Development of Synergistic Thermophilic Anaerobic Co-Digestion Technology with High Ammonia Tolerance

Data from the Taiwan Agriculture and Food Agency shows that in 2012, Taiwan used 1.01 million tons of chemical fertilizers, approximately 1.6 times the international average. Organic fertilizers are a more environmentally friendly choice but traditional production methods are energy-intensive and have high carbon emissions. This technology utilizes innovative thermophilic anaerobic ammonia-tolerant microbial consortia to break through the limitation of molecular ammonia on anaerobic reactions and to reuse resources. Converts carbon dioxide and hydrogen to 90% methane concentration and allows organic matter to decompose more quickly to a stable state. The composition of organic fertilizers can be adjusted according to different needs, reducing production costs and energy consumption. By using anaerobic microbial consortia modification technology achieving green energy production and organic resources utilization and reaching circular economy. This innovative technology not only improves the efficiency of organic fertilizer production but also makes agriculture more environmentally friendly and sustainable.

ITRI is a world-leading applied technology research institute with more than 6,000 outstanding employees. Its mission is to drive industrial development, create economic value, and enhance social well-being through technology R&D. Founded in 1973, it pioneered in IC development and started to nurture new tech ventures and deliver its R&D results to industries. ITRI has set up and incubated companies such as TSMC, UMC, Taiwan Mask Corp., Epistar Corp., Mirle Automation Corp., and Taiwan Biomaterial Co.

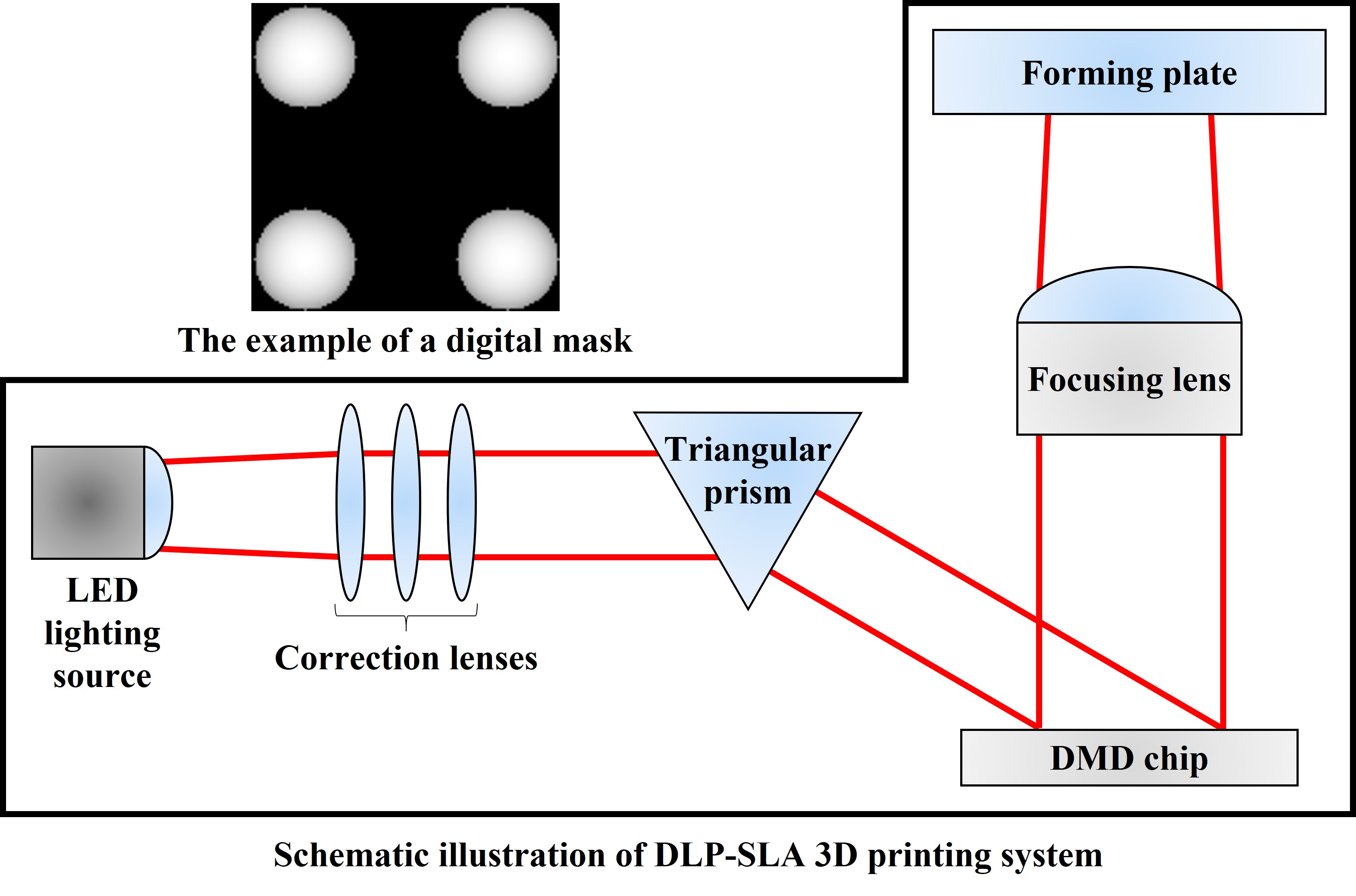

Integrating Digital Grayscale, Defocus Method and Newly Developed Pho topolymer to Stereolithography 3D Printing Process to Rapidly Manufact ure Microlens Array with High Optical Performance

