Although the heterojunction solar cell has developed rapidly, it still has many problems. First, each step of the production process is very strict requirements, such as: Amorphous silicon thin film growth quality requirements are high and the surface of the silicon need very clean. Second, the amorphous silicon film cannot withstand the higher temperature of the subsequent process, so the latter process must use high-cost low-temperature materials. The tunneling heterojunction solar cell, it replaces the intrinsic amorphous silicon layer of an ultra-thin oxide layer. It has more stable characteristics, lower cost, and more suitable for mass production. The key is the use of furnace tubes and traditional sputtering technology to avoid the use of expensive plasma-assisted chemical vapor deposition (PECVD) or reactive plasma deposition (RPD) equipment. At present, we have been able to fabricate tunneling heterojunction solar cells with an open circuit voltage of more than 700 mV and an efficiency of 23%.

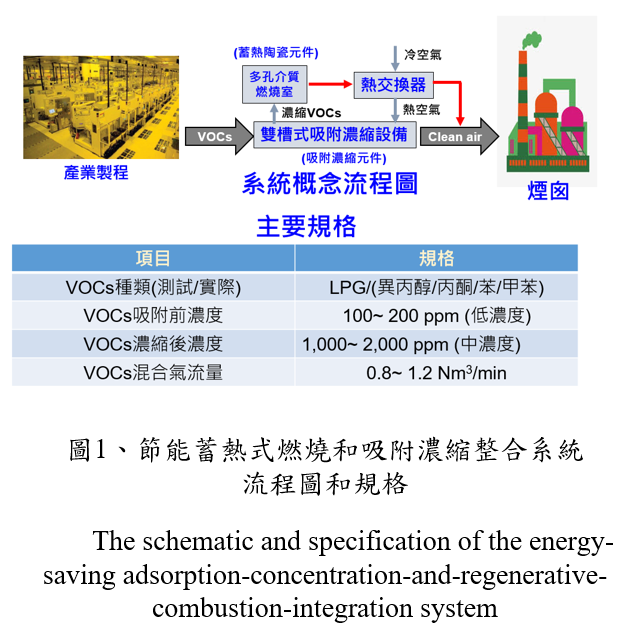

The integration of energy-saving regenerative combustion and adsorption system for disposing industrial volatile organic compounds

The tunneling heterojunction silicon solar cell

The tunneling heterojunction solar cell

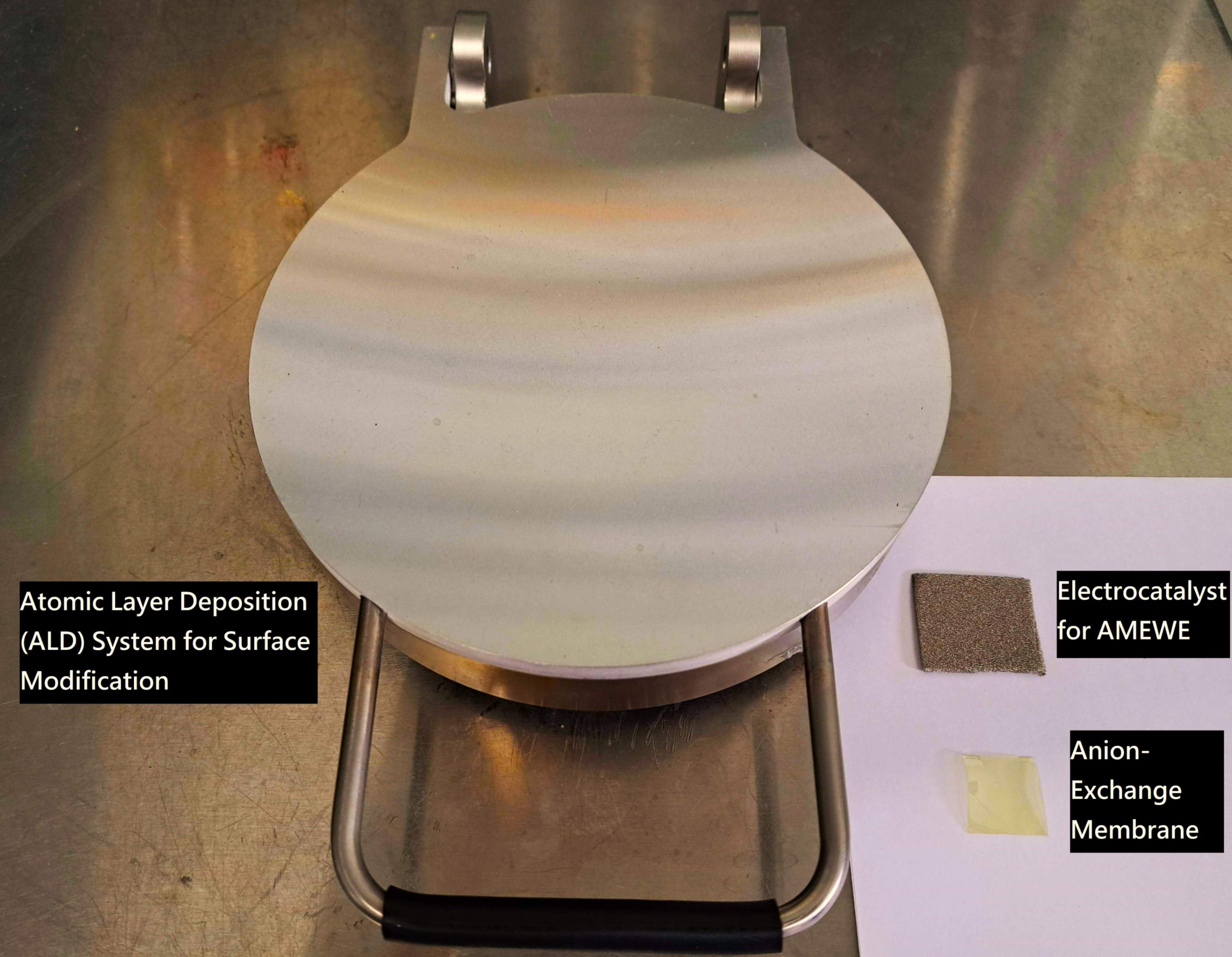

High practicality surface modification technology for enhancing hydrogen production via water electrolysis and solid-state hydrogen storage efficiency

Technology maturity:Prototype

Exhibiting purpose:Technology transactions、Patent transactions

Trading preferences:Technical license/cooperation、Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!