The closed-loop immune cell manufacturing platform features enclosed chambers with temperature, humidity, and gas concentration control, providing the necessary growth environment for immune cells while reducing the risk of contamination. Key processes in immune cell manufacturing, such as cell activation, transduction, bead removal, and cell expansion, are modularized to flexibly adapt to production processes, addressing limitations of existing automated enclosed systems for cell production on the market.

ITRI is a world-leading applied technology research institute with more than 6,000 outstanding employees. Its mission is to drive industrial development, create economic value, and enhance social well-being through technology R&D. Founded in 1973, it pioneered in IC development and started to nurture new tech ventures and deliver its R&D results to industries. ITRI has set up and incubated companies such as TSMC, UMC, Taiwan Mask Corp., Epistar Corp., Mirle Automation Corp., and Taiwan Biomaterial Co.

Name:

Phone:

Address:195, Sec. 4, Chung Hsing Rd., Chutung, Hsinchu, Taiwan 31040, R.O.C.

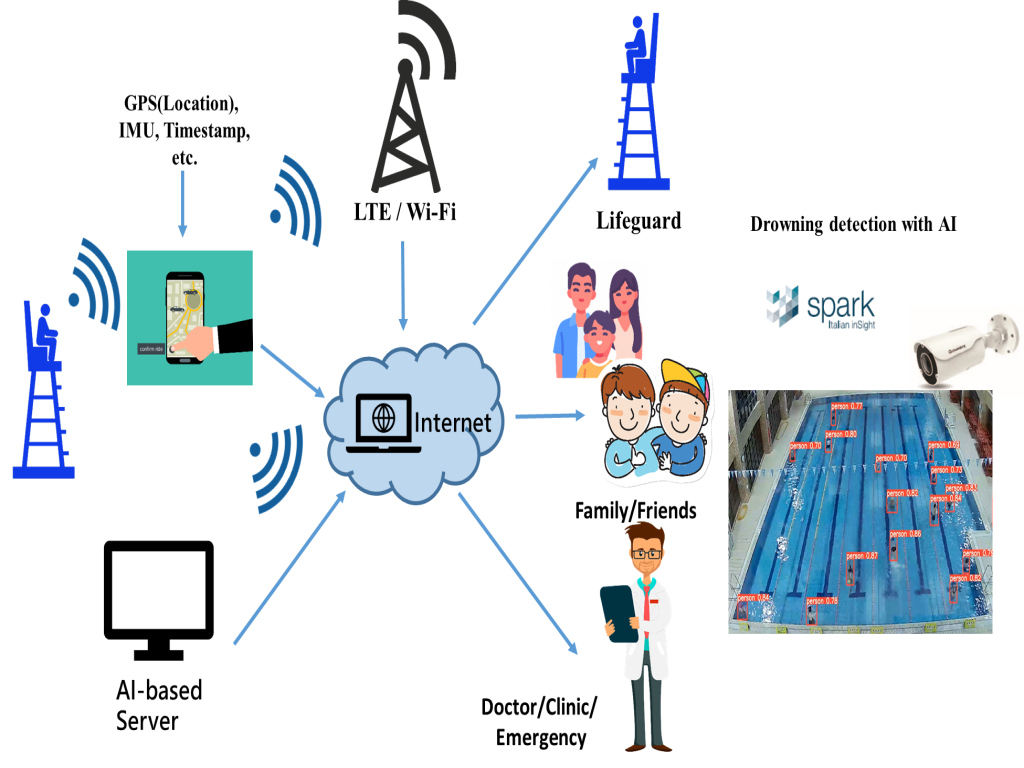

Automated and Intelligent System for Monitoring Swimming Pool Safety Based on the Edge AI Technique

Heterogeneous Multi-material Micro Additive Manufacturing for Electronic Devices

Lipid-Nanoparticles for RNA-based In-Vivo Applications or Ex-Vivo Immune Cell Modifications

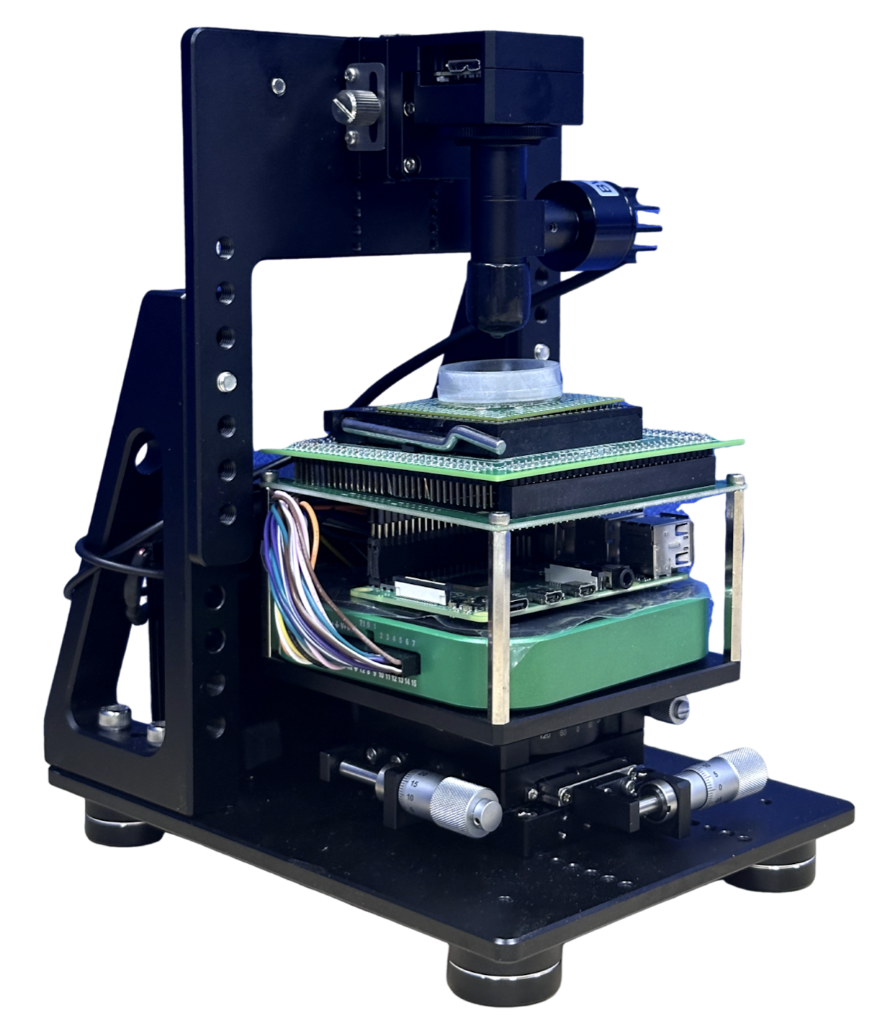

ProDEP: An Automated Platform for Precise Single-Cell Manipulation

Technology maturity:Prototype

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation、New products development

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!