High-Entropy Non-Sparking, Anti-Bacteria, and High-Endurance Alloy Technology

"High entropy materials were proposed and developed by Professor Jien-Wei Yeh in 1995. He named, defined, and elucidated “High-Entropy Alloys,” as well as established High-Entropy Materials Center to develop critical materials for smart machine, green technology, biomedical technology, and national defense. Alloys with high strength, corrosion resistance, and anti-bacterial capability are also developed for manufacturing knives, door handles, handrails, etc. to prevent infection during the post-epidemic era.1. Non-sparking tools and stainless anti-bacteria copper knife

Non-sparking and beryllium-free high-strength medium-entropy alloy has been developed to substitute Cu-Be alloy for non-sparkling tools in consideration of the high cost and toxicity of beryllium. It can be also used in making knives and cutting boards having anti-bacteria function.

2. Bearing for oil well

High-entropy alloy with low cost and superior performance has been developed to replace high cobalt Stellite® 6 alloy for bearings used in submerged pumps in oil well.

3. Turbine engine

High-entropy superalloys have been developed to have superior strength, density, cost, ductility, and high-temperature strength over traditional superalloys. They can be used in turbocharger and turbine engine.

1. High-strength copper alloy - Non-sparking tools and stainless anti-bacteria copper knife

It can be used in tool industries producing non-sparking hammers, wrenches, screwdrivers, pliers, and shovels. It can also be used in commodities industries producing anti-bacteria knives, forks, bowls, scissors for raw foods, straw, etc.

2. Extreme high-entropy alloy - Bearing for oil well

It can be used in industries including oil well, energy, machine, chemical plant, geothermal power plant, etc.

3. High-entropy superalloy - Turbine engine

It can be used for transportation industries producing drone, micro-turbine engine, generator, turbocharger, etc.

"

National Tsing Hua University (NTHU), established in 1911 and located in Hsinchu, Taiwan, is one of the top research universities in the country. NTHU offers a wide range of programs in fields such as engineering, science, management, and humanities. The university is known for its strong emphasis on innovation, research excellence, and fostering global perspectives. With a commitment to academic rigor and interdisciplinary collaboration, NTHU plays a key role in advancing knowledge and technological development, contributing to both Taiwan’s growth and the global academic community.

Name:游江春

Phone:(03)571-5131 ext. 35373

Address:No. 101, Sec.2, Kuang-Fu Road, Hsinchu 30013

Development of Low Carbon Emission Polyester Elastomer and Shoe Application Technology

.png)

Lightweight and high-performance aluminum alloy and composite technology for vehicles

The Method for Preparing A Surface Modification Coating of High Performance Metal Bipolar Plates

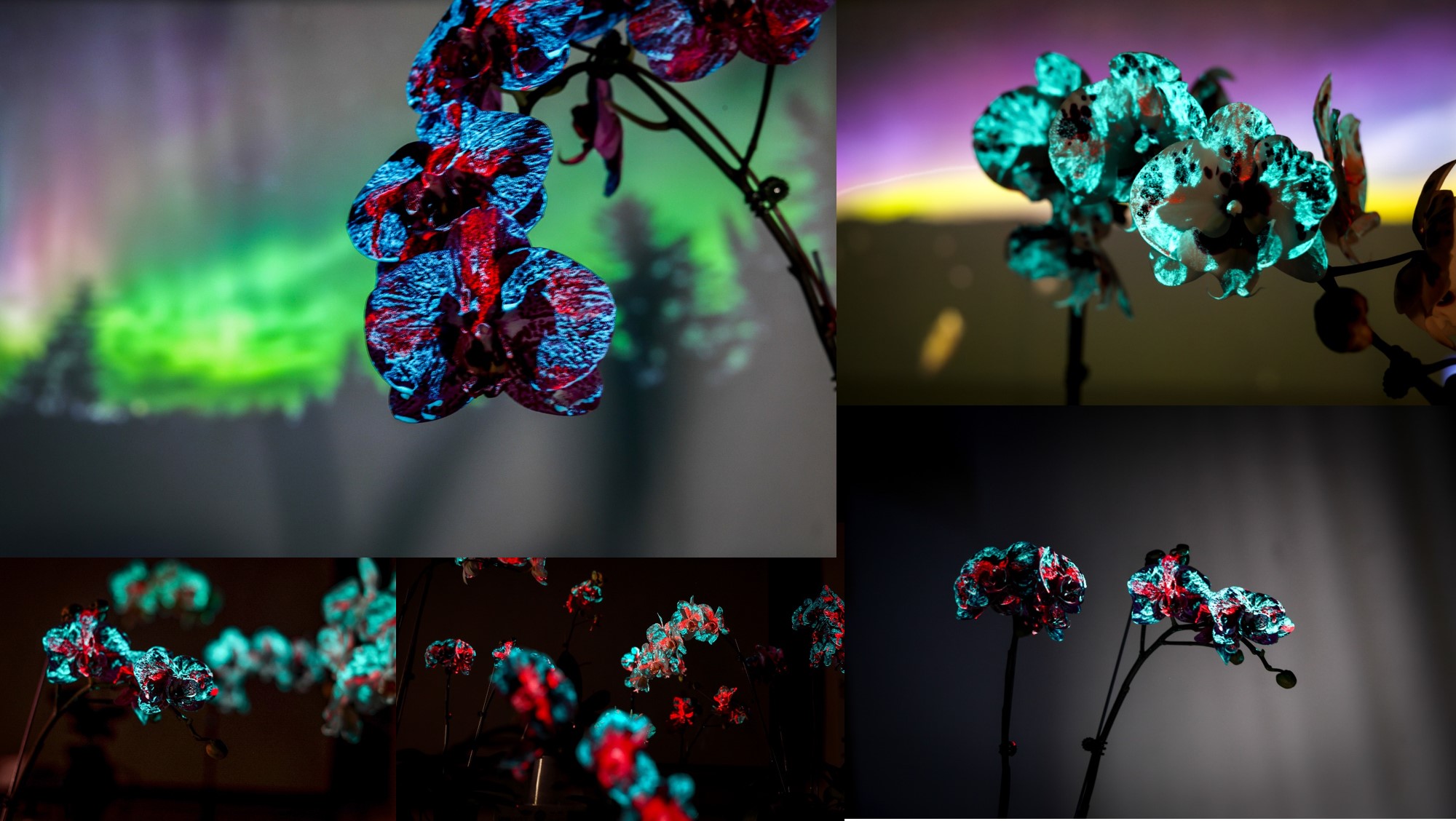

Luminous Aurora Orchid Controlled High Entropy Materials in Indoor Carbon Reduction Technology

Technology maturity:Experiment stage

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!