Integrating Digital Grayscale, Defocus Method and Newly Developed Pho topolymer to Stereolithography 3D Printing Process to Rapidly Manufact ure Microlens Array with High Optical Performance

Microlens arrays (MLAs) have been widely applied. Currently, the fabricati

on of MLAs involves precise machining and photolithography, which suffe

r from high equipment costs, long production times and large amount of

wastes, and they also impose significant limitations on the shape of microl

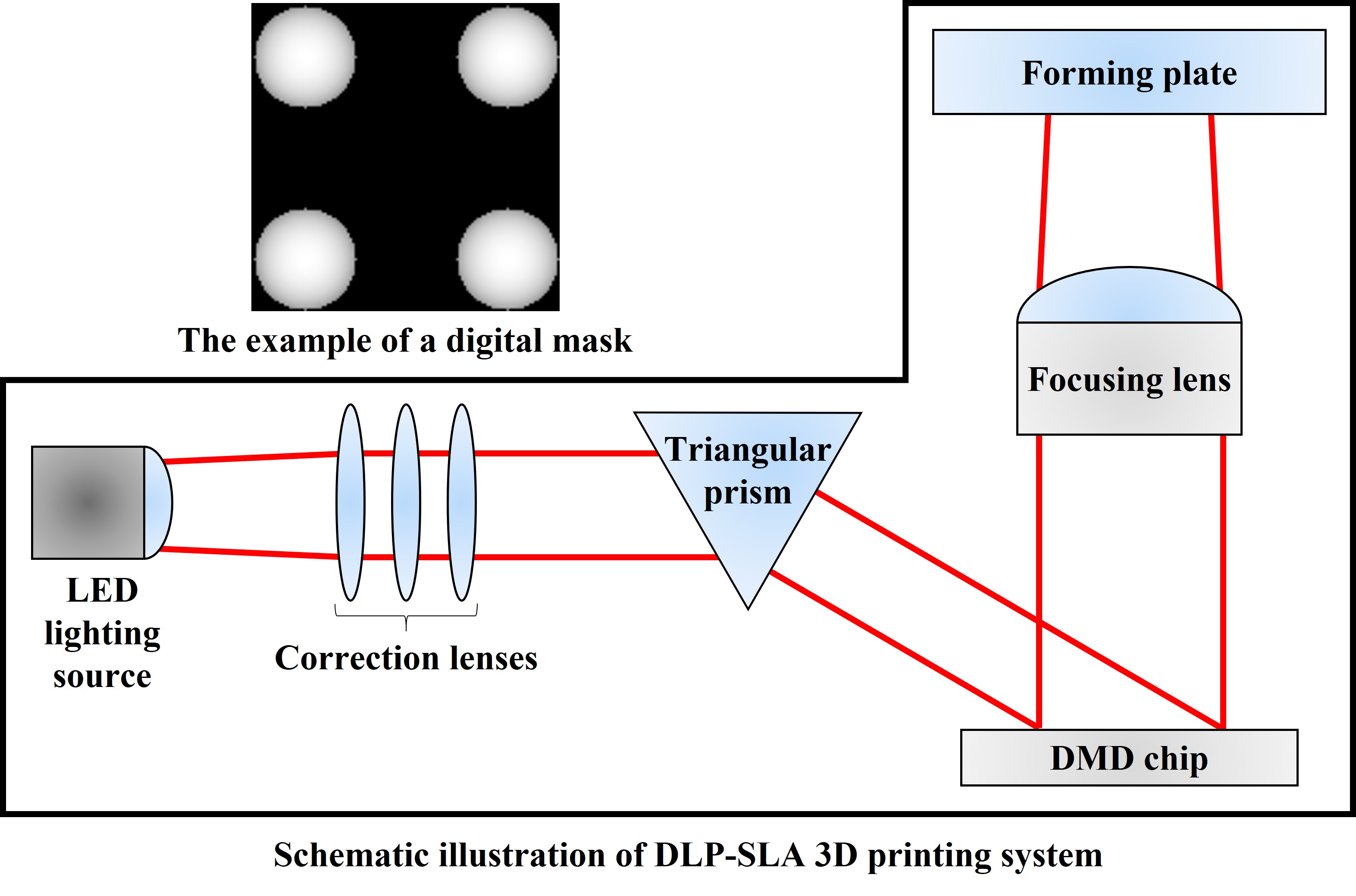

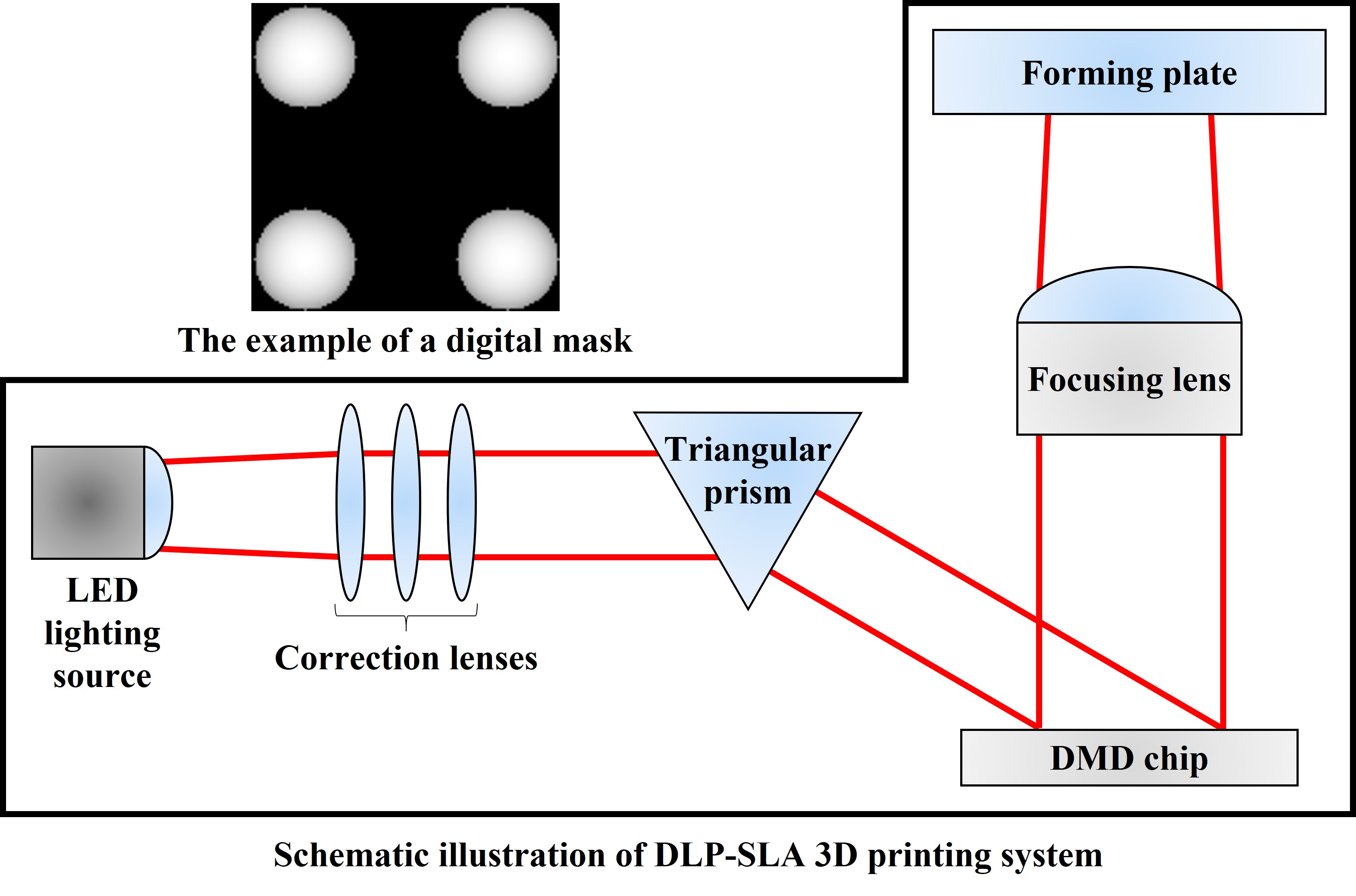

enses. Digital light processing (DLP) 3D printing technology offers advant

ages such as low cost, shorter production time and being more environme

ntally friendly. However, the surface roughness of MLAs produced by DLP

3D printing technology is difficult to meet the requirements of optical co

mponents due to stair effect.

Our team employed adjustable grayscale masks in the manufacturing pro

cess. By adjusting the imaging position of the digital mask and the distanc

e between the mask and the forming platform, we create a defocus metho

d to eliminate stair effect and enabling the surface roughness of the micro

lens array to meet the requirements of optical components. Compared to

traditional processes, our technology can achieve MLA shapes that were p

reviously unattainable. In addition to the aforementioned manufacturing

method, our team has also utilized newly developed photopolymer specifi

cally designed for optical components. The goal is to enhance the resoluti

on, numerical aperture, and size limits of the micro lens array, thereby gre

atly expanding its range of applications.

