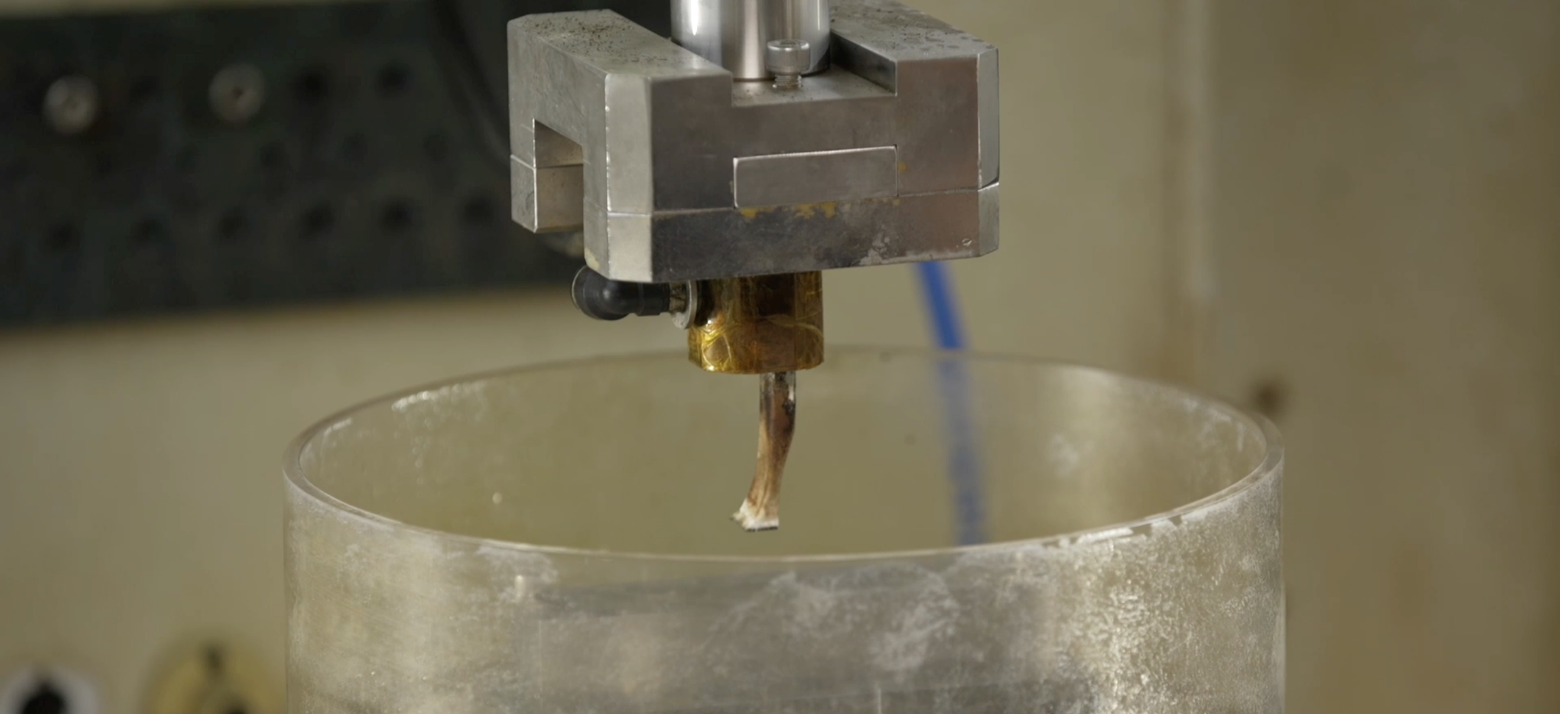

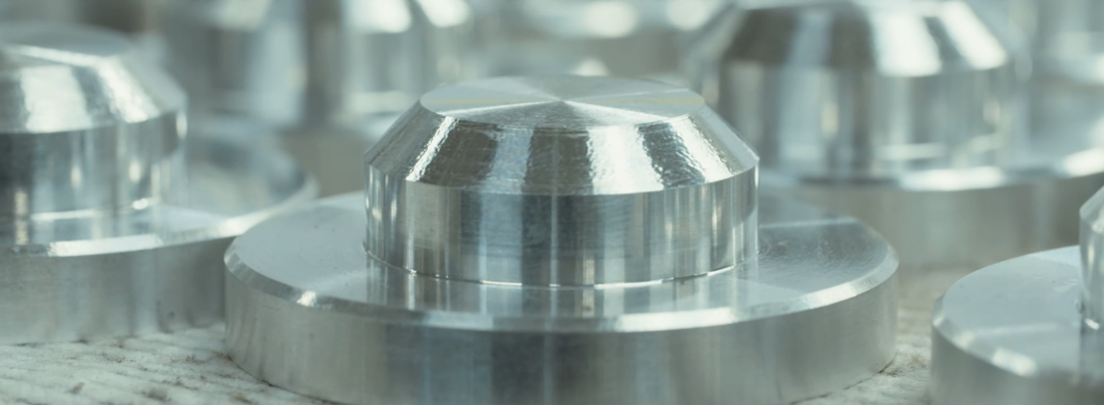

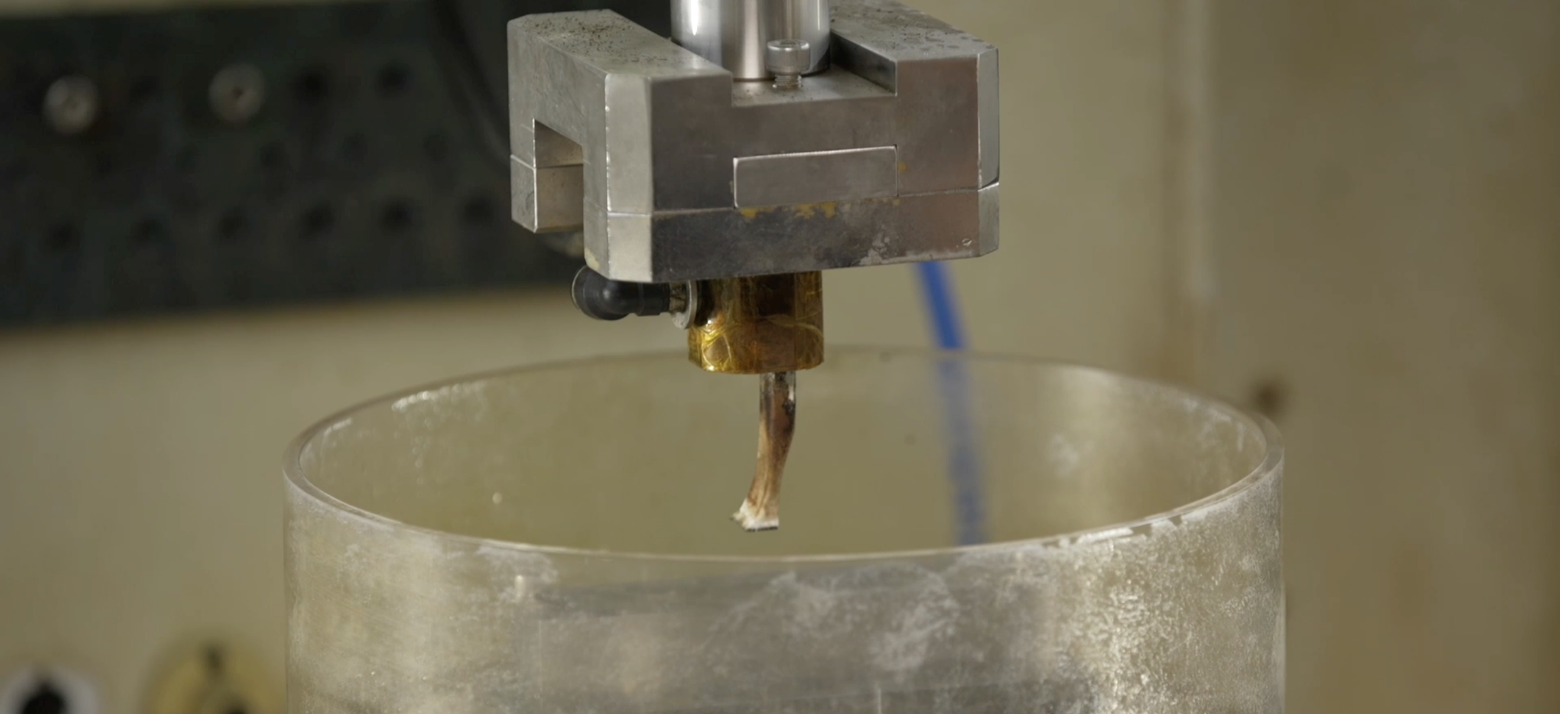

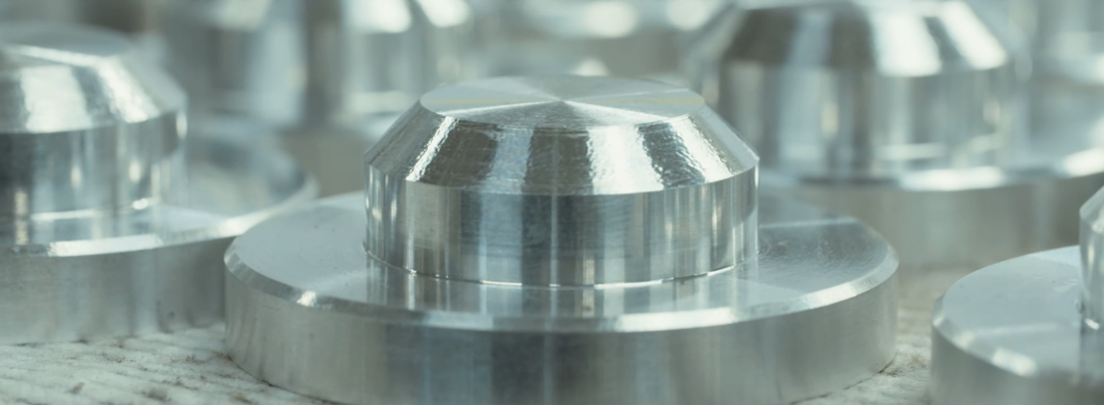

The HFECM retains various advantages of traditional ECM , such as no stress to be produced, not affected by material hardness, no burrs. The HFECM even brings the feature of NC machining freedom into full play to use simple profile and few numbers of working electrodes in completing the machining of complicated structure or structural part with curvature. In line with planning of manufacturing parameters predicting model, the HFECM can carry out machining compensation among passes to effectively reduce the number of machining passes, increase free-forming efficiency of ECM , provide a new innovative solution of rapid machining of difficult-to-machine metal materials and small quantity customized production model.

MIRDC (Metal Industries Research and Development Centre) continues to assist in industrial upgrading and transformation in response to policy development and the trend of the times, with five major industries, including metal material & fabricated metal products industries, high value-added precision micro manufacturing, green energy, high value equipment and medical devices & healthcare, as the core development, proactively promotes technical innovation and high-value applications. The Centre has not only strengthened the link between domestic and foreign technology R&D and the integration of talent and resources, but also established a cross-discipline R&D ecosystem. MIRDC has become a globally recognized R&D institute focusing on value-added activities for metal related industries.

Name:

Phone:07-3513121#2360

Address:No. 1001 Gaonan Road, Nanxun District, Kaohsiung City

The Intelligent Cloud Platform for the Machinery Industry and on-premise Taiwan Machinery Standard Runtime networking technologies.

