Dual-function non-platinum electrocatalyst for hydrogen and oxygen pro duction via water splitting

Electrochemical water splitting is widely regarded as a feasible industrial h

ydrogen production technology that can efficiently convert water into hy

drogen gas. The electrolysis of water can be divided into the hydrogen ev

olution reaction (HER) at the cathode and the oxygen evolution reaction

(OER) at the anode, both of which require a certain overpotential to proce

ed. In industrial applications, the commonly used electrode material for H

ER is platinum (Pt), while the OER electrode often uses precious metal oxi

des such as iridium dioxide (IrO2) and ruthenium dioxide (RuO2). Due to t

he limited reserves and high cost of precious metals, it is challenging for t

hem to support large-scale and low-cost industrial hydrogen production.

Therefore, the development of efficient, long-life, and non-precious metal

(non-platinum) dual-function (applicable to both HER and OER) electrocat

alysts has become an important research topic. Among candidate materia

ls, Ni/Co bimetallic phosphides with outstanding electrolytic properties h

ave received wide attention in this regard. Furthermore, metal-organic fra

meworks (MOFs) composed of transition metals and organic linkers exhibi

t high specific surface area, mechanical strength, controllable active sites,

and multi-scale pore structures. They have great potential in electrocataly

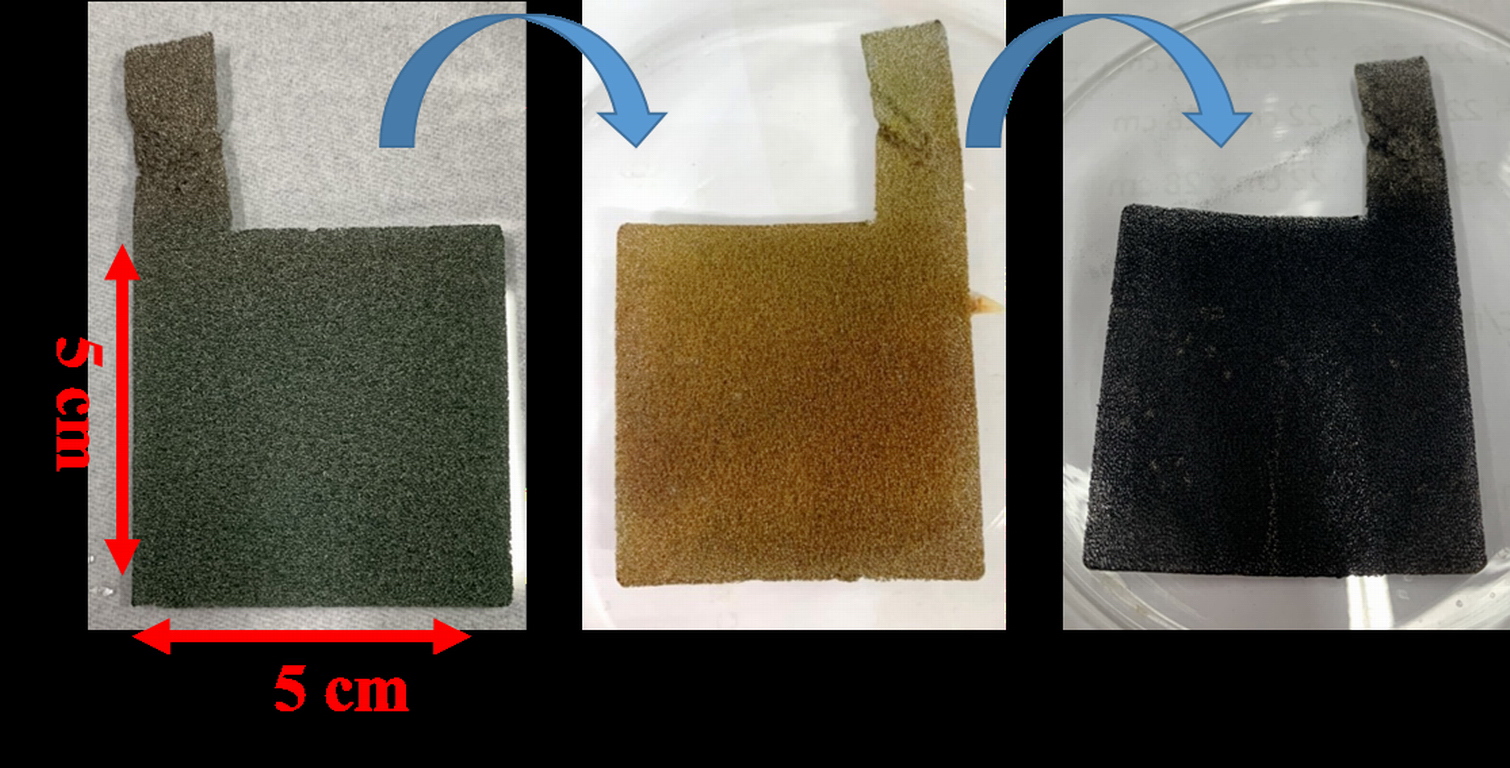

st applications. This technology utilizes an in-situ growth method to grow

Ni/Co bimetallic MOFs on Ni foam substrates and then undergo phosphor

ization treatment to prepare efficient dual-function electrocatalysts for wa

ter splitting. This technique not only has low cost but also improves the el

ectronic conductivity between the electrode and electrolyte, while simulta

neously enhancing the mechanical strength required for gas bubble gener

ation during water decomposition. Our team has also established a large-

area alkaline anion exchange membrane water electrolyzer to evaluate the

feasibility of meeting industrial hydrogen production demands with

At present, the University consists of 16 colleges, 58 departments, 146 graduate institutes, as well as 34 Master's and PhD degree programs. NTU's programs cover a wide array of disciplines across science, arts, and the humanities, with up to 8,000 courses made available for selection each semester.

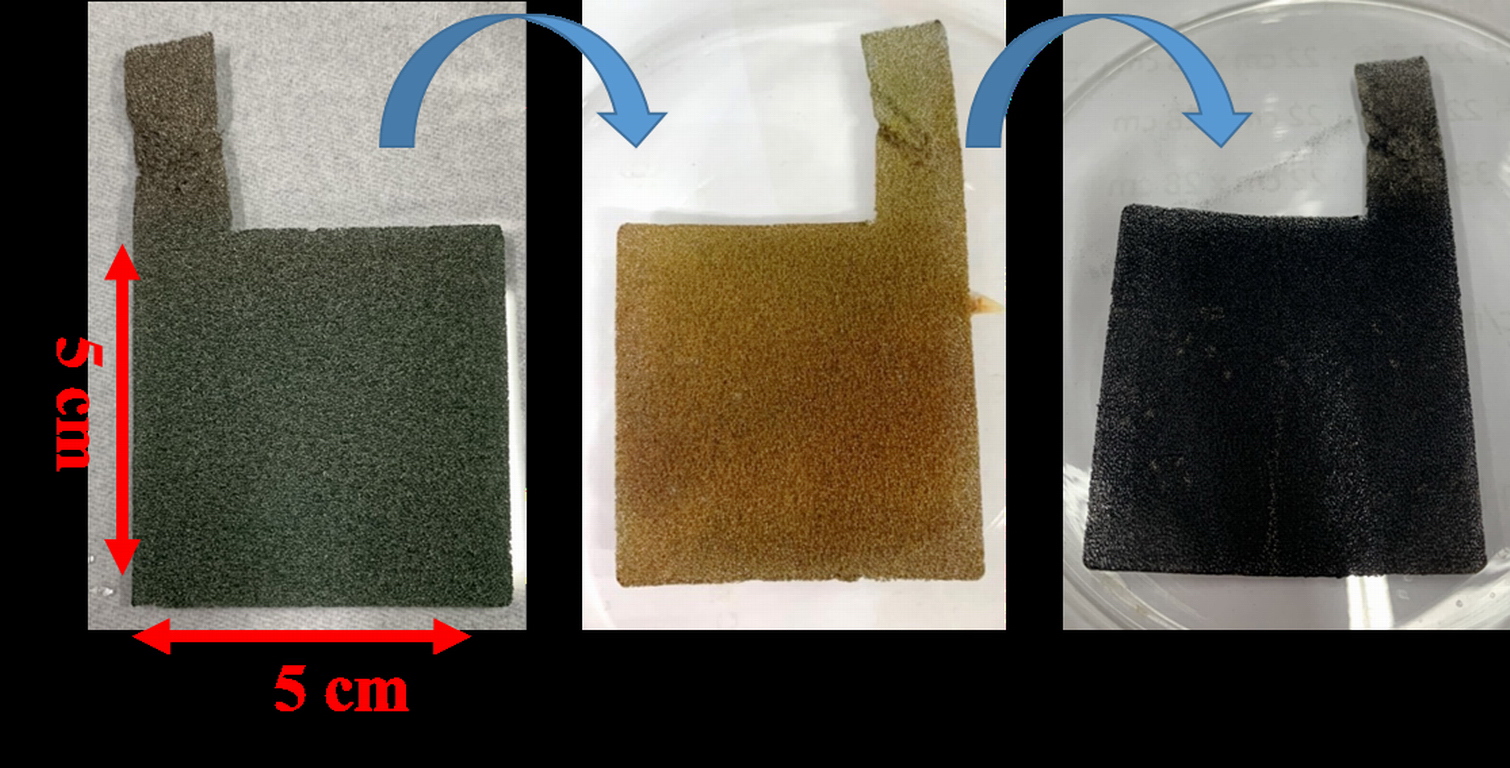

1.Thermal Chemical Conversion Technology-Fast pyrolysis & 2.Technology for catalytic tar elimination and syngas production

High performance proton exchange membrane fuel cell based on laser processed alloy catalyst technique and metal foam flow field bipolar plate with built-in water-cooling design

