Nanofluid/ultrasonic atomization micro-lubrication system development and application intelligent modeling method to improve the multiple quality characteristics of the micro-machining process research and optimal prediction model establishment

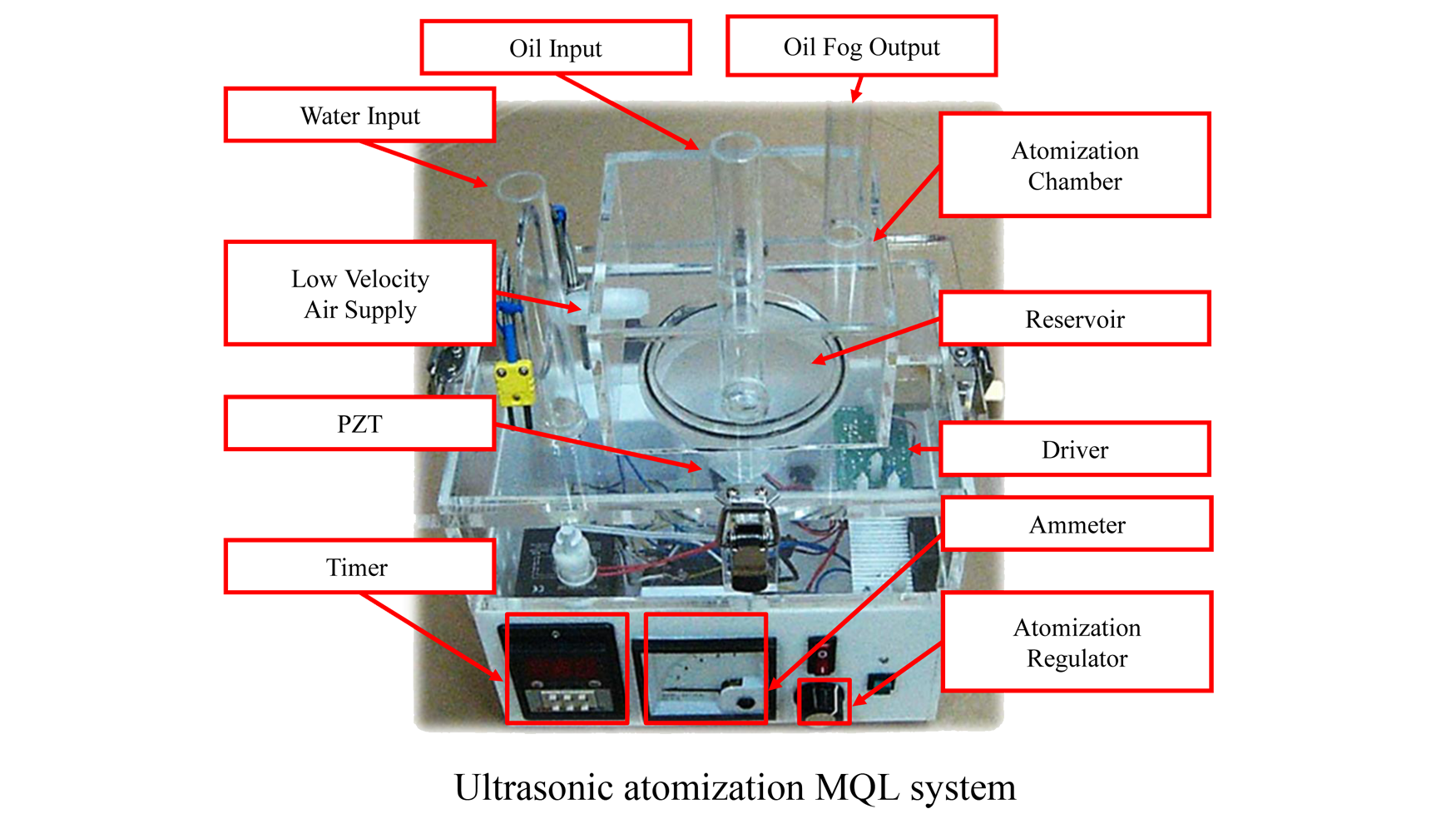

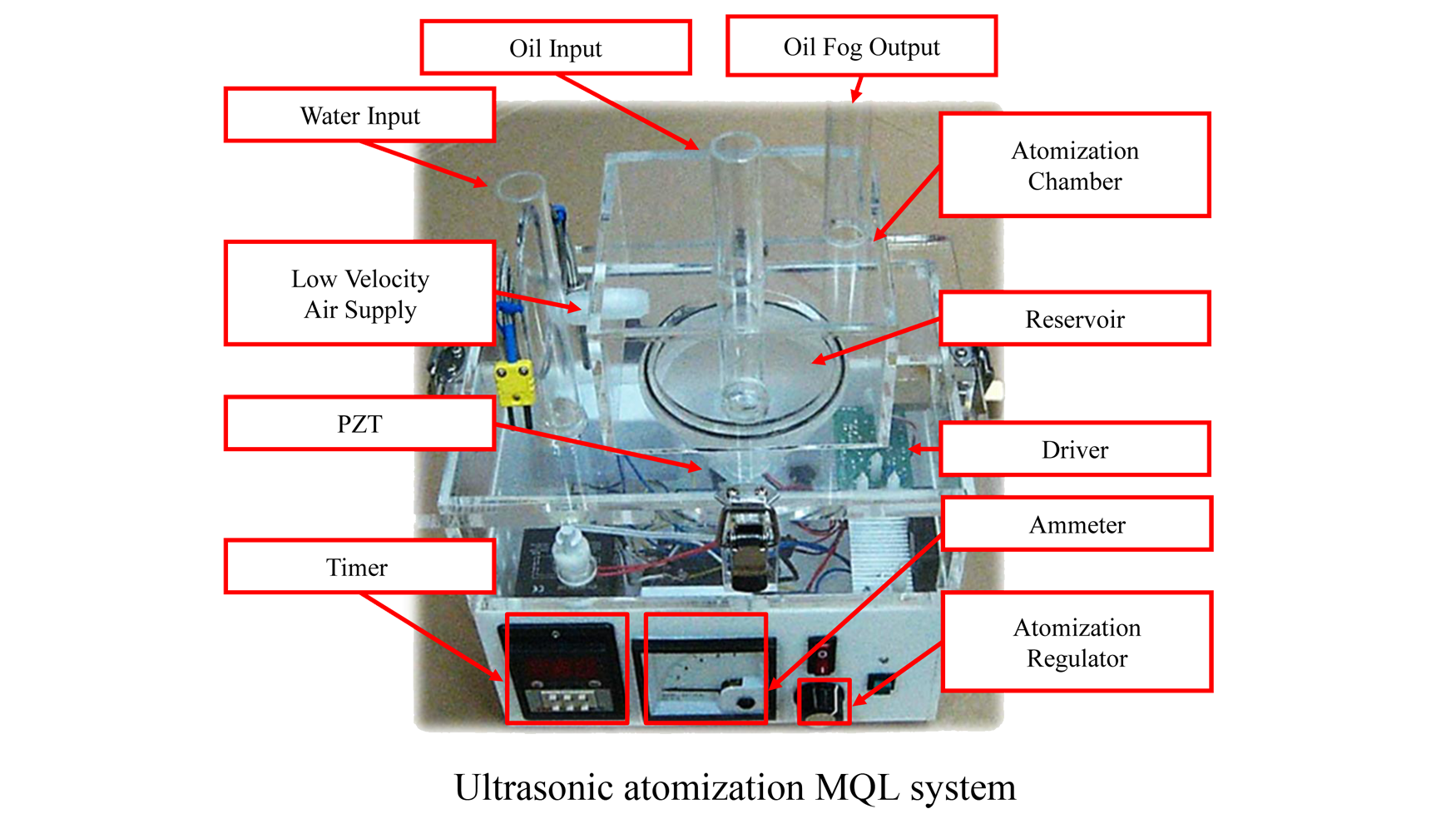

This technology's nanofluid/ultrasonic atomization micro-lubrication system is different from the general micro-lubrication technology that uses high-pressure air atomization. It is first to use cavitation characteristics to disperse a small amount of nanofluid into microscopic particles and effectively disperse the bonding and agglomeration of nanoparticles due to the Van der Waals force. The second stage of atomization is carried out through high-pressure air. The oil mist particles of the nanofluid can easily enter the micro-machining cutting area for cooling and lubrication.

