In response toTaiwan's ambitious 2050 net-zero emissions target, NCSIST is harnessing its expertise in electrolysis, hydrogen storage alloys, composite gas storage cylinders, and fuel cell technology. By linking up with renewable energy sources such as wind and solar power, as well as off-peak electricity, NCSIST aims to create a comprehensive hydrogen energy system. Through electrolysis, hydrogen can be produced and stored, providing a flexible energy carrier that can be used in mobile or distributed power stations. As Taiwan heavily relies on imported fossil fuel, this domestic produced, mobile hydrogen energy offers a strategic advantage, enhancing the resilience of the national power grid. The first domestic anion exchange membrane stacked hydrogen production module, and completed the entire process development of independent catalysis electrode sheets, with a self-made rate of 80%. It has the characteristics of small size, high gas production rate, low energy signal, high energy conversion rate, low price and easy installation. The highlight of this product is that the self-developed non-precious metal catalyst electrode. The application are green hydrogen, offshore wind power or solar energy is converted into hydrogen storage and electricity generating system. Applications: Military: Hydrogen fuel vehicles, distributed military power stations, mobile emergency power sources, and strategic energy storage systems. Civilian: Green hydrogen, energy storage systems, power generation systems, and chemical synthesis applications.

Develop national defense science and technology capabilities, establish an independent defense industry, and develop national defense and military and civilian science and technology.

Name:Hao,Chia-kan

Phone:(03)4712207#358270

Address:No. 481, Sec. Jia-an, Zhongzheng Rd., Longtan Dist., Taoyuan City

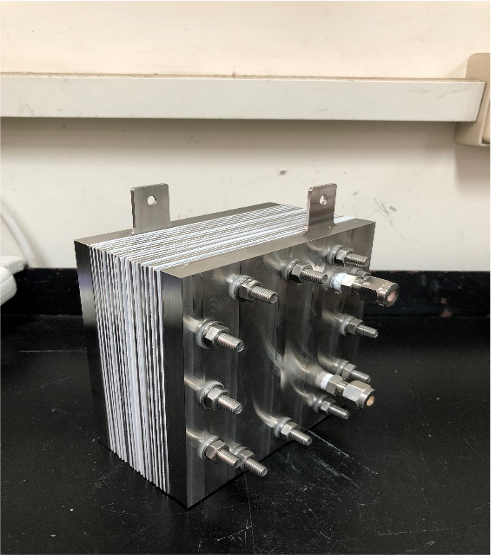

Designed Janus Transition metal dichalcogenides Nanowall Electrodes with High Faradaic Efficiency for Nitrogen Reduction

