Remanufacture of high value products using a combined laser cladding, inspection and 5-axis machining system

Remanufacturing of recycling worn parts consumes only a fraction of the energy, cost, and material required for new parts. Remanufacture of engineering components typically entails serial labor intensive and operator skill sensitive processes, often requiring parts to move between manufacturers and subcontractors. Unfortunately the logistics and quality assurance measures required for effective remanufacturing currently restrict its implementation to high value components.

This innovative technology of complicated process based on the structure of machine tool which combines laser cladding, machining, in-process scanning and laser heat treatment in a single machine tool. This machine melts metal powder using fiber laser heat. Cladding heads apply the molten material layer by layer, each of which solidifies as the desired shape grows. The machine can join different types of metals together, which allows for the efficient repair of existing worn or damaged components such as aerospace turbine blades.

As part of the hybrid process the cladded tool is milled every few cladding layers so that the small diameter cutters can be used to reach every feature of the tools before the next layers are added. Small milling cutters can be used to mill very small corner radii so that the innovative technology will be capable of replacing electrical discharge machining (EDM) on many tools.

It is perfect for small volume production of very difficult-to-cut materials, this hybrid process (coupling additive and subtractive processes) uses its additive capability to easily generate near-net-shape component features and then completes them through the high-precision 5-axis machining operations. The process can produce fully dense metal parts with complex and accurate parts. Therefore, it is potentially a very competitive process to fabricate metallic structures.

Wide Band Gap Semiconductor Based Ultrahigh Efficient Binary Multilevel Inverter for Utility PV and Fast EV Charging Systems

Micro inductive tactile/force sensing chip for the applications of force detection and human-machine interface

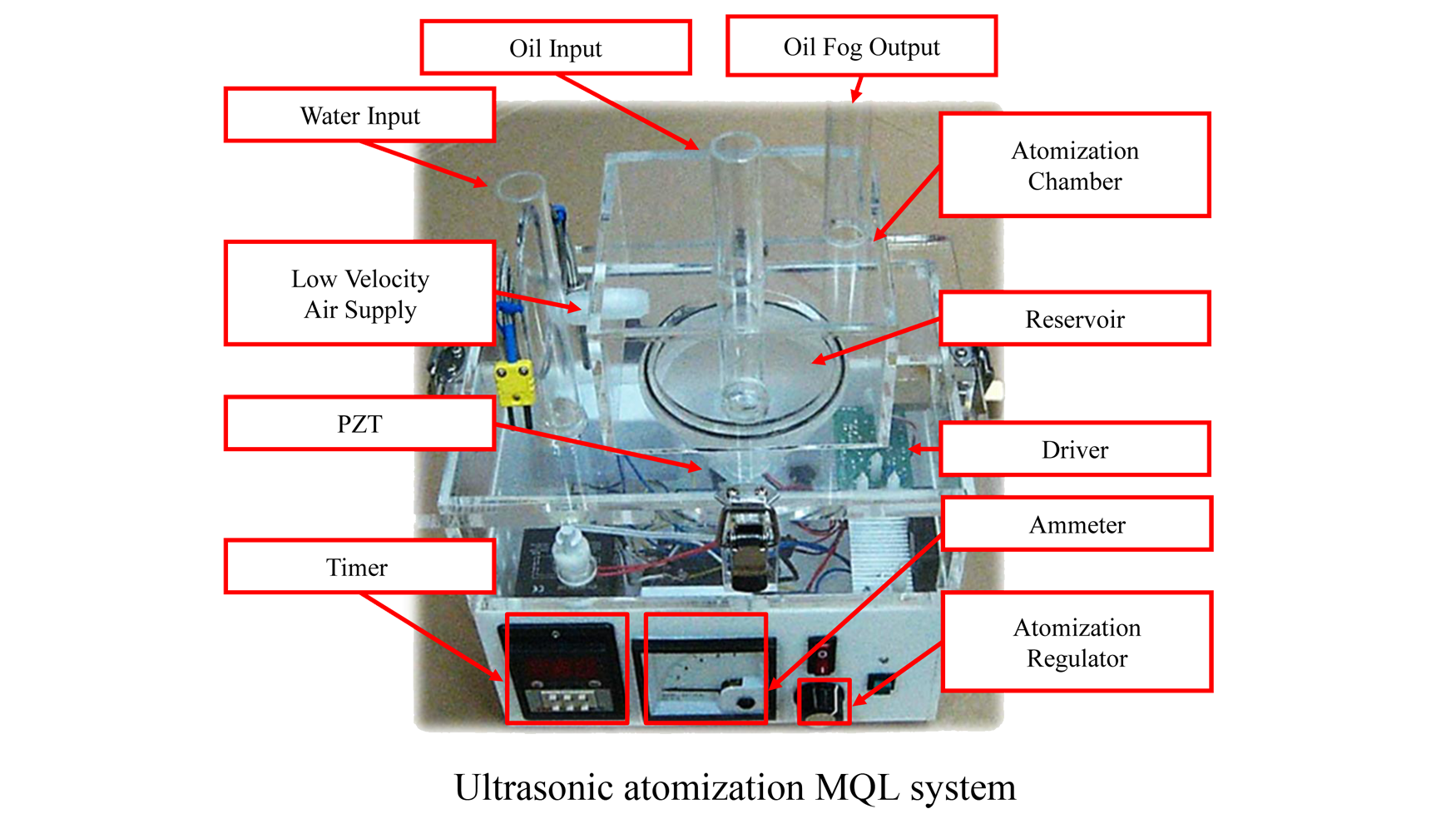

Nanofluid/ultrasonic atomization micro-lubrication system development and application intelligent modeling method to improve the multiple quality characteristics of the micro-machining process research and optimal prediction model establishment

Combined Water Treatment Technology for non-electrical production of Alkaline, Hydrogen-rich drinking water with prolonged retention rate of target value frames

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Display of scientific results

Trading preferences:Technical license/cooperation

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!