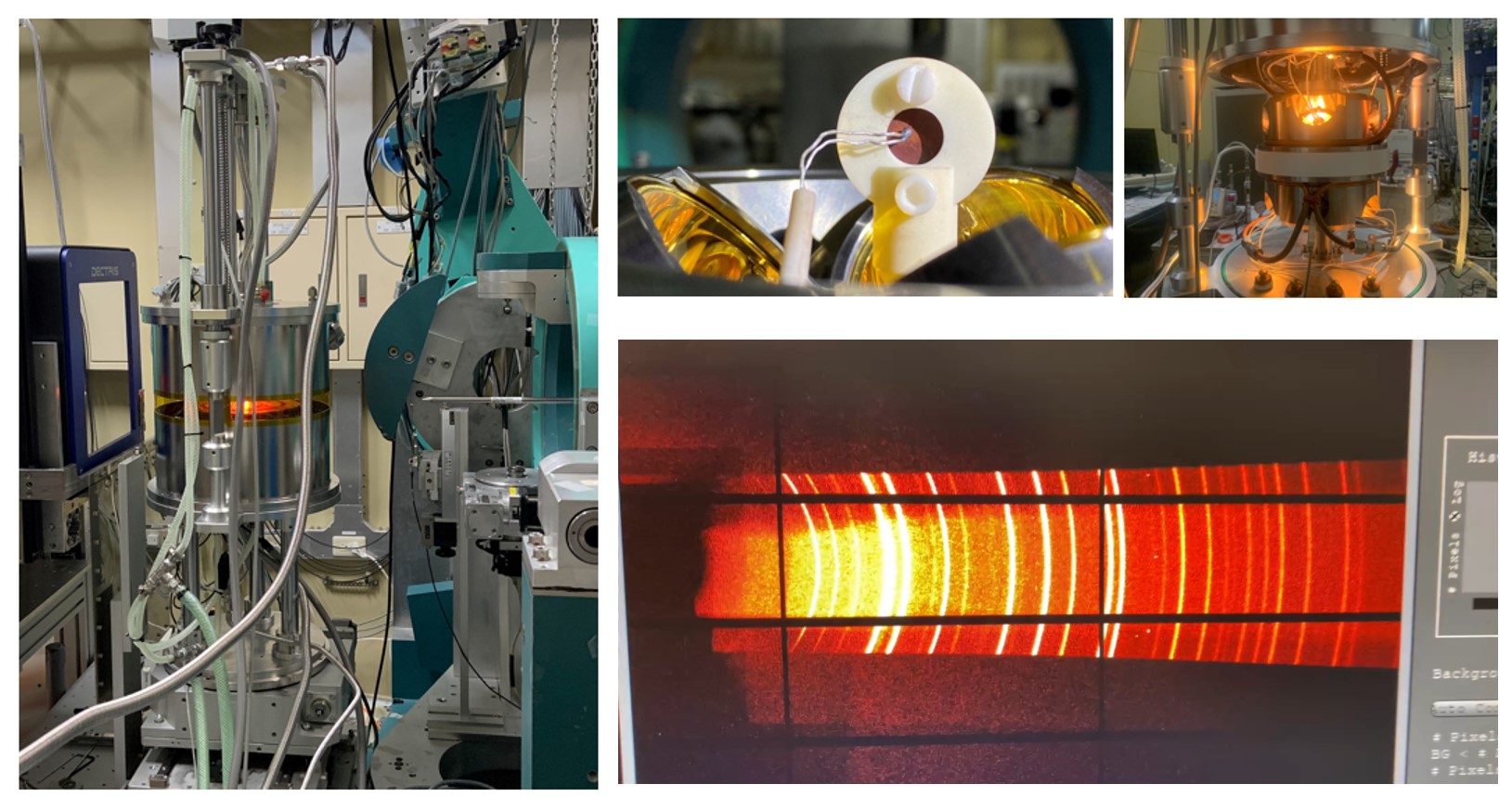

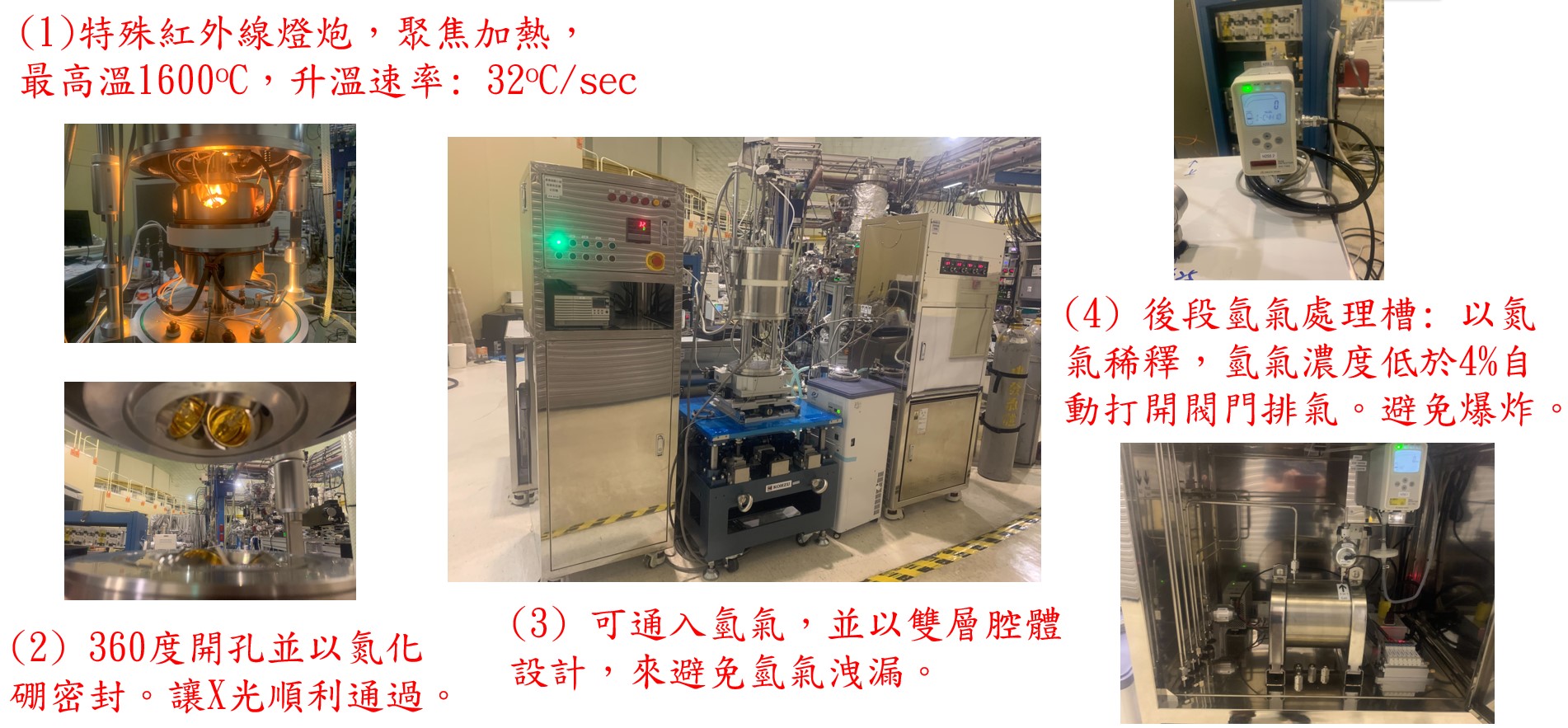

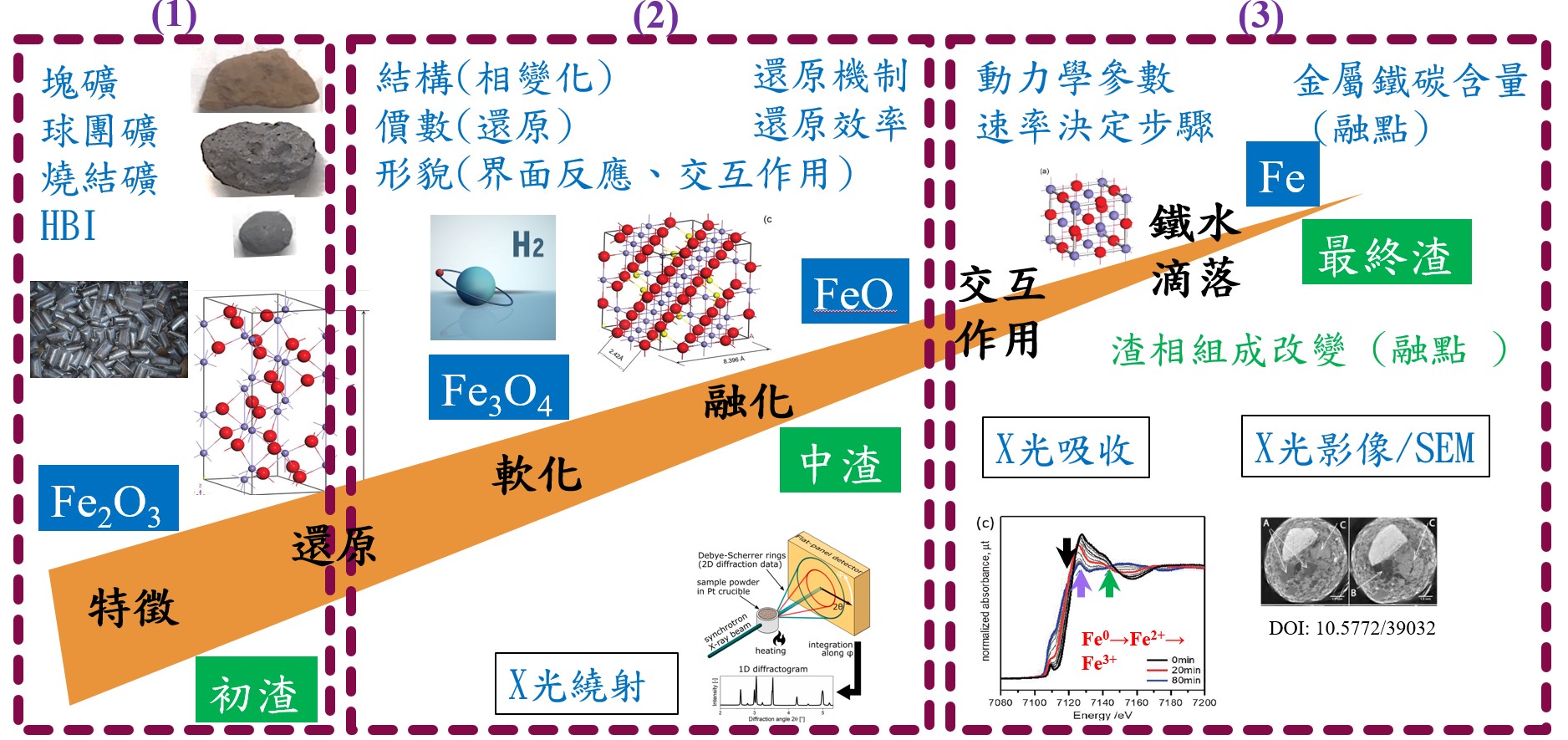

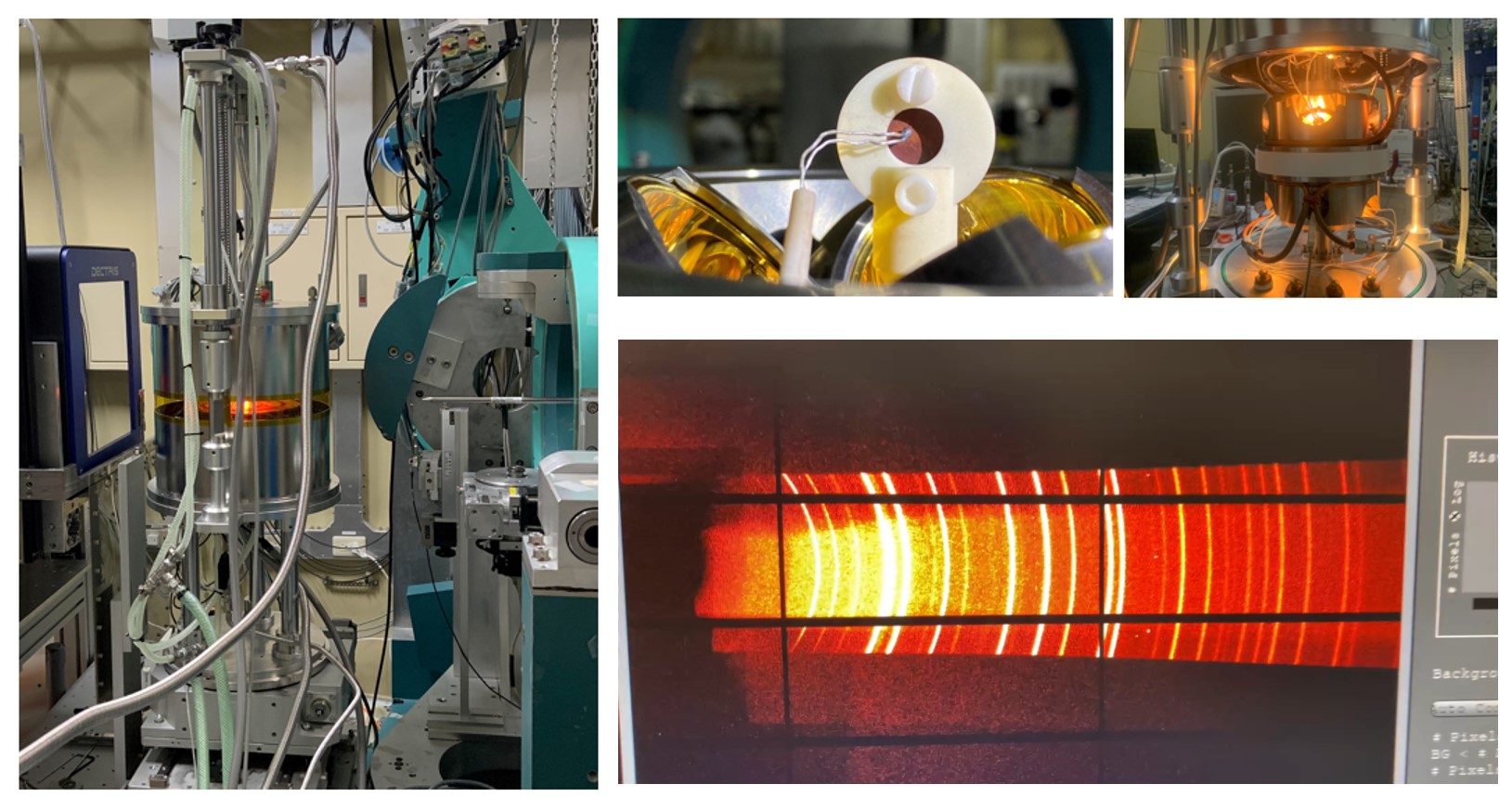

Refining area at 1600°C: Advanced synchrotron X-ray views into the black box of blast furnaces, understands ironmaking process, and illuminates the bright road to net-zero carbon emissions

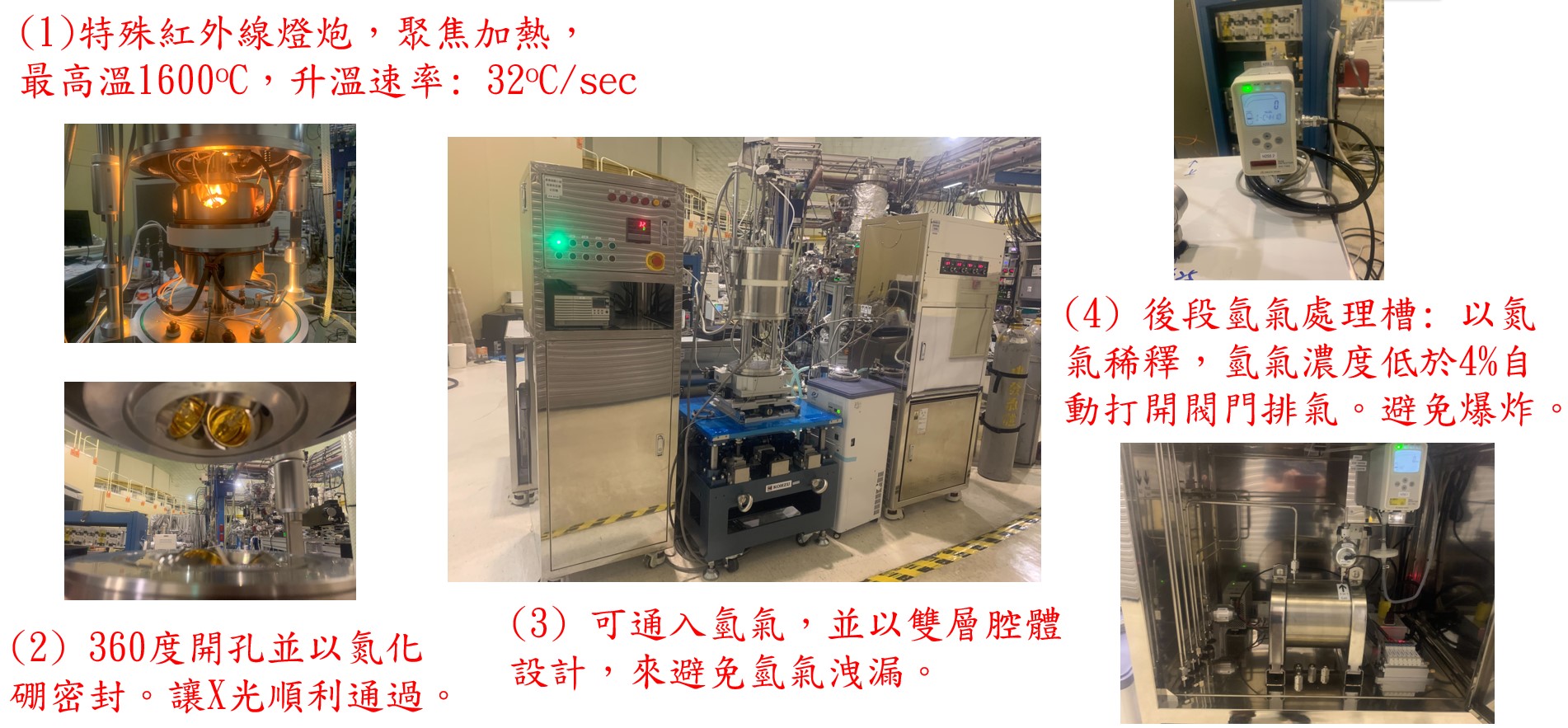

