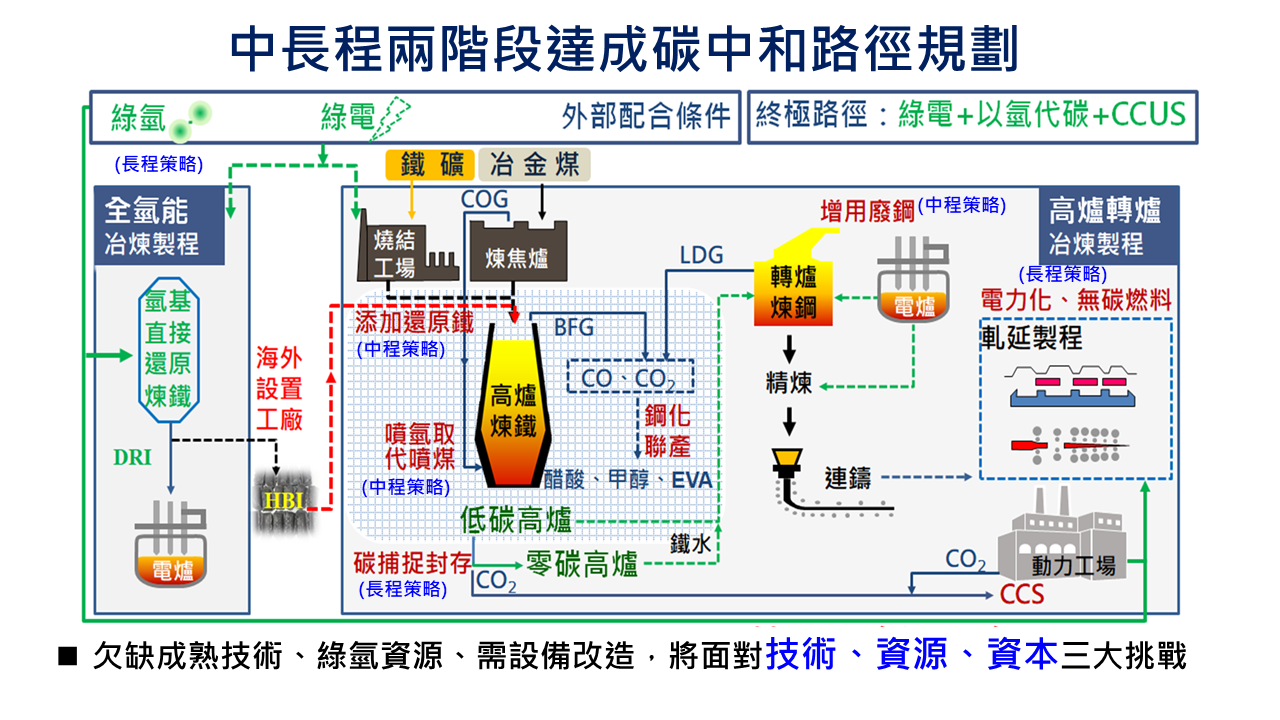

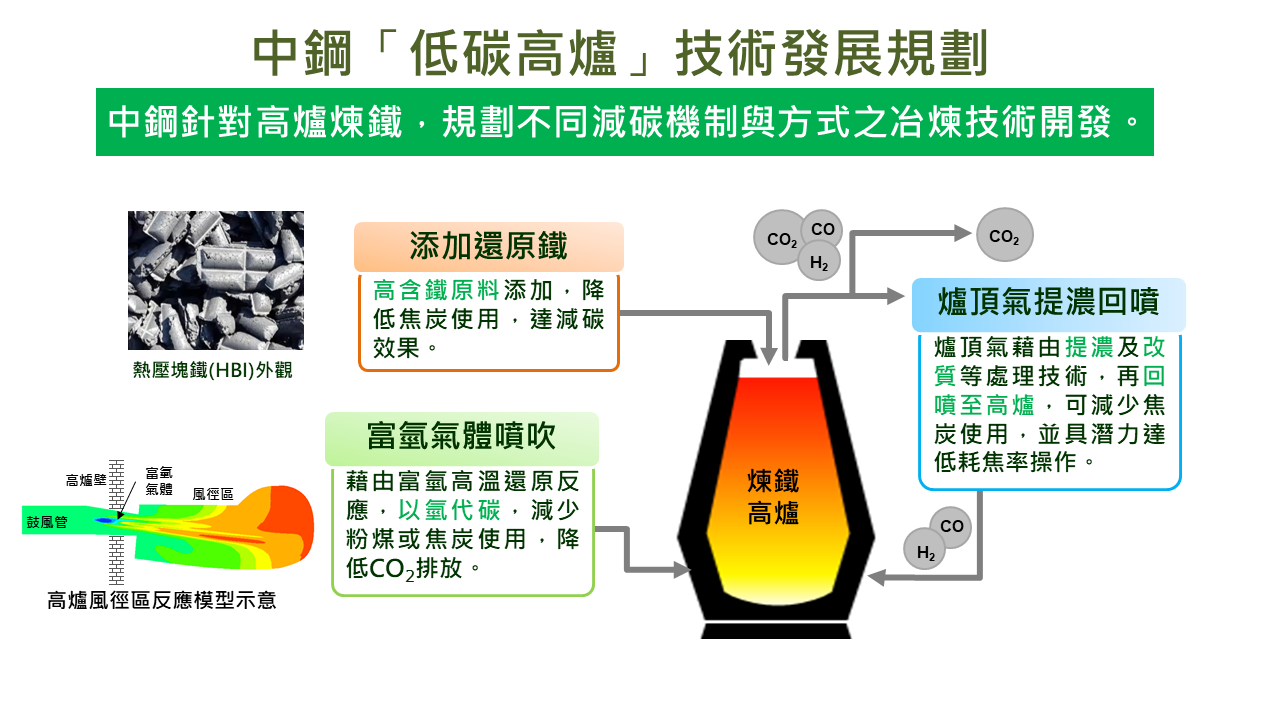

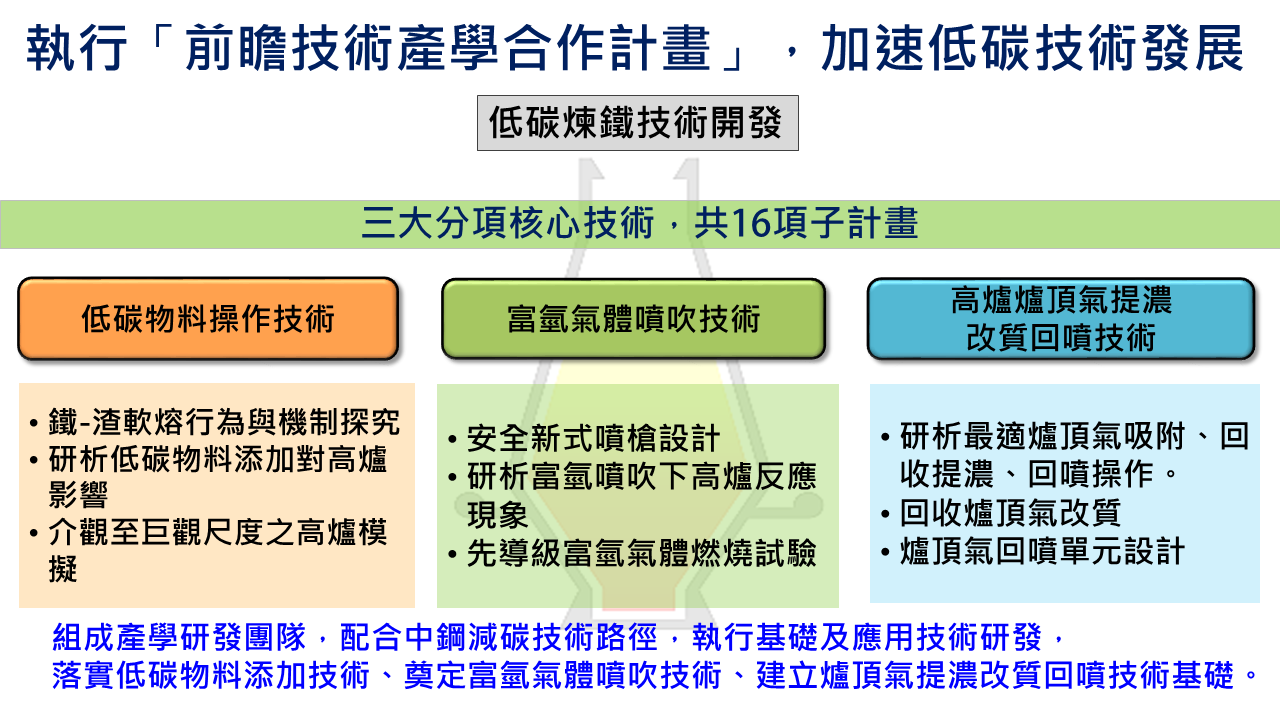

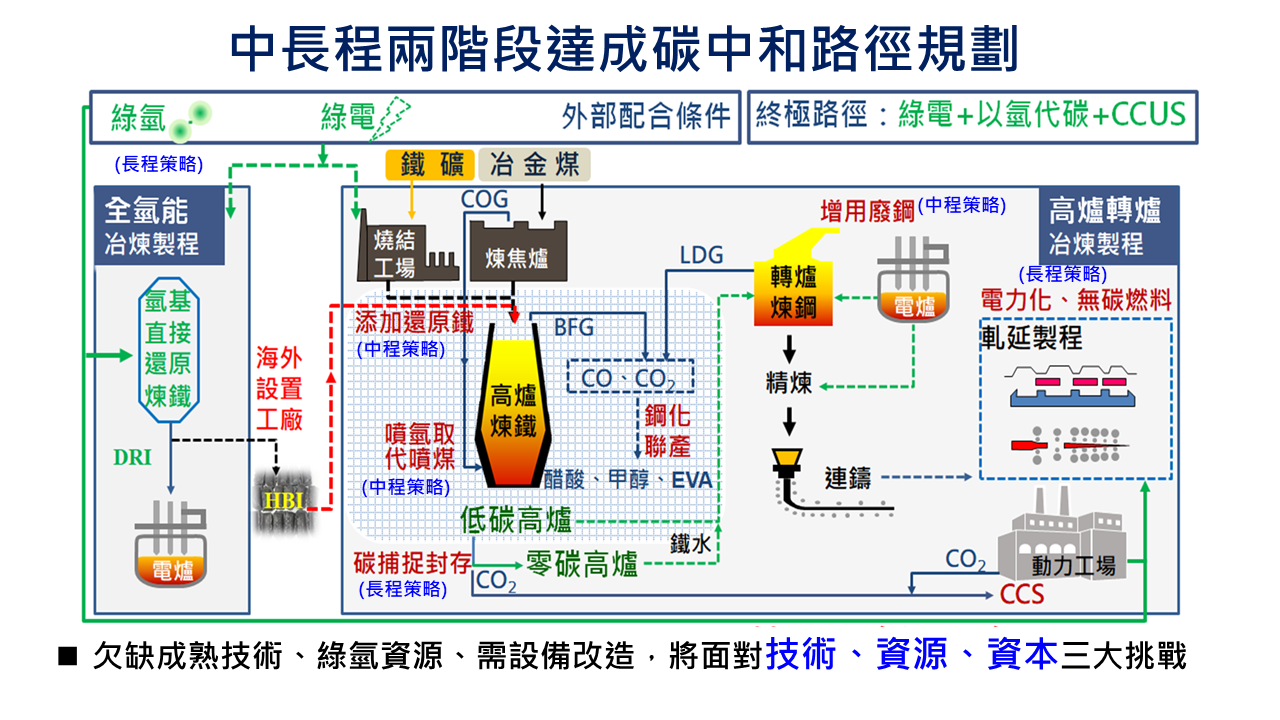

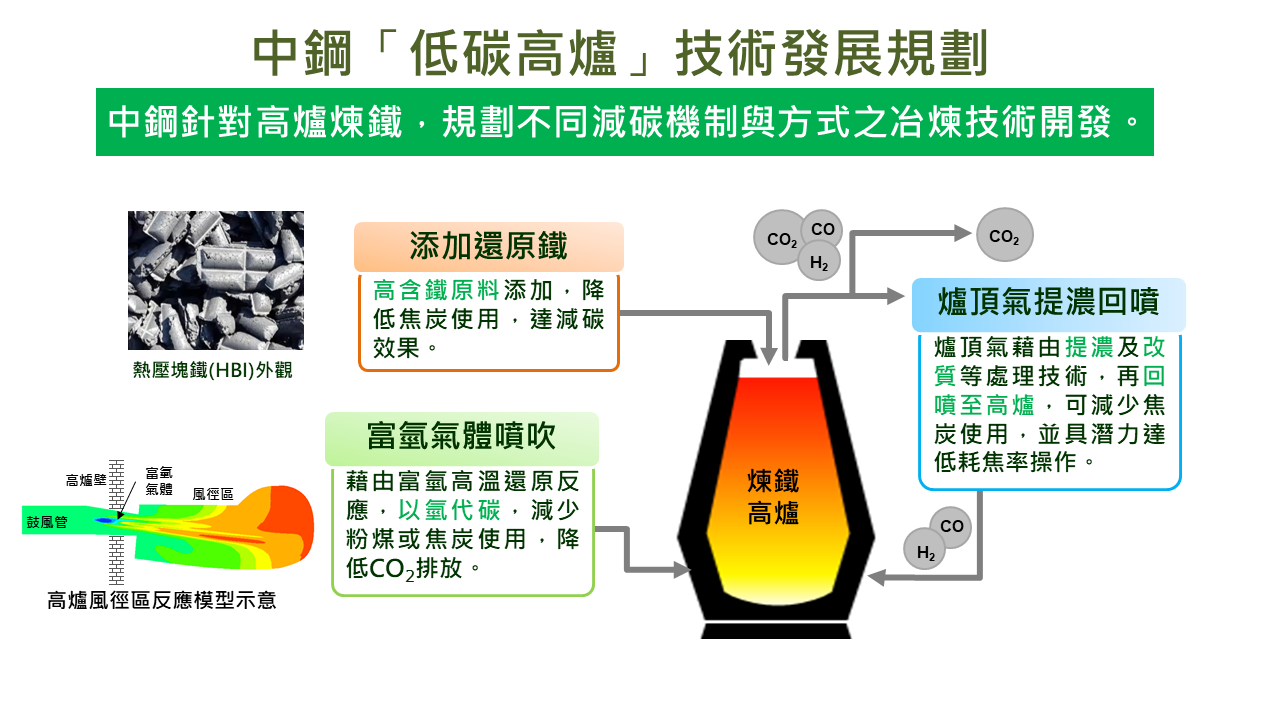

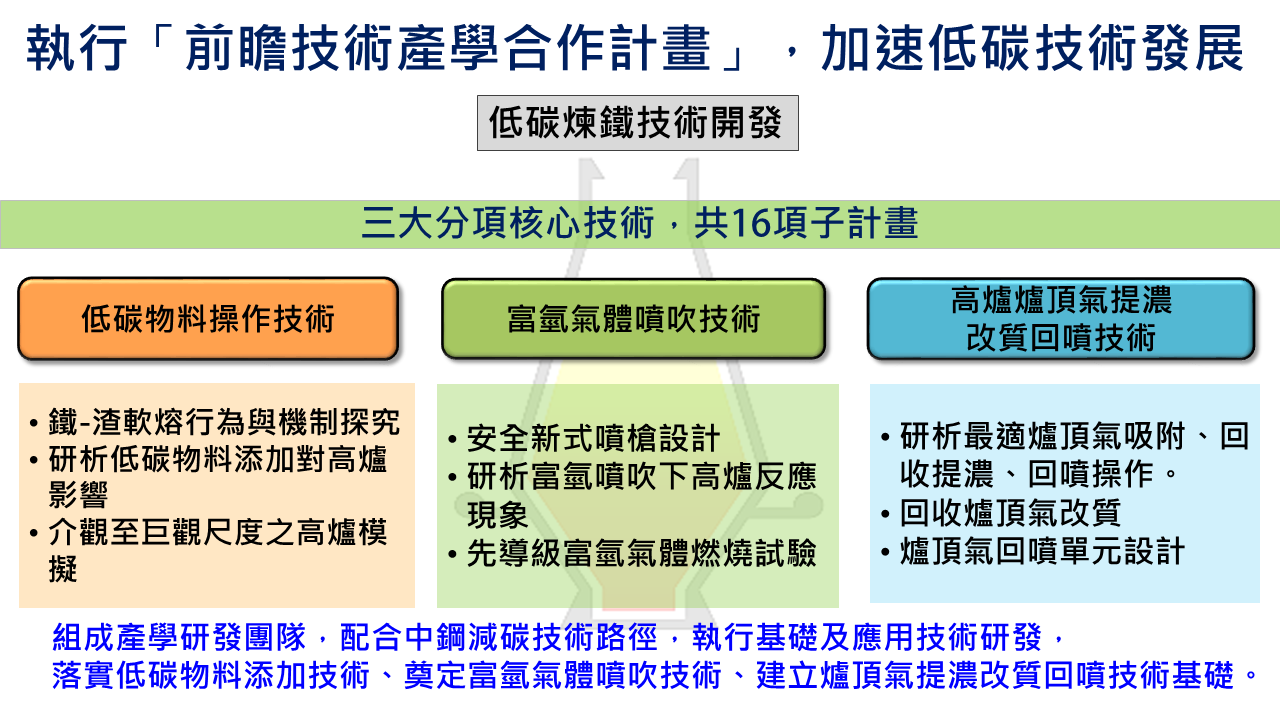

CSC mainly planned 3 technology cores in the development of low carbon blast furnace technologies, including (1) adding low carbon charge; (2) hydrogen-rich gas injection; (3) gas CO2 capture and modification, in which the first two items are short-term and mid-term implementation goals. For low carbon charge, the Company has successfully developed technology for adding reduced iron in blast furnace, and