Green & Continuous Manufacturing, a novel integrated liquid-liquid micro-extractor and separator for rapid downstream process characterization.

.png)

.png)

This proposed technique aims for solving the key challenge in the chemical, pharmaceutical, and biomedical raw material industries: how to develop effective and economically feasible downstream processing. We presented an integrated continuous extraction and phase separation reactor, which consist of a unique helix wire to precisely control the liquid-liquid interface. It provides R&D and industry with a complete solution at production sites to quickly screen downstream processing with different permutations and combinations and greatly reduces time costs and expensive materials used.

The integrated continuous extraction and phase separation reactor consists of a unique helix wire structure that acts as a supporting structure at the aqueous–organic interface. The interface is anchored firmly and clearly for continuous compound extraction and the interfacial pressure is precisely controlled by the pitches of the elastic helix wire. This is the first integrated downstream processing reactor for continuous manufacturing with such a wide operational range and it provides a total solution for almost every aspect of overwhelming ordeals in continuous manufacturing.

The technique demonstrates prominent robustness, operability, flexibility, and simple operation compared with a bench-scale extraction continuous stirred-beaker reactor and other microreactors. It shows potential as a rapid screening tool for various two-phase extraction model systems. Information such as the optimization of raw material usage can be fed back to maximize the efficiency of production while reducing waste, energy and pollution during every manufacture. Thus pursuing the overarching goals of green chemistry and sustainable -production for the next generation.

線上展網址:

https://tievirtual.twtm.com.tw/iframe/4e128354-4782-407b-a23a-bca43eefa053?group=23bfb1fa-dd5b-4836-81a1-4a1809b1bae5&lang=en

National Chung Hsing University (NCHU), established in 1919, is located in Taichung, Taiwan. It is a comprehensive university offering a wide range of programs in agriculture, engineering, science, humanities, and social sciences. NCHU is known for its strong emphasis on research, innovation, and sustainability. With a focus on international collaboration and community engagement, the university strives to cultivate leaders with global perspectives. NCHU aims to contribute to society through high-quality education, advanced research, and fostering a diverse academic environment.

The innovative technology that turns waste into treasure – Silicon Dioxide regenerated from semiconductor waste that contains Silicon

Sustainable development of CO2: chemically converted to magnetic carbon nanofibers and their industrial applications

Key Technology for Advanced Industry 4.0: Advanced Intelligent Manufacturing Cell, 3D Printing Design Systems, AI Expert System for Friction Stir Welding Process

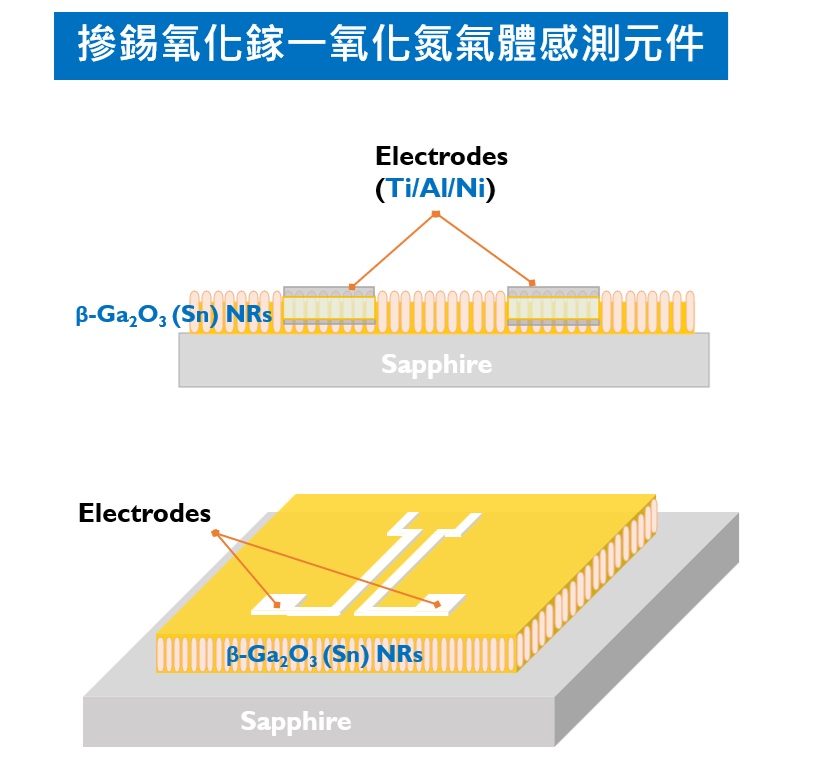

A novel high-performance Sn-doped gallium oxide thin-film nitric oxide gas sensor for applications in smart healthcare and environmental monitoring

Technology maturity:Prototype

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation、Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!