Heterogeneous Multi-material Micro Additive Manufacturing for Electronic Devices

"Form patterned metal patterns in micro-multi-material additive manufacturing to directly integrate the manufacturing of metal-plastic hybrid micro-architectures. It produces highly complex devices with special functions by manipulating the manufacture of multiple inks and metal patterns.

Usage includes:

∙3D Functional Electronics (sensors, actuators, complex circuits)

∙Functional electrode (3D lattice structure plastic/metal composite)

∙3D Electronic Devices (Integrated battery, smart material/metal composite structure)

∙Complex shaped jewellery with brilliant metallic luster"

A research-intensive public university, Nanyang Technological University, Singapore (NTU Singapore) has 35,000 undergraduate and postgraduate students in the Business, Computing & Data Science, Engineering, Humanities, Arts, & Social Sciences, Medicine, Science, and Graduate colleges. NTU is also home to world-renowned autonomous institutes – the National Institute of Education, S Rajaratnam School of International Studies and Singapore Centre for Environmental Life Sciences Engineering – and various leading research centres such as the Earth Observatory of Singapore, Nanyang Environment & Water Research Institute and Energy Research Institute @ NTU (ERI@N).

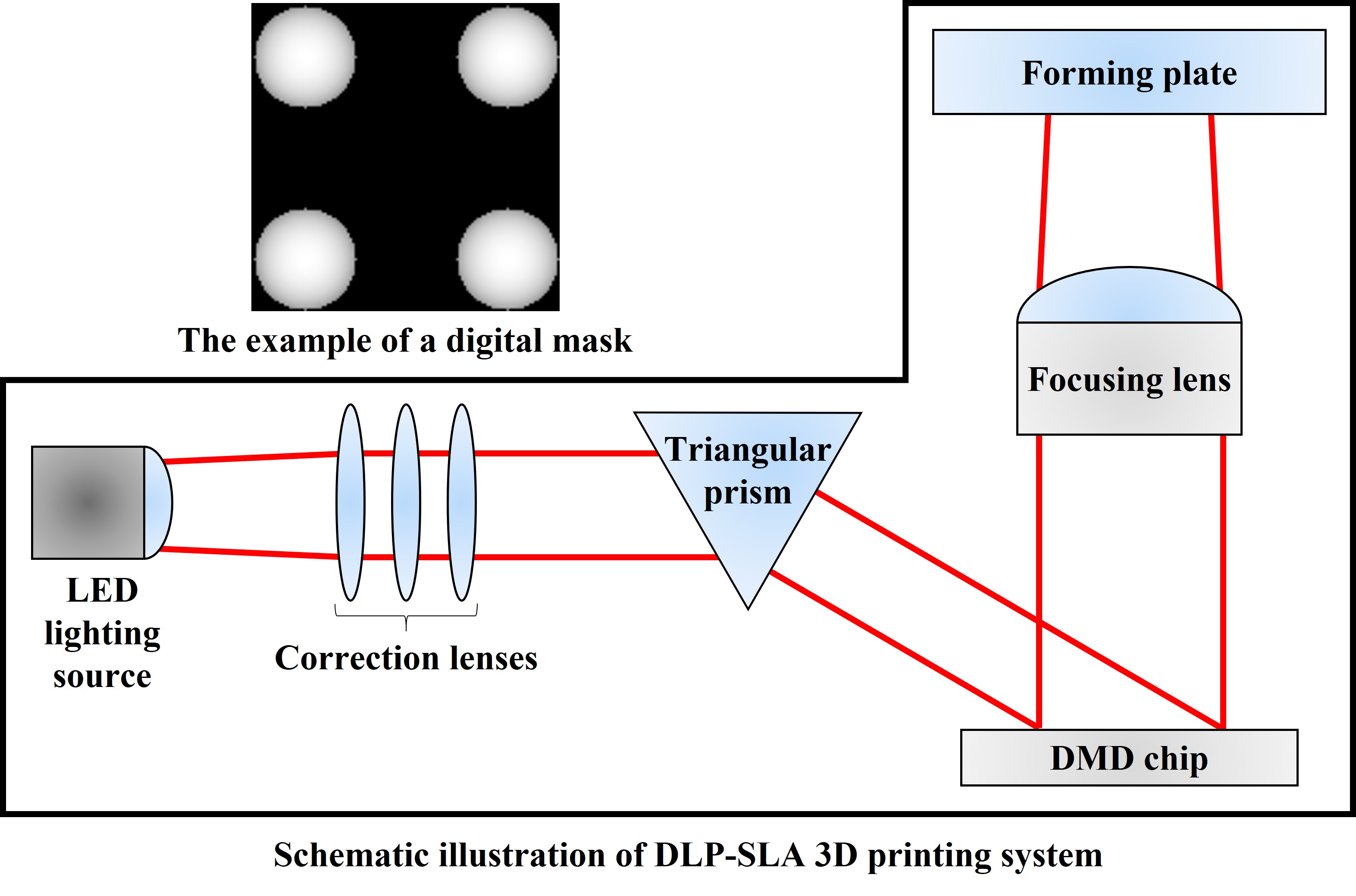

Integrating Digital Grayscale, Defocus Method and Newly Developed Pho topolymer to Stereolithography 3D Printing Process to Rapidly Manufact ure Microlens Array with High Optical Performance

Atmospheric Pressure Laser Coupling Multiphase Reactive Fluid Green 3D Nano/Micro Direct Synthesis and Patterning Technology

Metallic multi-material components deposition by additive manufacturing.

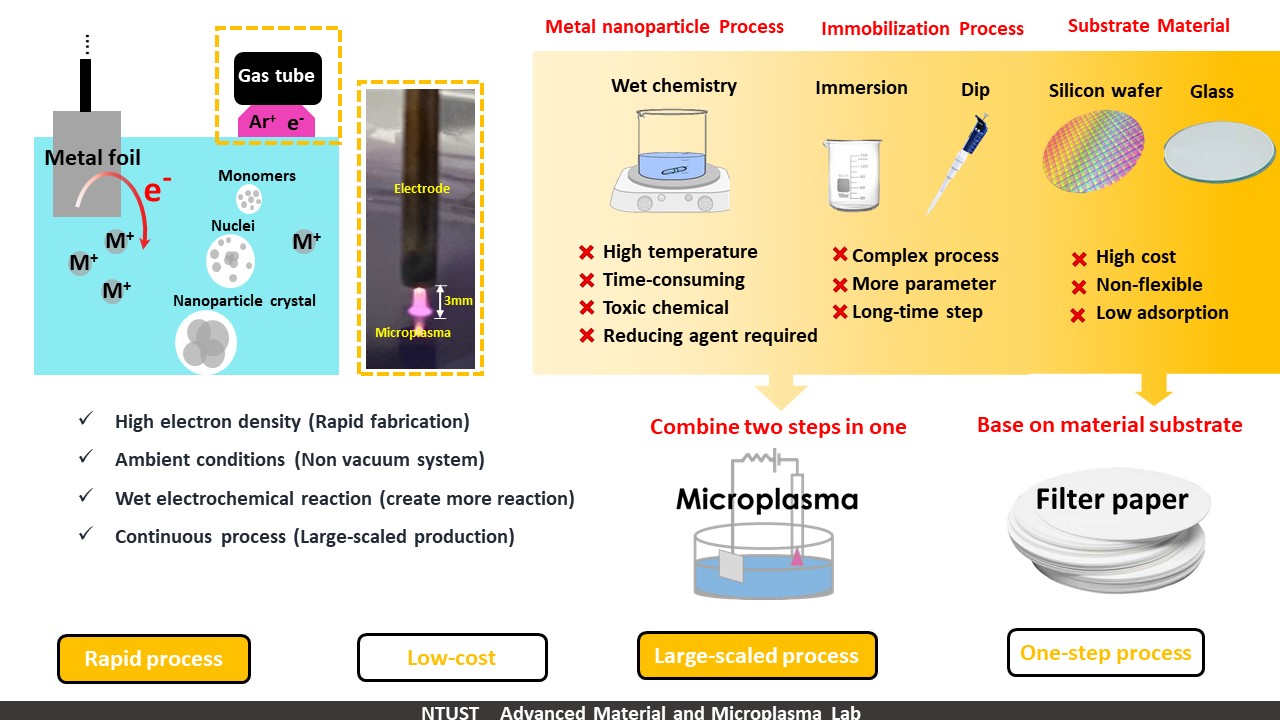

Three dimension nanoporous nanomaterial Microplasma-Enginnered assemblies on paper substrate for hydrogen gas production , surface-enhanced Raman scattering and catalytic reduction

Technology maturity:Others

Exhibiting purpose:Technology transactions、Product promotion

Trading preferences:New products development

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!