It takes 1 second to solidify the polymer, and the entire fabrication proces

s takes 15 minutes. The resulting surface roughness is below 50 nm, while

the lens resolution can reach 58.7 lp/mm, which is more than that of com

mercial MLAs (resolution ~ 55 lp/mm). The diameter of the microlens is as

small as 60 μm. It is possible for us to fabricate microlens with high numer

ical apertures (0.98), multiple focal lengths (20 μm to 200 μm), and high fil

l factor (77.98%). The MLAs in this study can be applied to image panels a

nd sensors, and their optical performance are on par with commercial cou

nterp

Taiwan Tech has five campuses: the main Taipei campus and branch campuses at Tu-Cheng, Keelung, Gong-Guan, and Chupei, with a combined total area of 29.44 hectares. The main campus, situated in a district of Taipei with convenient transportation and beautiful surroundings, covers an area of about 10 hectares. Current enrollment includes 5,605 undergraduates and 4,902 graduate students with 415 full-time faculties.

Green adsorption materials and energy-saving exhaust gas treatment equipment used in the treatment of industrial volatile organic compounds

Single-Stage Electronic Lighting Driver for LED Streetlight Applications with Features of High-Power-Factor and Soft-Switching

Integrated Method for Improving Production Rate of Biogas Using Lignocellu-losic Depolymerization with Anaerobic Digestion

The design development technology and Power Generation system of Organic Rankine Cycle and Trans-critical Organic Rankine Cycle for Conversion of Low-and-Medium Heat.

Technology maturity:Experiment stage

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!