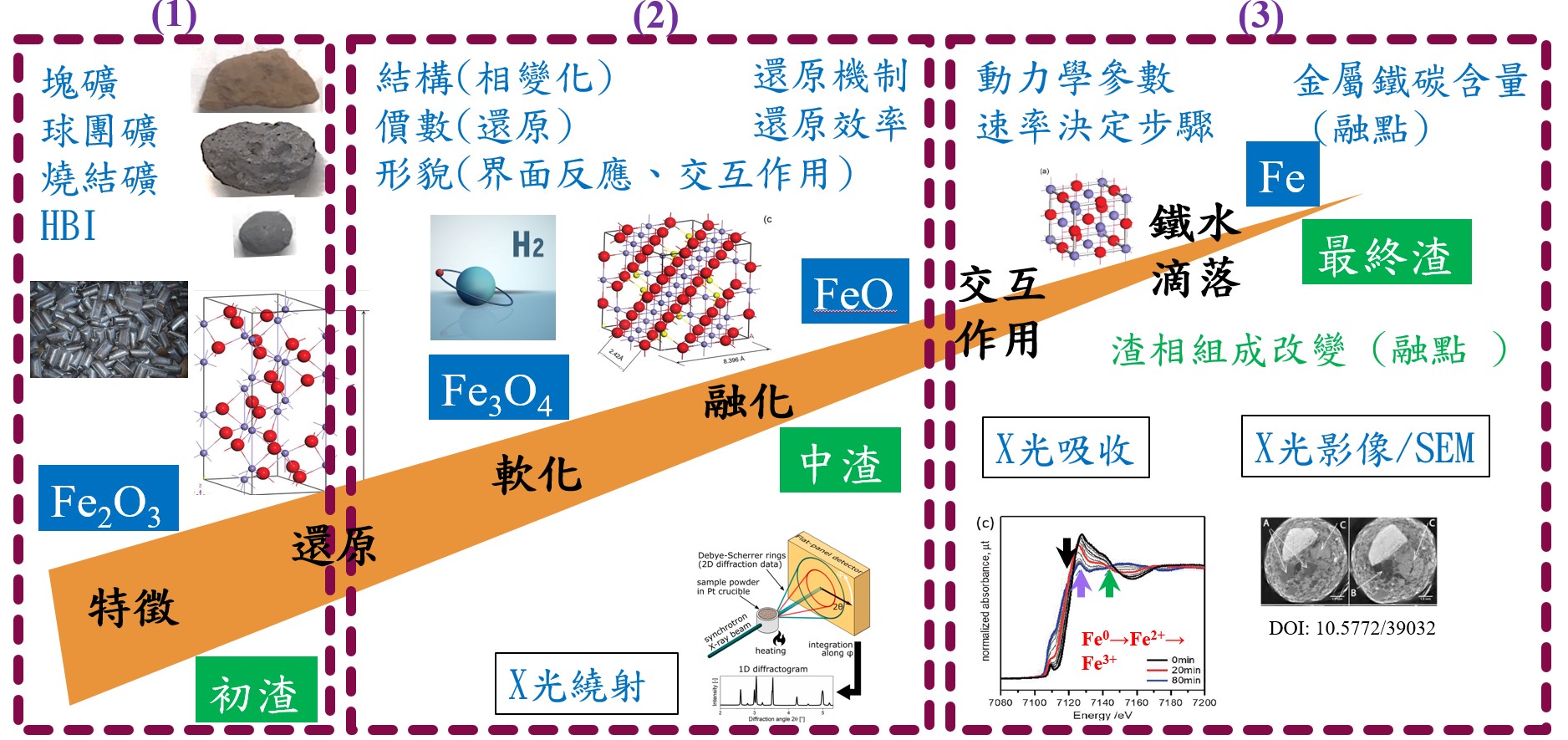

The most effective method to reduce carbon emission in a blst furnace is to use hydrogen, substituting coke, to reduce iron ore. However, the mechanism as well as kinetics of iron ore reduction by hydrogen is still not understood clearly that hinder the use of hydrogen in practice. We thus construction an in-situ chamber to faciliate synchrotron X-ray analyses under