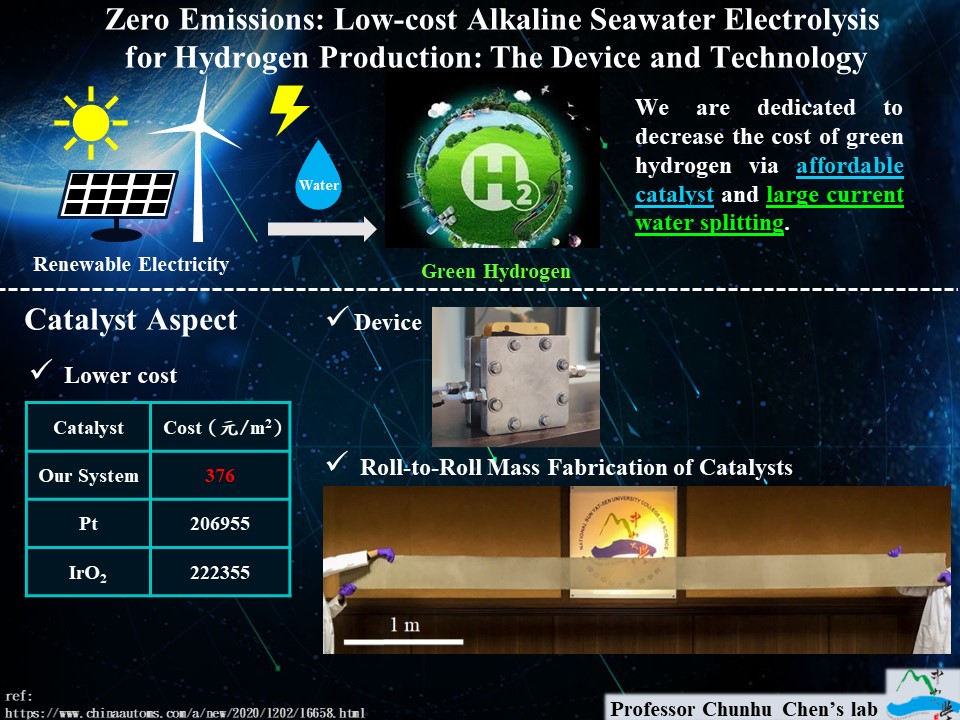

Zero Emissions: Low-cost Alkaline Seawater Electrolysis for Hydrogen Pro duction: The Device and Technology

.png)

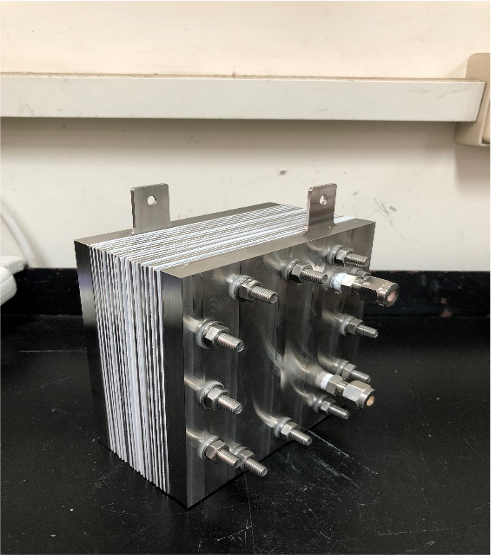

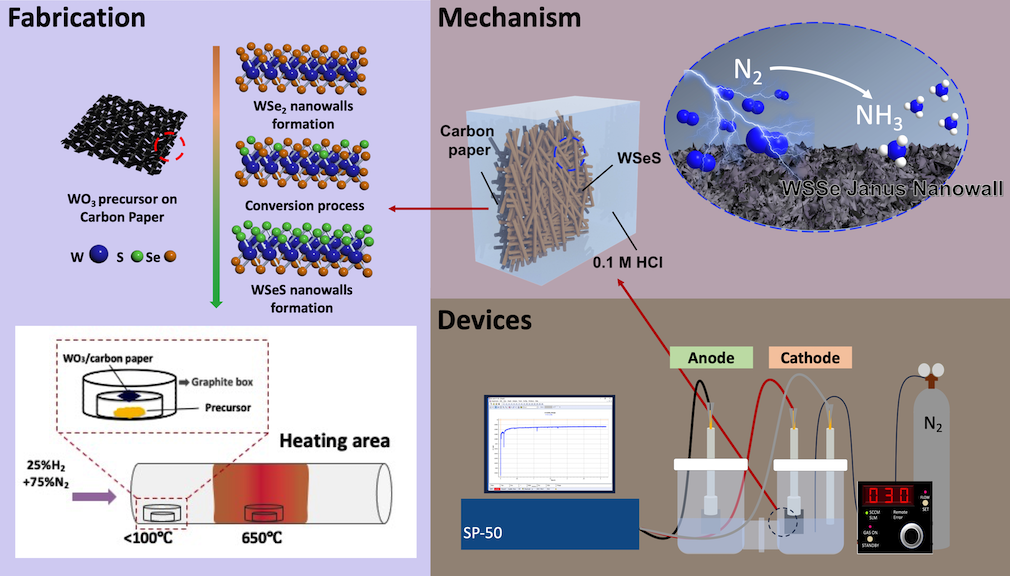

Cost-Effective Anion Exchange Membrane Electrolysis for Green Hydrogen Production

High performance proton exchange membrane fuel cell based on laser processed alloy catalyst technique and metal foam flow field bipolar plate with built-in water-cooling design

Technology maturity:Prototype

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!