Value-Added Smart Environmental-Friendly Real-Time Meat Freshness In dicator for Meat Products- Value-Added Technology of Agricultural Waste

Development of a New Generation of Hydrogen Storage Tanks - Ultra-Thin Thermoplastic Winding Tape Process Technology

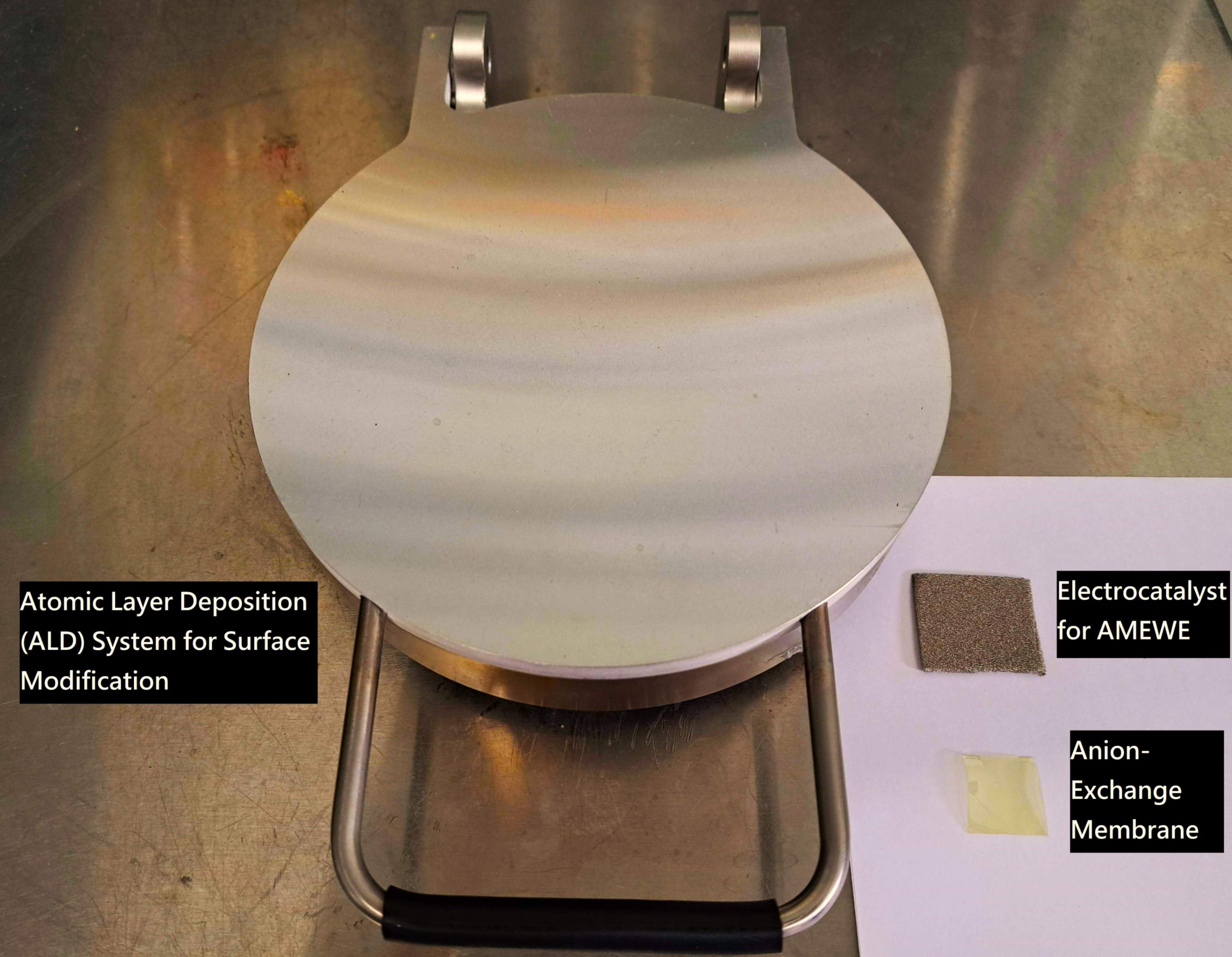

High practicality surface modification technology for enhancing hydrogen production via water electrolysis and solid-state hydrogen storage efficiency

Technology maturity:Trial production

Exhibiting purpose:Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!