Key Technology for Advanced Industry 4.0: Advanced Intelligent Manufacturing Cell, 3D Printing Design Systems, AI Expert System for Friction Stir Welding Process

"1. Demonstrate Virtual Manufacturing/AR/VR technology, integrate product design and process planning processes (simultaneous engineering).

2. 3D printing design system: Utillized Rhino’s built-in calculation editor Grasshopper and infinite element method to generate complex lattice microstructures. The lattices model could directly transfer to all types additive manufacturing machine to fabricate the designs, allowing for rapid prototyping and lattices shapes iteration.

3. The AI expert system for friction stir welding (FSW) manufacturing integrates the following technologies. The expert system will be trained using the AI machine learning. During the FSW manufacturing, the AI expert system of FSW will be applied to update the welding parameters to the controller after the AI decision adaptively.

1. Through the virtual processing analysis of the virtual HA500II four-axis machine tool and the CT350 five-axis machine tool, many product process and design problems can be observed with various viewpoints in the virtual simulation, effectively shortening the development cycle of new processes.

2. The big data prediction system and software developed by the 3D printing design system can fast calculate the mechanical properties and characteristics of the complex lattice design structure after the 3D printing process.

3. The welding history record also makes the product traceable. The life of welding tools can be predicted by accumulating enough data. The AI expert system of friction stir welding manufacturing can save substantial cost of production and management.

1. Virtual manufacturing can assist the manufacturing industry in product development and plant planning more efficiently.

2. The mechanical properties of the novel lattice design microstructure developed by 3D printing software can be used in robotics, aeronautics, biomedicine, sports protection and other fields.

3. The AI expert system for friction stir welding process can cover the shortage of technology and manpower, and optimize the welding parameters so as to speed up the application of the FSW process. The more recent application of FSW had penetrated into the semiconductor and private industry. Especially for the aluminum and copper light metal, the corresponding product has high additional value.

"

National Chung Cheng University is a national university in Minxiong Township, Chiayi County, Taiwan. CCU is a member of the Association to Advance Collegiate Schools of Business.

