System Design and Manufacture of Ultrasonic Tool Kit Base on Wireless Transmission Technology

Special brittle materials are now the mainstream materials of major commodities. If there is no breakthrough in processing technology, problems such as extremely easy tool damage, severe wear or fracture of the workpiece will eventually occur. To solve such a problem, ultrasonic processing is a great way in the industry. It needs no change to the traditional machine tool operation methods and will not greatly damage the original operating experience. Moreover, micro-vibration can be applied stimulatingly in the process of milling, grinding, drilling, etc. The process is more suitable for mainstream brittle materials.1.The ongoing two-year industry-academic cooperation plan of the MOST, "The development of ultrasonic cutting tool kit with wireless power transmission technology".

2.Patent output: This technology has obtained a new type patent and an invention patent has been submitted for review. Besides, paper submissions to other related journals have also been planned.

3.Technology transfer: Technology transfer arrangements have been established with Puu Lih Precision Spindle.

4.Technological breakthroughs: Currently, the contactless transmission technology belongs to the German machine tool manufacturer DMG MORI. Therefore, to become the vanguard of the contactless power transmission ultrasonic cutting tools, our team has successfully gone through the major technical bottlenecks.The goal of this technology is very clear, which is to assist the processing through the micro-vibration generated by the ultrasonic cutting tools, to greatly increase the output value, improve the quality and reduce the cost without significantly damaging the operating experience. It greatly contributes to the processing technology and additional commercial value of domestic manufacturers.

Some of the most popular programs at NCYU include Mechanical Engineering, Electrical Engineering, Information Management, Environmental Engineering, and Finance. The university also offers programs in fields such as Applied English, Digital Media Design, and Industrial Design.

Name:姚賀騰

Phone:04-2392-4505#7229

Address:No.57, Sec. 2, Zhongshan Rd., Taiping Dist., Taichung 41170, Taiwan (R.O.C.)

The Intelligent Cloud Platform for the Machinery Industry and on-premise Taiwan Machinery Standard Runtime networking technologies.

Remanufacture of high value products using a combined laser cladding, inspection and 5-axis machining system

Prevention and Mitigation of Multi-functional Geotechnical Seismic Isolation Technique

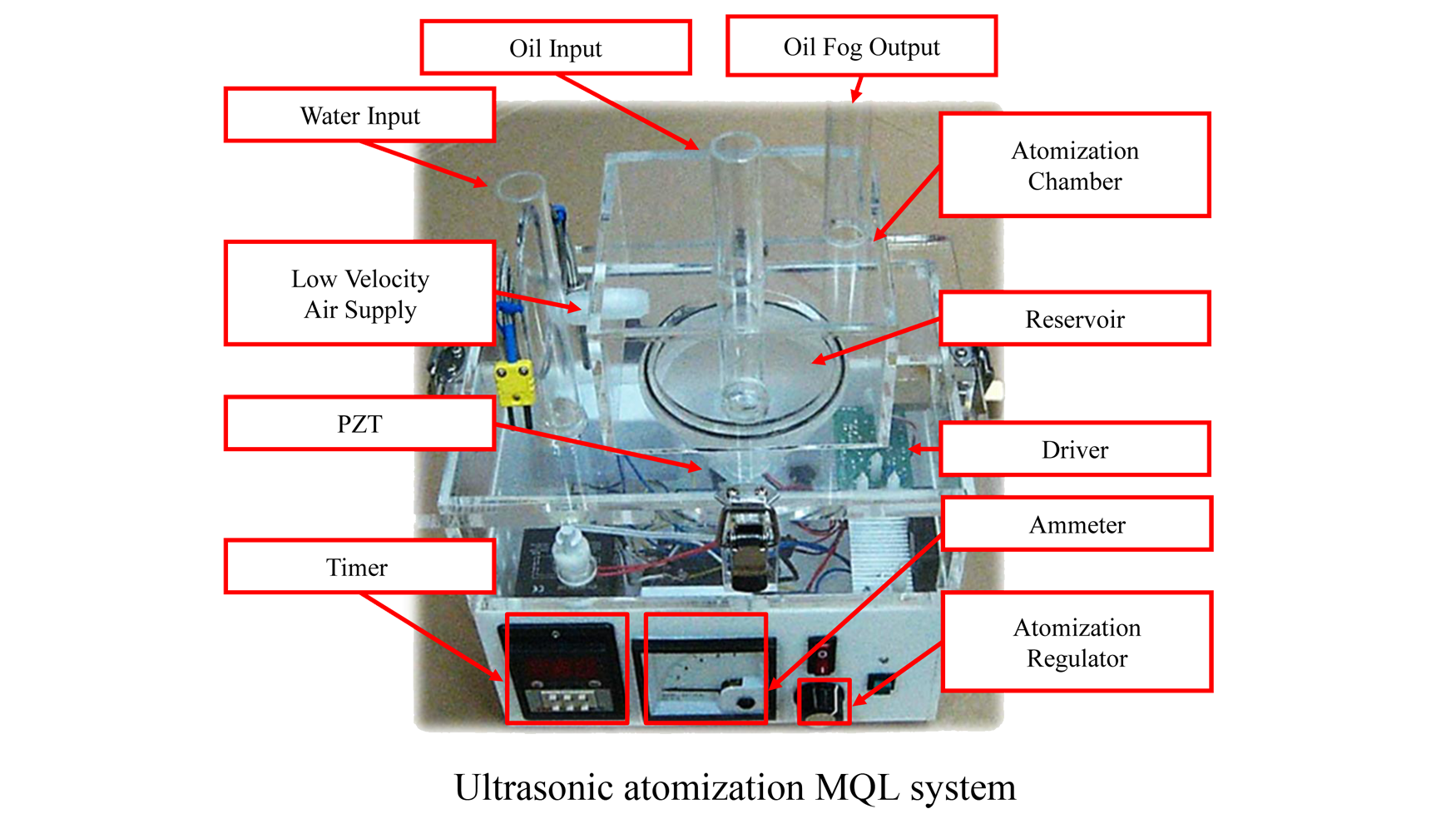

Nanofluid/ultrasonic atomization micro-lubrication system development and application intelligent modeling method to improve the multiple quality characteristics of the micro-machining process research and optimal prediction model establishment

Technology maturity:Trial production

Exhibiting purpose:Technology transactions、Patent transactions、Product promotion、Display of scientific results

Trading preferences:Technical license/cooperation、Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!