Automatic palletizing system for egg packaging factory and its handling method for shipping cartons

_27.jpg)

_27.jpg)

The current palletizing methods for egg shipping containers vary by container sizes, pallet sizes, and stacking methods among different customers. These inconsistent conditions restrict the construction of automated systems, so the current palletizing way still depends on labors. Workers are prone to occupational injuries during long-term and heavy-load actions. In this project a conveyor connected all of the egg packaging lines throughout the whole factory to transport the egg cartons to the boxing zone. A boxing robot loads the cartons into shipping containers, then the containers are moved the pelletizing zone. A RFID reader recognize the RFID tag on the containers and a palletizing robot stacks them to the designated pallet positions according to the products’ corresponding stacking method.

National Ilan University was one of the first institutions of higher education in Taiwan. It was founded as the Taiwan Provincial Ilan School of Agriculture and Forestry on 12 May 1926. Since then, the name and focus of the institution have undergone a number of changes, from having been a five-year junior college (National Ilan Junior College of Agriculture and Technology), and a polytechnic college (National Ilan Institute of Technology). In 2003, the school was further reformed into its current status as a comprehensive university, offering BA, BS, MA and MS degrees in four colleges.

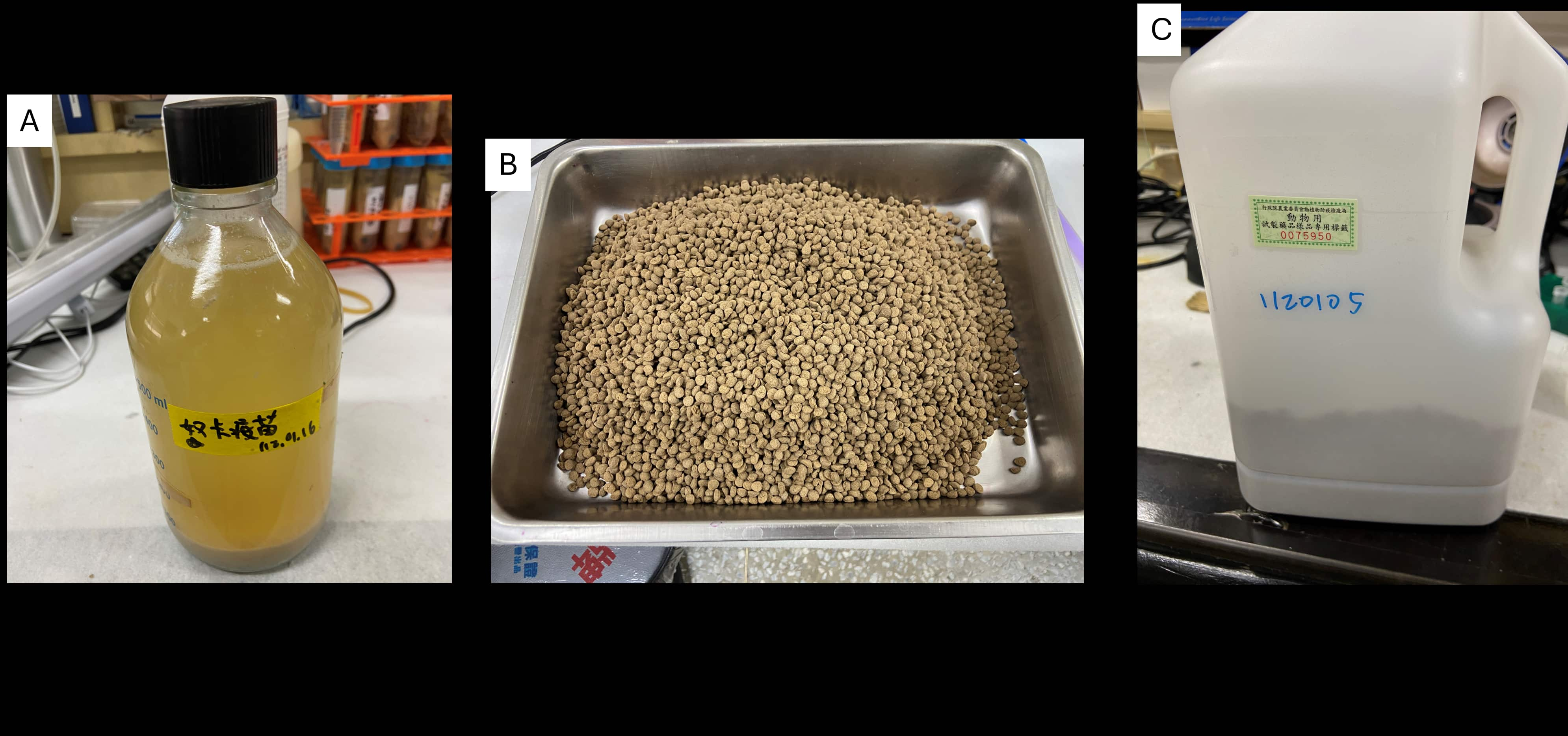

Compound fermentation microorganisms production technology for poultry manure composting and its application method

