Atmospheric Pressure Laser Coupling Multiphase Reactive Fluid Green 3D Nano/Micro Direct Synthesis and Patterning Technology

3D Electronics is the mainstream of the next-generation optoelectronic pr

oducts. At the same time, low-carbon manufacturing is a global trend. Her

e we present an innovative green manufacturing technology that deposit

and pattern high-density complex circuits and functional materials on 3D

freeform substrates based on a laser assisted reduction and patterning pr

ocess in multi-phase reactive fluids. Laser Direct Synthesis and Patterning

(LDSP) uses laser scanning to accurately and selectively reduce and deposi

t metal fine lines in ionic aqueous solutions. Laser Atmospheric Pressure P

lasma Jet (LAPPJ) integrates laser with atmospheric plasma to deposit Tra

nsparent Conductive Oxide fine patterns on optical substrates. By switchin

g the reaction precursor solution, a variety of functional materials can be

quickly synthesized, patterned and thermally treated on the designated su

bstrate in a Single-Step process. This process can be performed at atmosp

heric environment, which further reduces the energy, resources and cost f

or the manufacturer. Owing to the high selectivity of laser process, this tec

hnology is especially suitable for making flexible wearable devices, such a

s flexible batteries, flexible displays, wearable sensors and electronic pape

r. In addition, with a designed laser module, the hybrid process of laser abl

ation, cutting, drilling, and laser deposition, patterning, via filling etc. can

be realized on the same manufacturing system, thus further reduce costs,

shorten process time, and increase the precision as well as the stability of t

he process. Combined with automatic optical inspection, this process can

also be applied for circuit repair. Different from the general circuit repair p

rocess that combines jet printing and laser heat treatment using nanopart

icle ink, this process technology uses a particle-free aqueous ionic precurs

ors as a material source. Thus, the overall process efficiency, cost and carb

on emissions can be greatly improv

National Tsing Hua University (NTHU), established in 1911 and located in Hsinchu, Taiwan, is one of the top research universities in the country. NTHU offers a wide range of programs in fields such as engineering, science, management, and humanities. The university is known for its strong emphasis on innovation, research excellence, and fostering global perspectives. With a commitment to academic rigor and interdisciplinary collaboration, NTHU plays a key role in advancing knowledge and technological development, contributing to both Taiwan’s growth and the global academic community.

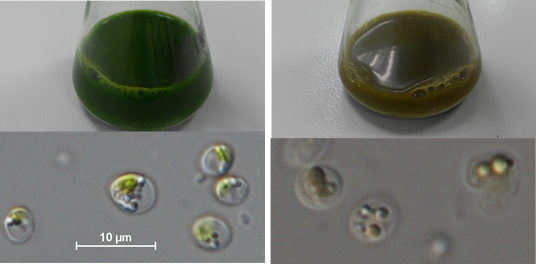

Method for manufacturing an active substance for inducing self-lysis in microalgae cells, active substance obtained therefrom, and method for inducing self-lysis in microalgae cells

Method for manufacturing an active substance for inducing self-lysis in microalgae cells, active substance obtained therefrom, and method for inducing self-lysis in microalgae cells

Method for manufacturing an active substance for inducing self-lysis in microalgae cells, active substance obtained therefrom, and method for inducing self-lysis in microalgae cells

Method for manufacturing an active substance for inducing self-lysis in microalgae cells, active substance obtained therefrom, and method for inducing self-lysis in microalgae cells

Technology maturity:Experiment stage

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!