Name:高靖茵

Phone:(05)272-0411 ext. 16462

Address:No.168, Sec. 1, University Rd., Minhsiung, Chiayi 621301, Taiwan

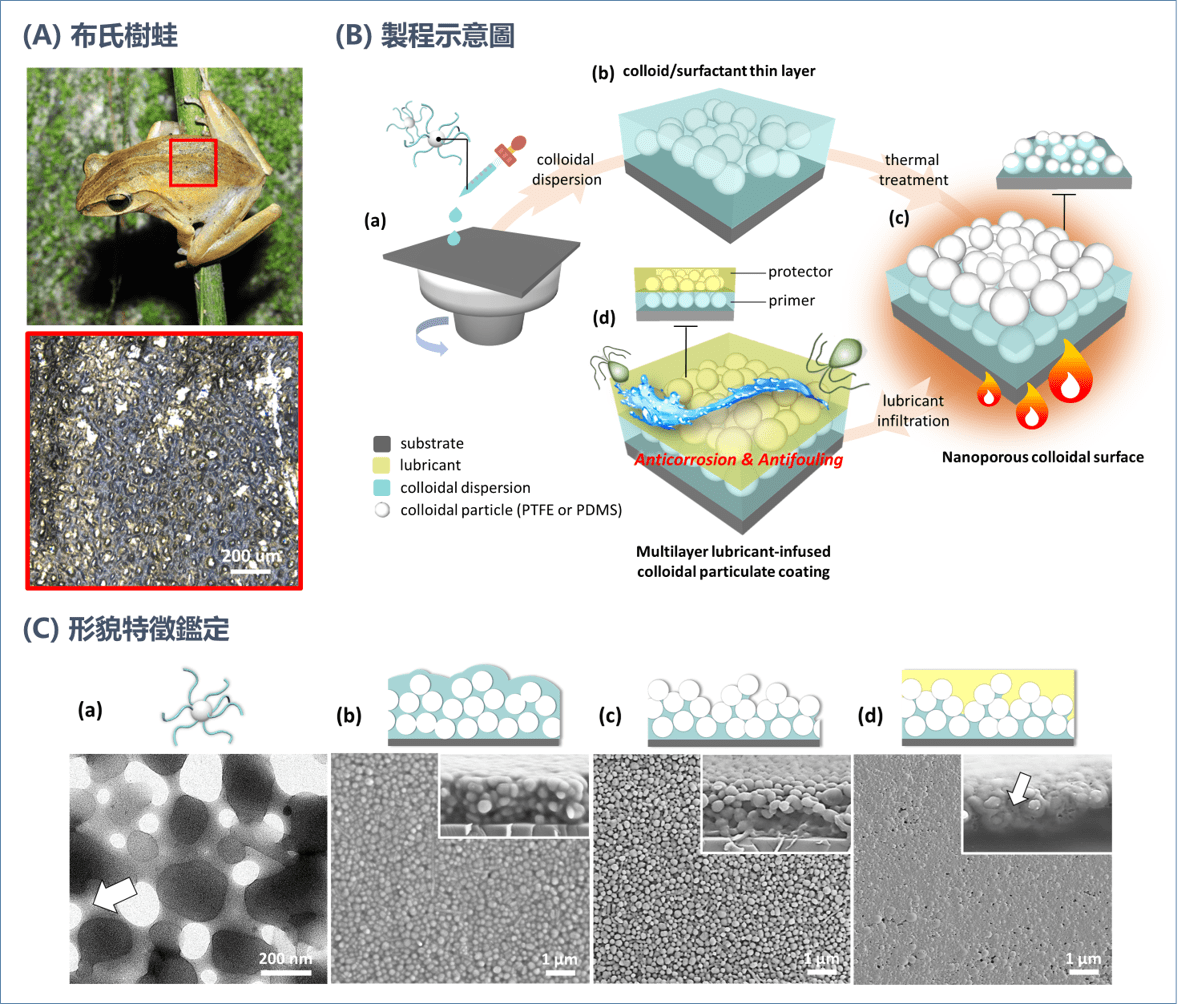

Amphibian-Inspired Lubricant-Infused Particulate Films as Slippery Protective Coatings with Durable Anticorrosion and Antifouling Performance

.png)

Green & Continuous Manufacturing, a novel integrated liquid-liquid micro-extractor and separator for rapid downstream process characterization.

Upcycled Waste PET-Based Technologies for Conductive Self-Healing Wearables, Dynamic Environmental Monitoring, and Photochromic Anti-Counterfeiting

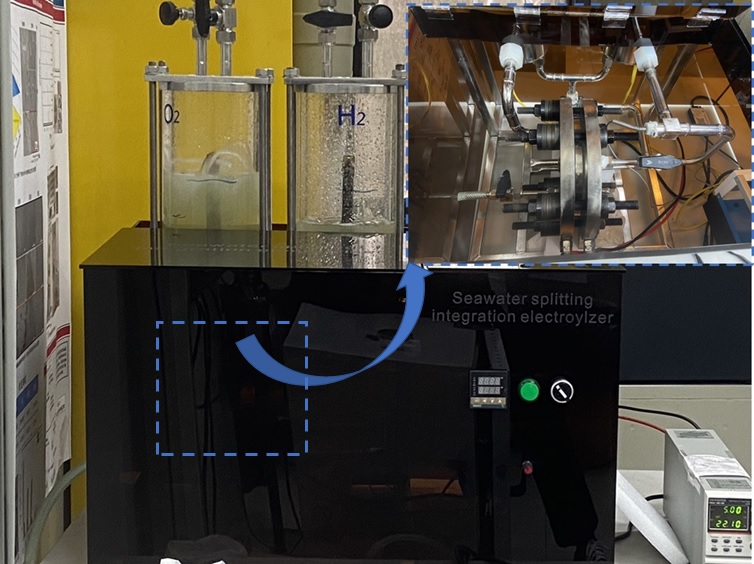

Comprehensive Research and Industrialization Development of High-Entropy Catalysts for Hydrogen Production from Seawater

Technology maturity:Experiment stage

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!