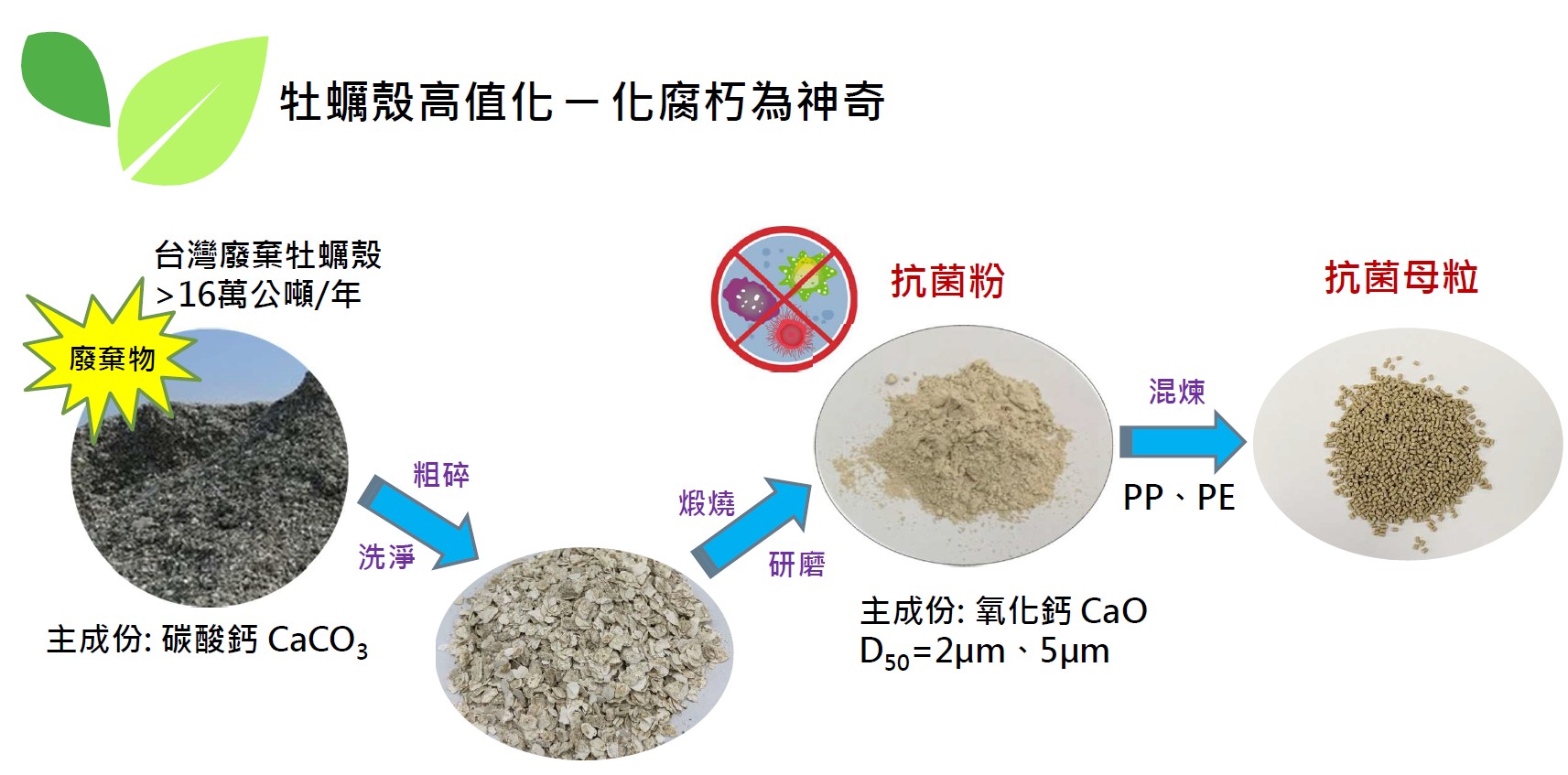

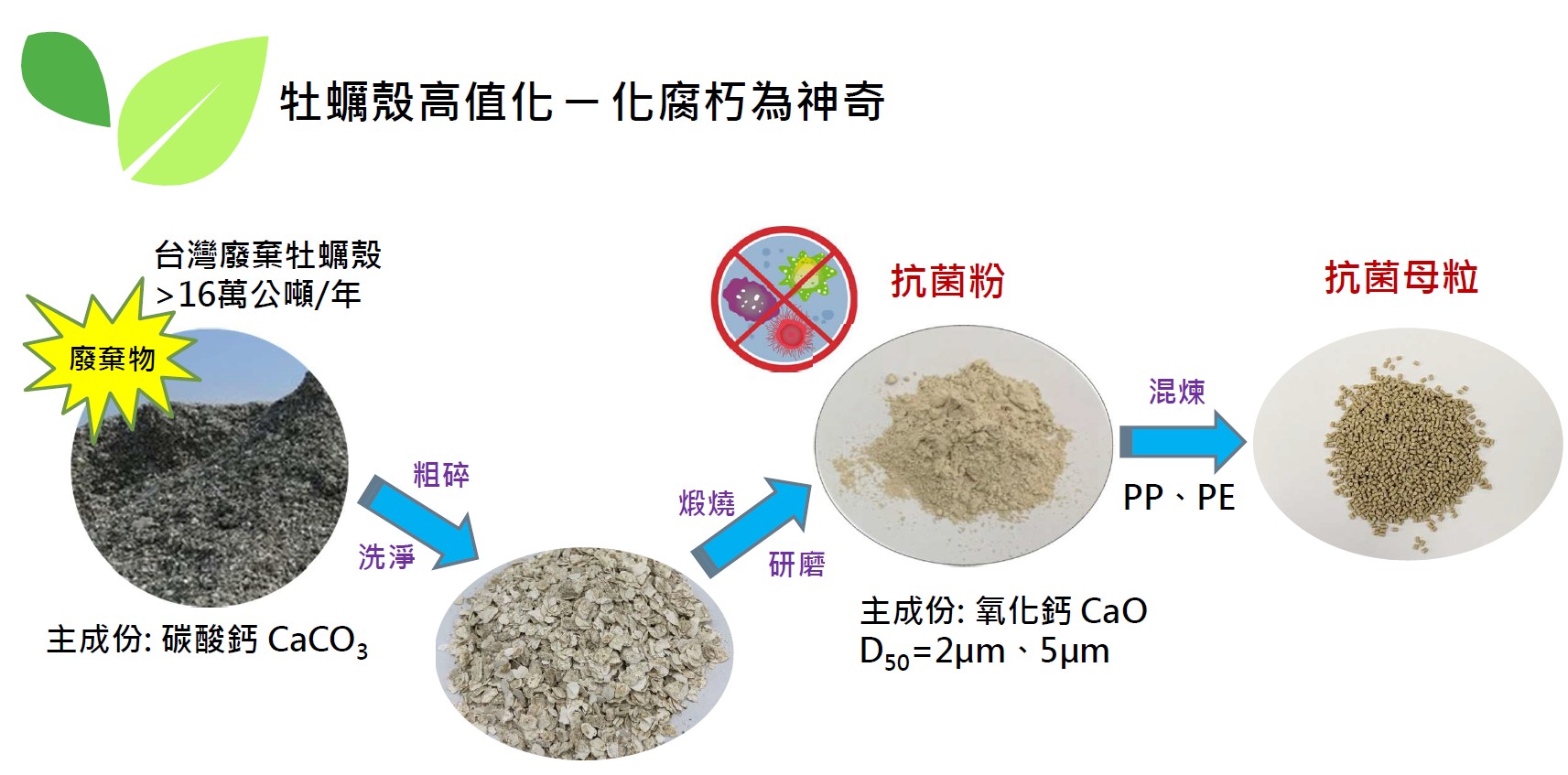

Developing antibacterial composite materials from discarded oyster shells

Taiwan generates an average of 160,000 tons of discarded oyster shells annually. Formosa Plastics Cprporation R&D team transforms these waste oyster shells through calcination and grinding into "Antibacterial Shell Powder" with an antibacterial rate exceeding 99.99%. They combine this antibacterial shell powder with various plastic materials to produce a wide range of antibacterial products. Long-FON DevelopmentLTD. actively embrace ESG principles by incorporating this "Antibacterial Oyster Shell Powder" into their perennially popular air-cushioned slippers, aiming to promote the circular economy. This product has been verified as a "Made in Taiwan" (MIT) product with the MIT Smiling Face Mark. In bending tests, the finished shoes withstood 22,500 cycles without damage and meet the CNS 3478 plasticizer content testing, ensuring that the product is safe for human use and poses no harm, making it a reliable and secure choice.

A footwear group with many years of history, it owns a variety of brands and products. In product development ten years ago, they began to focus on the lightweight and pressure relief of shoes. They used EVA to start a series of research and development. In addition to being lightweight, EVA material is soft, shock-resistant and elastic, which is very consistent with the air cushion concept they want. It can turn the visible (visible airbag) into invisible, so they began to think about how to apply this concept to On other shoes. During a marathon event, they accidentally discovered that some runners were using mother-child crocodile slippers as running shoes. After actually contacting runners and understanding how to use the product, they actively invested in the research and development of a new generation of running slippers. Insisting on the mother-child crocodile made in Taiwan, they designed it according to the foot shape of Taiwanese people and cooperated with the latest high-density, non-toxic EVA material produced by Formosa Plastics. It has not been damaged after multiple normal temperature bending tests. Compared with ordinary Flip-flops, which can better fit the user's arch and foot shape, continue the new generation of road running slippers.