High Free-forming Intelligent Electro Chemical Machining System Equipment (HFECM)

Application of Advanced Intelligent Feature Capture for Machine Tool Cutting States Monitoring and Prediction

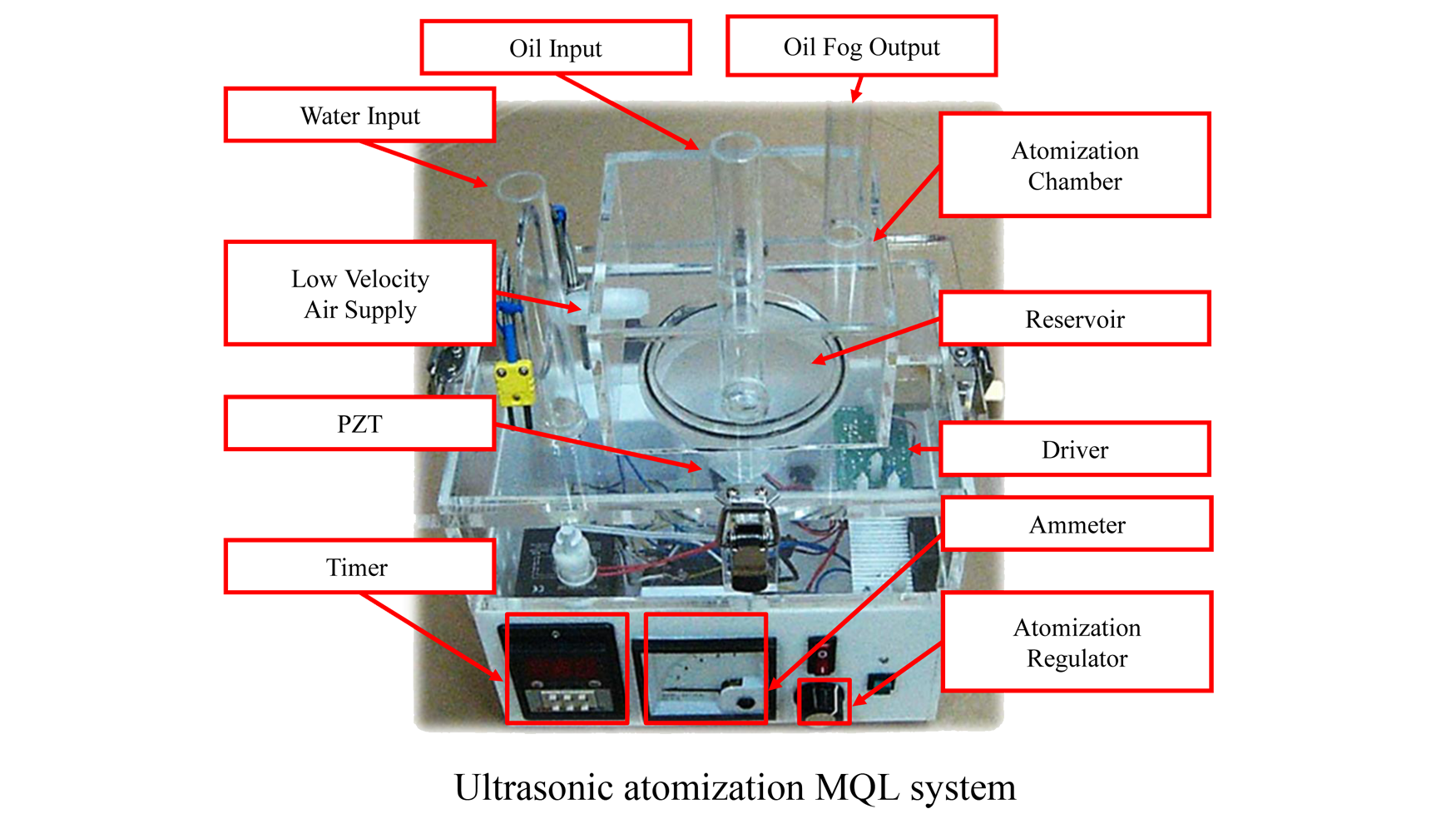

Nanofluid/ultrasonic atomization micro-lubrication system development and application intelligent modeling method to improve the multiple quality characteristics of the micro-machining process research and optimal prediction model establishment

Technology maturity:Mass production

Exhibiting purpose:Technology transactions

Trading preferences:Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!