Fabrication of Seamless Roller Molds by Fiber Array and Digital Light Processing

Roller molds, particularly seamless roller molds, are the key components in a roll-to-roll (R2R) rolling imprinting system which is known for the most effective method for large-area micro-manufacturing. This research has developed an innovative method and implemented it into a prototype system for achieving arbitrary and complicated patterns of 3D microstructures on the surface of a metallic roller. It basically transforms conventional planar photolithography on to the cylindrical surface of a roller through UV exposure, photoresist developing, and etching processes. This roller manufacturing system consists of digital light processing (DLP) technologies, arrayed fiber optics, microlens array, and precision servo-controlled motion systems. Using this arrayed UV beam pen system, we are able to achieve UV patterning on a roll’s surface and finally obtain a seamless roller mold for roller imprinting.

The Engineering and Technology Promotion Center (ETPC) has been established in 1965 at National Cheng Kung University. It is the exclusive unit continuously supported by the Department of Engineering and Technologies, National Science and Technology Council under projects. The main missions of ETPC are to integrate and promote the academic research achievements, especially in engineering areas to the industry, and to upgrade/add the values of technologies in production development. This center plays an important role as a “bridge” between the academia and industry. In ETPC, an "eTop-Engineering and Technology Open Promotion platform" (www.etop.org.tw) has been established and managed online since 2011. In which, the reports of research projects supported by the Department of Engineering and Technologies, has been digital archived for reference since 2005.

Application of Advanced Intelligent Feature Capture for Machine Tool Cutting States Monitoring and Prediction

