High Precision Maskless Lithography System for Advanced IC Substrates and Packaging

Photolithography plays a dominant role in global high-technology industry. Conventional UV exposure methods are mostly using photomasks, which can be time/cost-consuming ad lack the manufacturing flexibility. In recent years, due to the digital light processing (DLP) technology developed by TI company, maskless lithography UV exposure systems are emerging quickly and are gradually replacing conventional UV exposure methods. However, the maskless UV exposure systems on the market now are all dominated by foreign companies (Germany, Japan, and China, for example), and there is no domestic company in Taiwan which is capable of developing her own maskless lithography system. This poses a serious threat and challenge to Taiwan’s electronics industry. This project aims at developing a high-resolution maskless lithography system with a smallest patterning linewidth down to 5~10 um. It is because we are going to adopt a new design of UV patterning method based on the concept of “aspheric microlens array, UV point array, and obliquely scanning scheme”, which allows extremely fine pattern resolution with similar UV energy efficiency at the same throughput. Based on our proprietary designs and components, the performance of this new type of maskless lithography system can quickly exceeding its competitors on the market and creates its own market share.

The Engineering and Technology Promotion Center (ETPC) has been established in 1965 at National Cheng Kung University. It is the exclusive unit continuously supported by the Department of Engineering and Technologies, National Science and Technology Council under projects. The main missions of ETPC are to integrate and promote the academic research achievements, especially in engineering areas to the industry, and to upgrade/add the values of technologies in production development. This center plays an important role as a “bridge” between the academia and industry. In ETPC, an "eTop-Engineering and Technology Open Promotion platform" (www.etop.org.tw) has been established and managed online since 2011. In which, the reports of research projects supported by the Department of Engineering and Technologies, has been digital archived for reference since 2005.

Safety Monitoring System using Intelligent Image Recognition on Crane Operation Areas and Hoisting

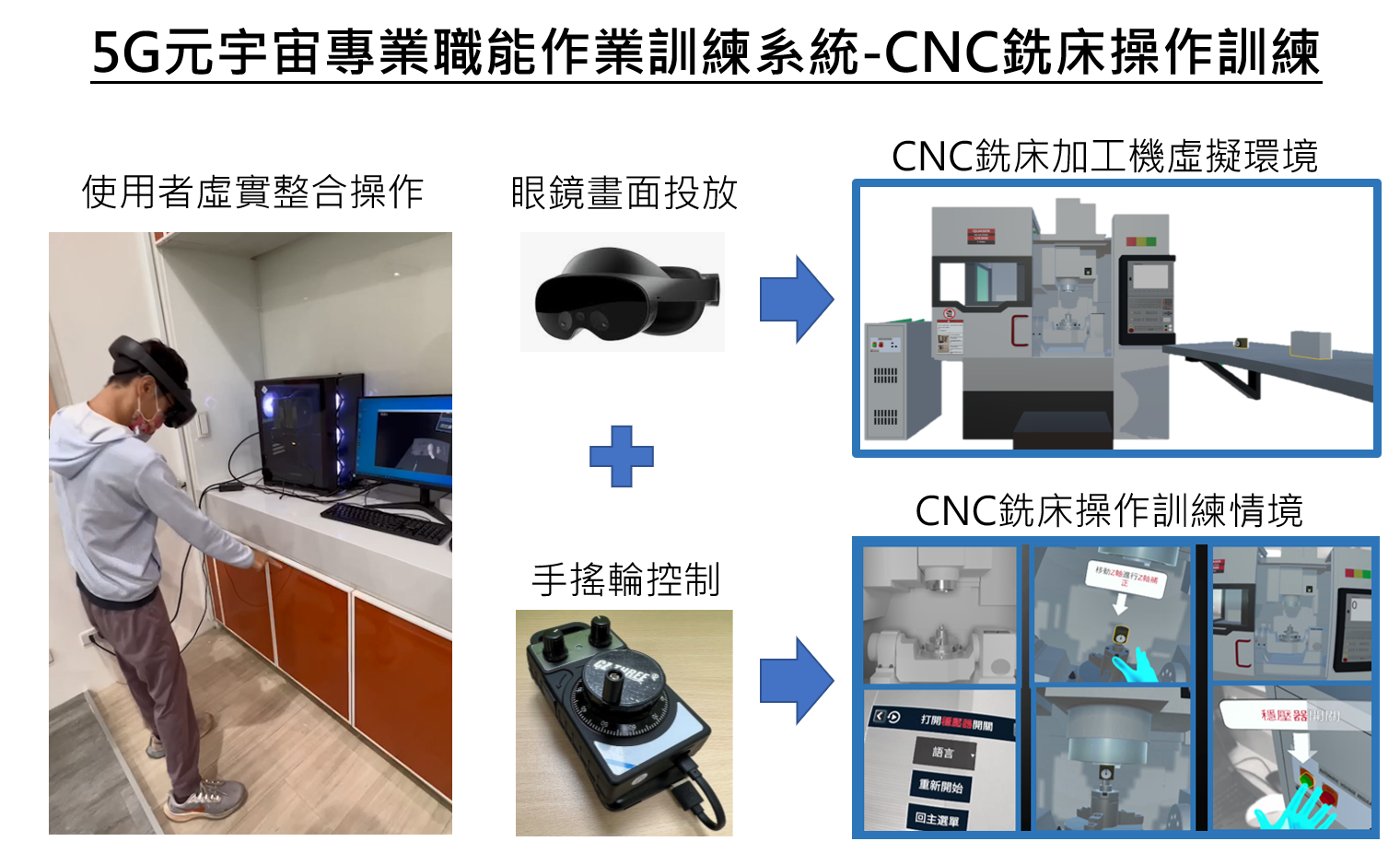

5G Metaverse Professional Job Skills Training System - CNC Milling Machine Operation Training

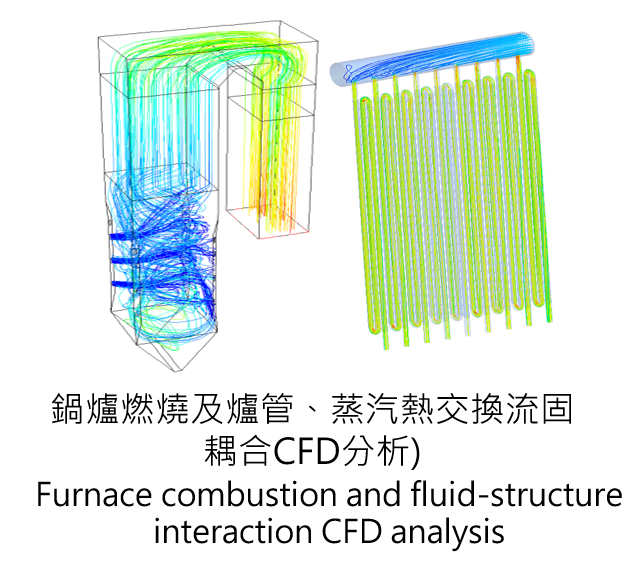

Health Monitoring and Assessment System for Boiled Tube of Fossil-Fuel Power Plant

Application of Advanced Intelligent Feature Capture for Machine Tool Cutting States Monitoring and Prediction

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Negotiate by self、Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!