Micro inductive tactile/force sensing chip for the applications of force detection and human-machine interface

This project exploited the mature and commercially available standard CMOS process to develop the micro tactile/force sensor.

About the sensor design: novel inductive sensing mechanism instead of existing piezoresistive and capacitive sensing mechanisms is chosen to implement a robust (for both fabrication and operation) tactile sensor. The device can be easily fabricated using existing semiconductor process technologies and could also tolerate higher overload. Since no suspended thin film structure is required for the proposed sensing mechanism, many technical problems such as the stiction of released structures, the initial deformation due to residual stress…etc. can be avoided. As a result, the proposed design could enhance the reliability and yield of tactile sensor.

About the fabrication processes: the standard commercially available CMOS platform is exploited to implement the proposed tactile sensor, and no customized special fabrication processes are required. In other words, as the concept of proposed tactile sensor is demonstrated, it is ready for mass production.

Moreover, the proposed inductive tactile sensor chip has a very small footprint (below 2mm), which can be easily integrated into the consumer electronics devices, such as smart phone, smart watch, etc. In summary, the proposed tactile sensor can find broad applications for products which require the force detection or the tactile load as the human-machine interface.

National Tsing Hua University (NTHU), established in 1911 and located in Hsinchu, Taiwan, is one of the top research universities in the country. NTHU offers a wide range of programs in fields such as engineering, science, management, and humanities. The university is known for its strong emphasis on innovation, research excellence, and fostering global perspectives. With a commitment to academic rigor and interdisciplinary collaboration, NTHU plays a key role in advancing knowledge and technological development, contributing to both Taiwan’s growth and the global academic community.

Remanufacture of high value products using a combined laser cladding, inspection and 5-axis machining system

A image analysis system applied to the detection of the number of graphene layers and method of use thereof

Combined Water Treatment Technology for non-electrical production of Alkaline, Hydrogen-rich drinking water with prolonged retention rate of target value frames

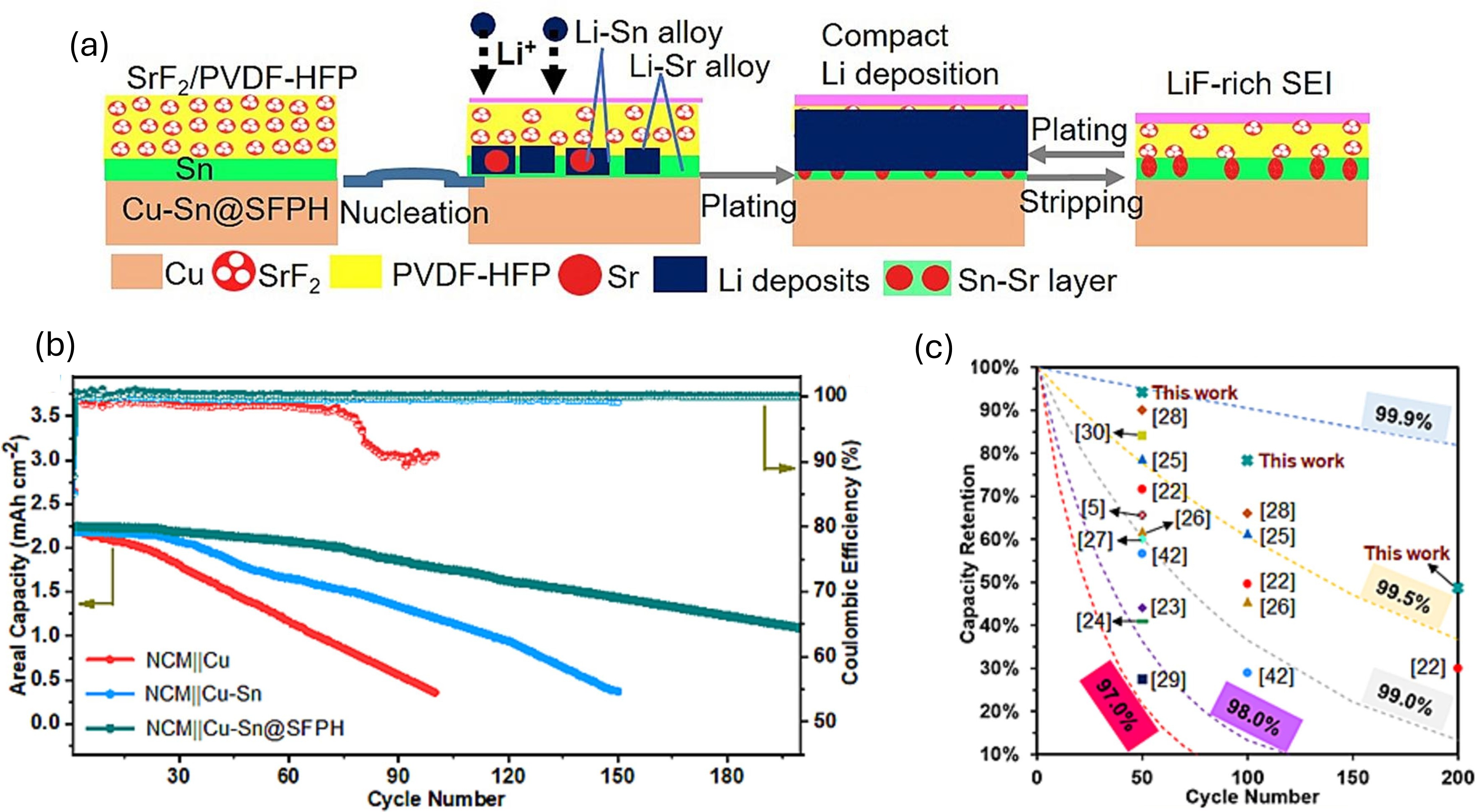

Multiple protective layers for suppressing Li dendrite growth and improving the cycle life of anode-free lithium metal batteries

Technology maturity:Experiment stage

Exhibiting purpose:Technology transactions、Product promotion、Display of scientific results

Trading preferences:Negotiate by self、Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!