Name:Ms. Tsai

Phone:+886-2-2283-8353

Address:No. 7, Aly. 22, Ln. 95, Zhongshan 1st Rd., Luzhou Dist., New Taipei City 24753

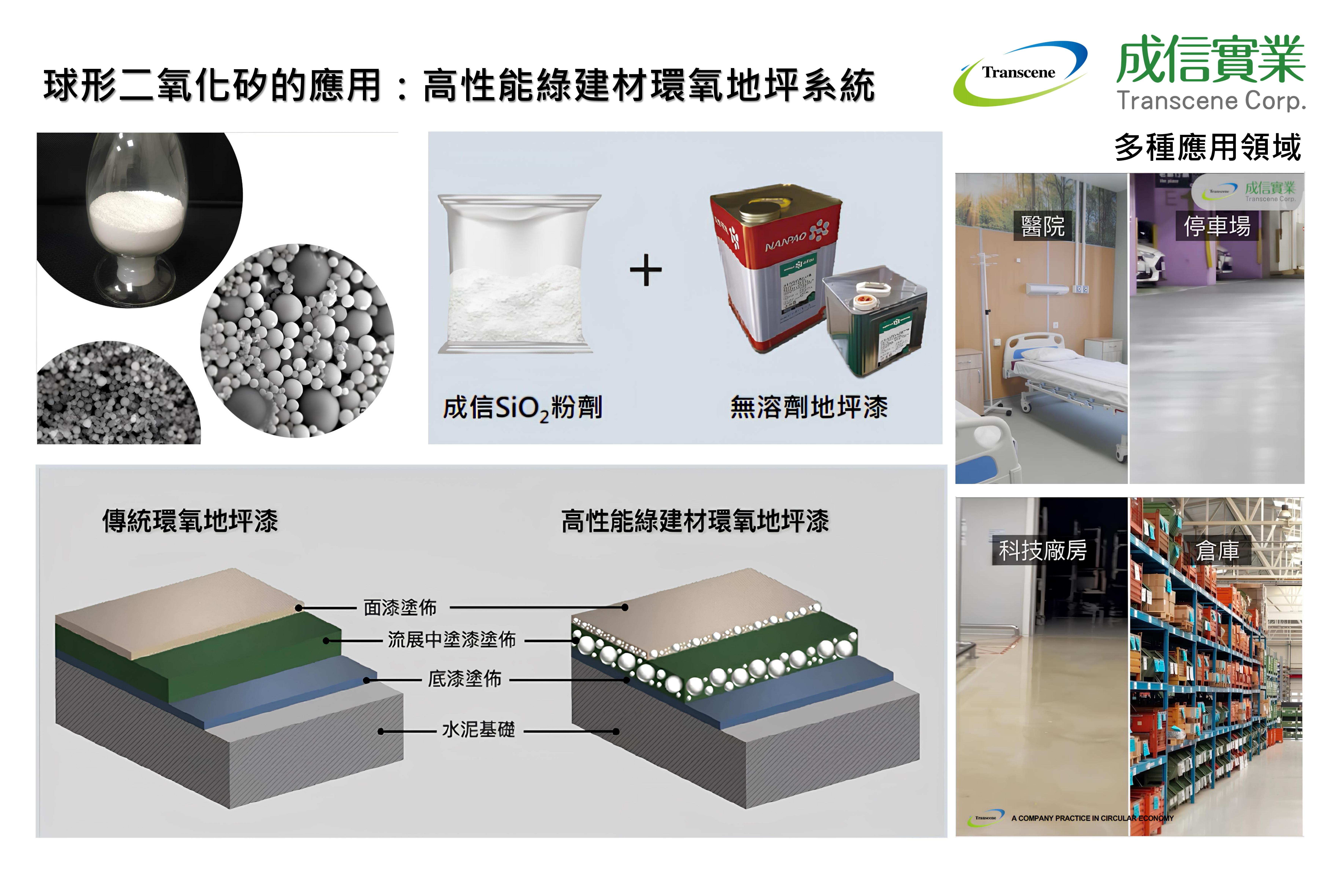

Recycling electronic-grade spherical silica from waste epoxy molding compound using a low-carbon green process

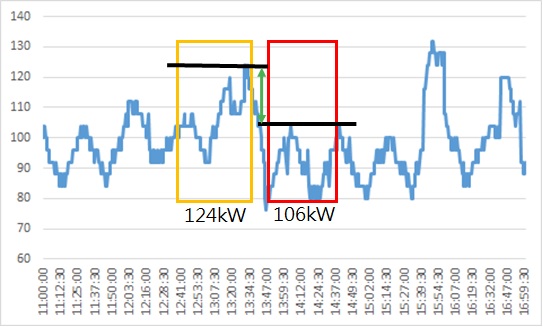

1.Heat pump combined with desiccant for dehumidification & 2.Smart defrost control method & 3.Design of AIoT EMCS communication system & 4.System and Method for a Non-Intrusive Refrigerant Leakage Detection and Adaptive Method for Threshold Thereof

Green adsorption materials and energy-saving exhaust gas treatment equipment used in the treatment of industrial volatile organic compounds

Material Identification Method using Underwater Laser Energy Analysis for Offshore Wind Power Windmill Health Detection

Technology maturity:Experiment stage

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!