This technology is the first in the world. It first uses cavitation to disperse the nanofluid. It then uses high-pressure air for the second stage of atomization. The liquid nanofluid can be converted into a gaseous state and can more easily enter the cutting area for cooling and lubrication. The detailed design of the ultrasonic atomization system has a special spacer film and a double container to avoid the deposition of nanoparticles, which reduces the efficiency of nanofluids. Combining this technology with a variety of intelligent modeling methods can effectively greatly improve the quality and benefit of various processes.

This technical team developed a series of nanofluid micro-lubrication equipment. After years of R&D and improvement and actual verification with several cooperative manufacturers through cooperation plans, it can greatly increase the demand for green manufacturing technology in micromachining. The research and development results have a substantial effect in reducing the environmental pollution in the industry in terms of green technology to reduce environmental pollution, a large amount of cutting waste liquid recycling and energy consumption, machine tool cutting fluid pump energy consumption has a significant reduction, and also has a substantial contribution to the development and improvement of industrial technology.

線上展網址:

https://tievirtual.twtm.com.tw/iframe/ef794f15-f326-4f41-bed4-8f36360105c9?group=23bfb1fa-dd5b-4836-81a1-4a1809b1bae5&lang=en

National Pingtung University of Science and Technology offers an excellent opportunity for students to study a wide range of subjects with well developed departments and graduate institutes in four academic colleges including Agriculture, Engineering, Management, and Humanities and Social Sciences. In order to integrate theory with hands-on learning opportunities, NPUST has well equipped teaching and practice facilities, a library comprising over 300,000 volumes of books, access to various electronic databases and audio-video facilities, and optical fiber and wireless internet network connectivity to every corner on campus. The university also houses the NationalBotanical Garden , the Center for Wildlife Conservation and Management, the Art and Culture Industry Innovation and IncubationCenter , various exhibition farms, specimen collection centers, and a large, well equipped gymnasium. NPUST is an excellent place that provides a comprehensive teaching-learning community for our faculty and students. In the past 5 years, academic research achievements at NPUST have been distinguished as being among the top 15 universities on the accumulated scores of impact factor weights based on the WOS journals in the fields of agriculture sciences and ecology and environment sciences. NPUST is also on the list of the top 15 universities in total publication numbers and citation frequencies in the fields of agriculture sciences, plant and animal sciences, immunology and microbiology, ecology and environment sciences, and earth sciences. The achievements are exceptional. Recently, NPUST has successively been awarded funding for the “Program for Promoting Academic Excellence of Universities” by the Ministry of Education for several years. NPUST has utilized this funding to devote herself to create an even better educational and learning environment, and to continue to promote instructors’ teaching quality and students’ learning achievement in order to achieve our goal of endowing graduates with “holistic”, “professional”, and “international” frames of mind.

Name:Wei-Tai Huang

Phone:0937332661

Address:1, Shuefu Road, Neipu, Pingtung 91201, TAIWAN

Creating a Multi-Faceted Utilization Model for Remote Healthcare-Intellig ent Healthcare Technology with Multi-Ethnic Adaptability

Safety Monitoring System using Intelligent Image Recognition on Crane Operation Areas and Hoisting

Application of Advanced Intelligent Feature Capture for Machine Tool Cutting States Monitoring and Prediction

Fabrication of high-capacity and high-safety lithium half-cells and pouch cells was achieved through the integrated development of anode materials, protective interlayers, and electrolyte systems.

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation、Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!