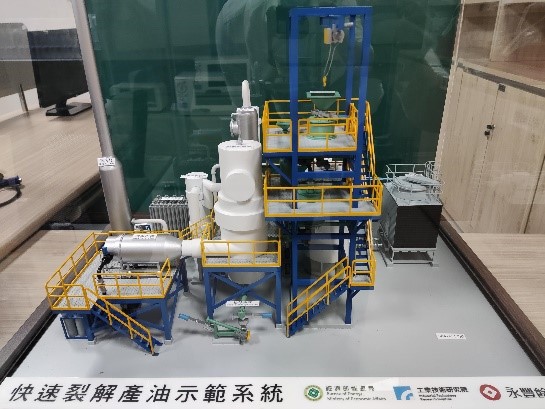

Application of innovative electrolyzed catalytic and nanobubble system for the remediation of petroleum-hydrocarbon contaminated soils and groundwater

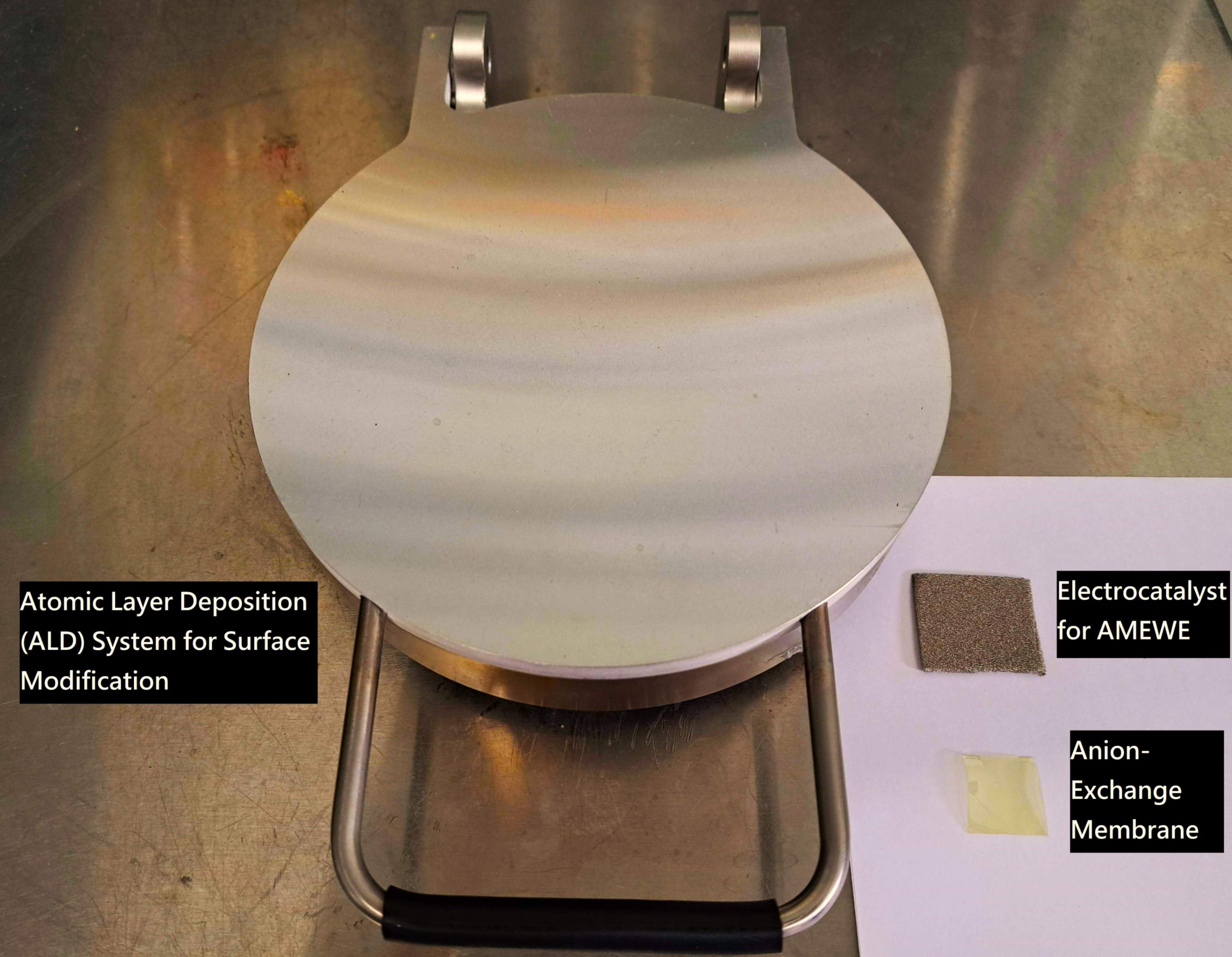

High practicality surface modification technology for enhancing hydrogen production via water electrolysis and solid-state hydrogen storage efficiency

Technology maturity:Experiment stage

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!