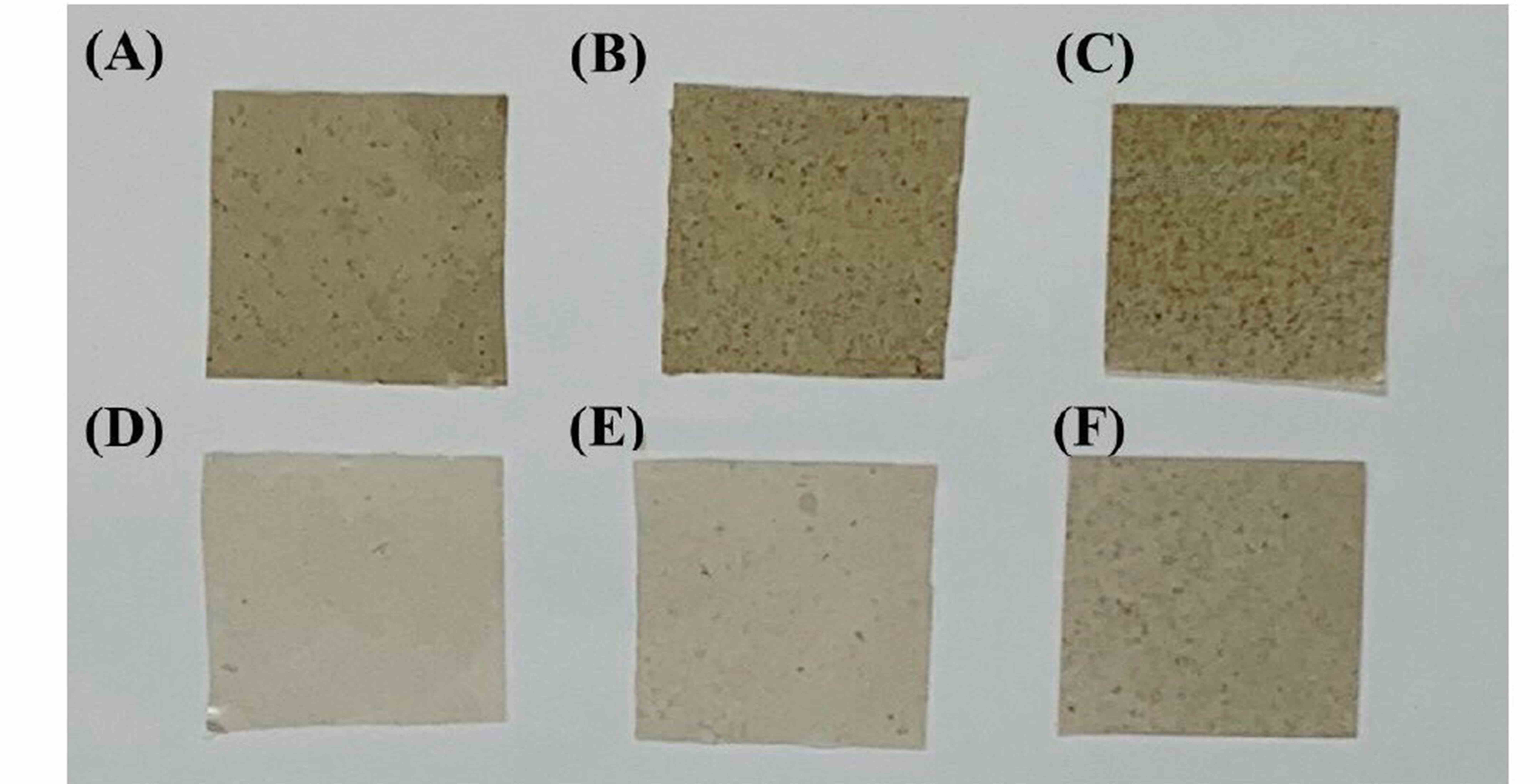

Improved processing technology for green banana flour and its application in film production

AI-Automated Poultry Weight Monitoring System Poultry feature organ image recognition Development of Chicken Voiceprint Warning System and Light Disturbance System

Vaccine composition against bacteria and biofilms, preparation method thereof, and applications

Technology maturity:Mass production

Exhibiting purpose:Technology transactions、Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!