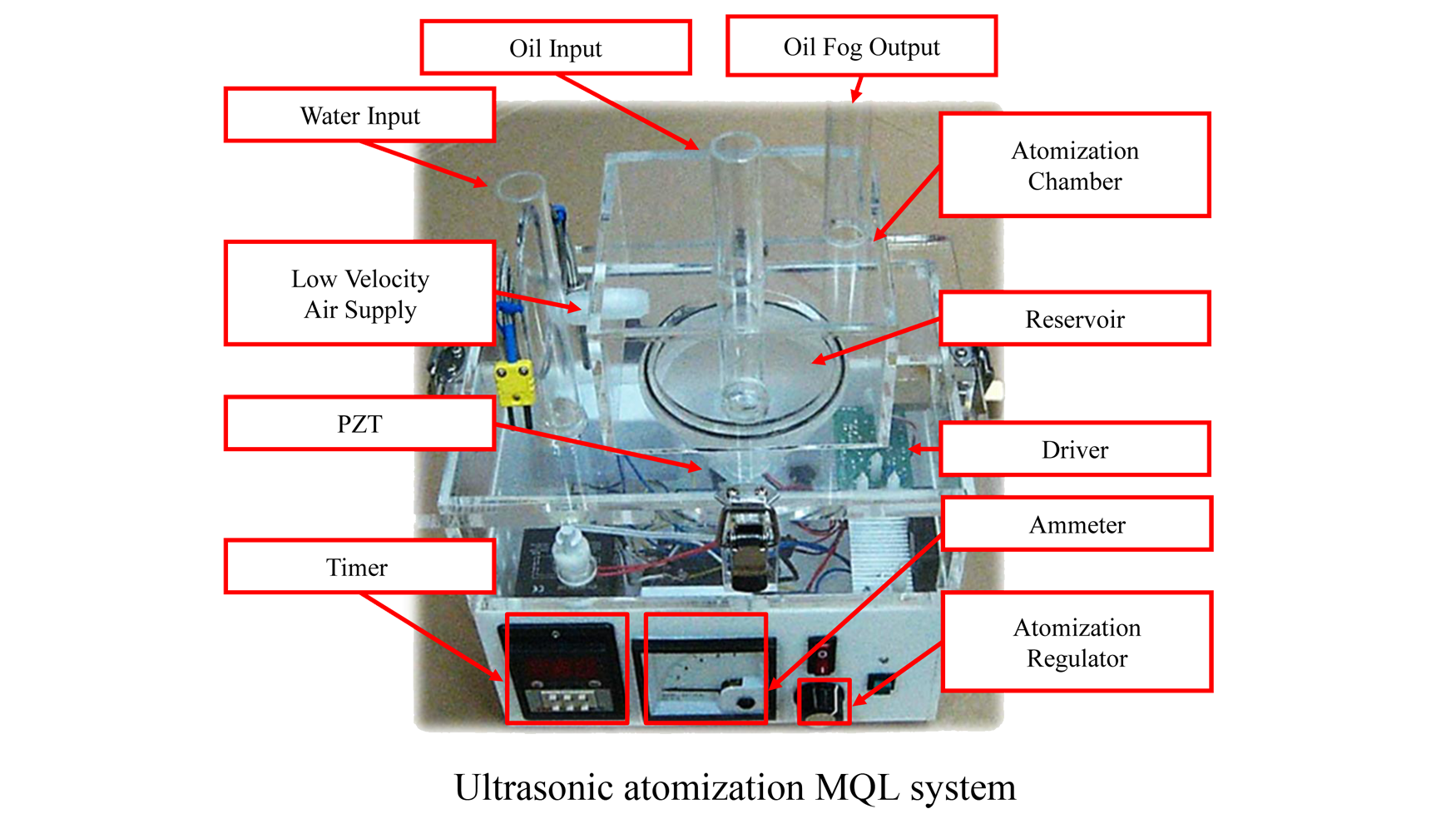

Nanofluid/ultrasonic atomization micro-lubrication system development and application intelligent modeling method to improve the multiple quality characteristics of the micro-machining process research and optimal prediction model establishment

Combined Water Treatment Technology for non-electrical production of Alkaline, Hydrogen-rich drinking water with prolonged retention rate of target value frames

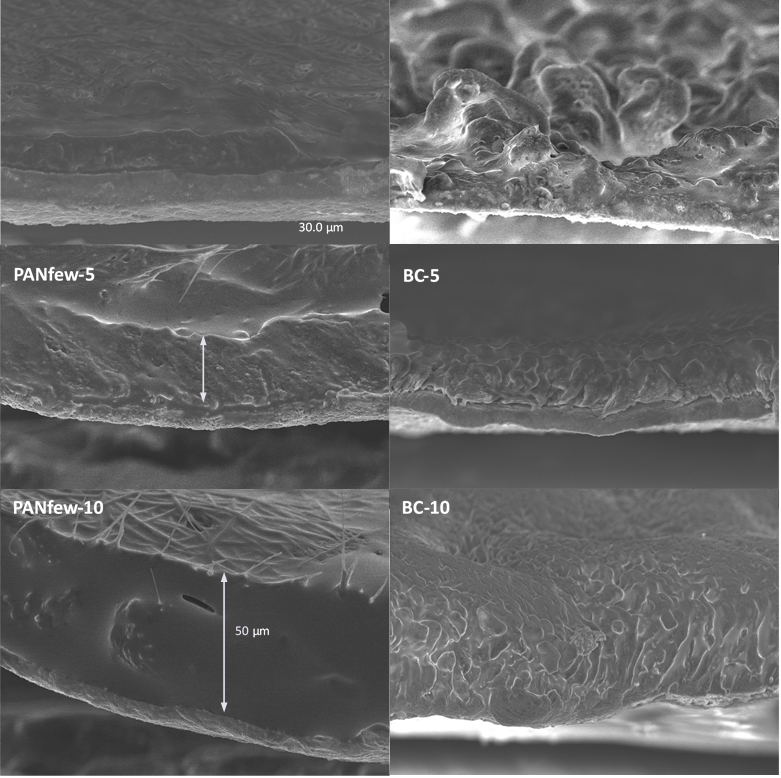

Fabrication of high-capacity and high-safety lithium half-cells and pouch cells was achieved through the integrated development of anode materials, protective interlayers, and electrolyte systems.

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Negotiate by self、Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!