successfully added 150 kg of reduced iron pellets to each tonne of hot metal during testing. Due to the significant carbon reduction effects, 50 kg of reduced iron is regularly added to each tonne of hot metal at #3 blast furnace with consideration to the production volume of reduced iron. With regard to hydrogen-rich gas injection, the Company plans to inject hydrogen-rich COG into the blast furnace before it obtains green hydrogen, and will use hydrogen to replace coal to reduce carbon emissions from the blast furnace. CSC has referenced overseas cases and technologies and successfully designed a blast furnace simulator for multiple layers of high temperature materials during hydrogen-rich operations, which can be used to evaluate the reaction characteristics from the material surface to the dripping charge. The equipment completed cold and hot commissioning at the foreign equipment manufacturer's plant before shipment in October 2022, and system installation has completed. It is worth noting that CSC utilizes the capabilities of academia by jointly forming a research team, and submitted an application to the NSTC for the development of low carbon blast furnace technology. The application was approved by the NSTC as an Advanced Technology Industry-Academia Collaboration Project, and was implemented in November 2022 with the 3 core technologies described above, engaging in 16 research projects.

China Steel Corporation (CSC), located in Kaohsiung City, was founded in December 1971. With annual crude steel production of 10 million metric tonnes, CSC’s main products include plates, bars, wire rods, hot and cold rolled coils, electrogalvanized coils, electrical steel coils, and hot-dip galvanized coils. The domestic market takes roughly 58.9% of CSC’s production and the exports take the remaining 41.1%. CSC is the largest steel company in Taiwan with market share of more than 50% and export products mainly to Southeast Asia, Europe and Japan.

Name:

Phone:0912162024

Address:1, Chung Kang Rd., Hsiao Kang, Kaohsiung 81233, Taiwan, Republic of China

Engineering Technology Development for Bottom Fixed Underwater Structures of Offshore Wind Turbines under Extreme Environments

Sustainable development of CO2: CO2 chemically converted to magnetic carbon nanofibers and their environment and biomedical applications

Development of Synergistic Thermophilic Anaerobic Co-Digestion Technology with High Ammonia Tolerance

Development of a New Generation of Hydrogen Storage Tanks - Ultra-Thin Thermoplastic Winding Tape Process Technology

Technology maturity:Trial production

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!