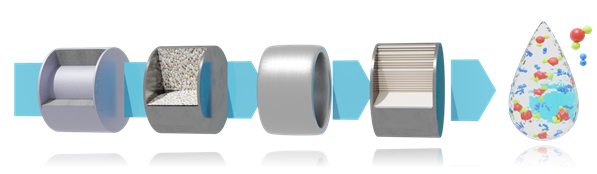

Streamoulding® is a process and equipment solution for light weighting injection moulded plastic products. It is new disruptive technology that uses water as opposed to gas or chemicals as the blowing agent adding it to the polymer in the nozzle rather than the barrel of the injection moulding machine. The equipment is low cost relative to competitors, retro fit, and is easily installed and moved between injection moulding machines.

The Streamoulding® equipment consists of a replacement mixing nozzle and a separate control plinth. To operate, it only needs compressed air and a single-phase power supply and a volt free connection from start of injection from the moulding machine.

The technology produces a cellular structure with a surface skin and will work across a range of unfilled and filled materials. Weights savings in the region of 8 -10% are typical given the right application. Additional benefits from cycle time reductions, clamp force reductions and energy savings are also typically achieved.

The surface finish produced gives a marbling effect which is typical of foaming processes. This can be improved markedly with the addition of rapid mould heating/cooling technologies.

ROI’s can be less than 12 months for some applications

Key markets are packaging and automotive generally with larger parts giving the best results and savings.

U.S. Patent 10,038,338 Signal modulation method and signal rectification and modulation device

U.S. Patent 8,729,852 Method for identification of a light inductive charger

U.S. Patent 8,217,621 Frequency modulation type wireless power supply and charger system

Combined Water Treatment Technology for non-electrical production of Alkaline, Hydrogen-rich drinking water with prolonged retention rate of target value frames

技術成熟度:試量產

展示目的:商機推廣

流通方式:專利授權/讓與、自行洽談

*服務單位

*姓名

*電話

*您參觀這項展品的主要目的?

*您是否希望進一步洽談

*您的職務類別

*展覽整體評價

*最喜歡的展區

*期待展覽著重的技術領域

*是否願意收到電子報/最新資訊

其他建議

敬請期待!