Machine Tool and Processing Technology Development for Direct Energy Deposition Method in Metal 3D Printing

Technologies are developed for high quality DED aerospace and mechanical parts. There are two parts:

(1)Machine tool development is achieved through integrating the control of a 5-axis machine tool and a 3 kW continuous high power fiber laser. Human-machine interface is also developed. Powder delivery system and laser head are also considered.

(2)Processing technology development is achieved via optimizing process parameters such as laser power, powder feed rate, laser scanning speed etc. and fabrication path of the process through CAM software to obtain the best quality parts. Optimized Process-structure-properties relationship is available for SUS316 and Inconel 718 materials.

By integrate these two technologies, DED parts with good quality can be made.Technologies are developed for high quality DED aerospace and mechanical parts. There are two parts:

(1)Machine tool development is achieved through integrating the control of a 5-axis machine tool and a 3 kW continuous high power fiber laser. Human-machine interface is also developed. Powder delivery system and laser head are also considered. This feature makes this technology easy to be used.

(2)Processing technology development is achieved via optimizing process parameters such as laser power, powder feed rate, laser scanning speed etc. and fabrication path of the process through CAM software to obtain the best quality parts. This technology makes the quality of DED parts excellent.

By integrate these two technologies, DED parts with good quality can be made and cost effective.Technologies are developed for high quality DED aerospace and mechanical parts.

(1)Machine tool development is achieved through integrating the control of a 5-axis machine tool and a 3 kW continuous high power fiber laser. Human-machine interface is also developed.

(2)Processing technology development is achieved via optimizing process parameters such as laser power, powder feed rate, laser scanning speed etc. and fabrication path of the process through CAM to obtain the best quality parts. Optimized Process-structure-properties relationship is available for SUS316 and Inconel 718 materials.

By integrating these two technologies, DED parts with good quality can be made. DED is suitable for applications such as big material removal process, new material development and complex parts.

The Engineering and Technology Promotion Center (ETPC) has been established in 1965 at National Cheng Kung University. It is the exclusive unit continuously supported by the Department of Engineering and Technologies, National Science and Technology Council under projects. The main missions of ETPC are to integrate and promote the academic research achievements, especially in engineering areas to the industry, and to upgrade/add the values of technologies in production development. This center plays an important role as a “bridge” between the academia and industry. In ETPC, an "eTop-Engineering and Technology Open Promotion platform" (www.etop.org.tw) has been established and managed online since 2011. In which, the reports of research projects supported by the Department of Engineering and Technologies, has been digital archived for reference since 2005.

Nano-Dimensional Self-Healing Technique and The Development for Elastic and Self-Healing Polymer Semiconductor

The new material and application technology of weather-resistant and anti-corrosion solar photovoltaics frame in coastal field

The Engine for Novel Chemical Engineering Process Development: a Fully Automated Platform for Comprehensive Physical Property Prediction

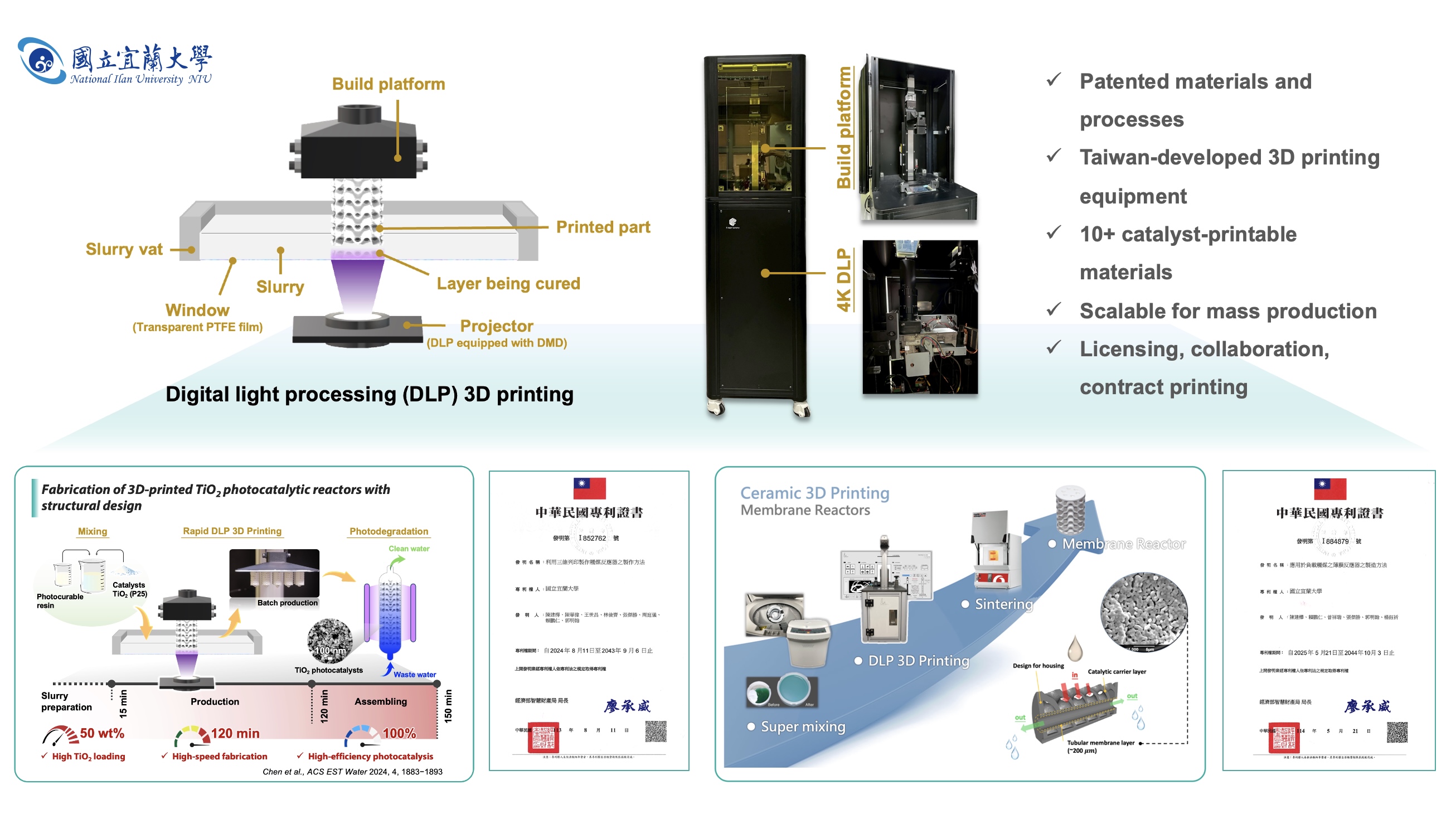

Scalable Catalytic 3D Printing Process Development: Enabling Smart Transformation in Chemical Reactor Bed Design and Manufacturing

Technology maturity:Prototype

Exhibiting purpose:Technology transactions、Product promotion、Display of scientific results

Trading preferences:Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!