Portable in situ/operando optical microscopy technology for electrode reactions detection and applied in developing advanced high-performance zinc secondary batteries

Ultrasonic non-destructive test technology to commercial lithium-ion batteries of electric vehicles.

Generation of Low-Carbon Ozone and Negative-Hydrogen with Next-Generation Proton Exchange Membrane Water Electrolysis Technology

Technology maturity:Experiment stage

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!