high temperature and hydrogen environment simultaneously. Result is of great help to control parameters of a blast furnace and reduce carbon emission by using hydrogen successfully.

NSRRC, the biggest large-scale shared research facility in Taiwan, currently operates two accelerators, the Taiwan Light Source (TLS) and the Taiwan Photon Source (TPS). TLS, of beam energy 1.5 GeV and circumference 120 meters, is the first third-generation synchrotron light source facility in Asia and the third globally. It has opened to users since October, 1993. The best optimized energy range of synchrotron light from TLS is between vacuum ultraviolet light and soft X-rays. The TPS, of circumference 518.4 meters, is one of the brightest synchrotron light sources in the world. It began its operation in September, 2016. To meet the demands from modern technologies and pioneer sciences for higher-brightness light beams, such as biomedicine and nanoscience, it is equipped with a low-emittance synchrotron storage ring and booster synchrotron producing a beam of energy 3 GeV. It generates X-rays in the higher energy range from soft X-rays to hard X-rays, and has a capacity of more than 40 beamlines. In addition, NSRRC built and operates two hard X-ray Taiwanese beamlines at SPring-8, Japan, as well as a cold neutron triple-axis spectrometer at the Australian Nuclear Science and Technology Organisation (ANSTO), under the international collaboration agreements. Scientists from around the world can access NSRRC’s facilities to explore the properties of materials in a wide range of disciplines through a competitive proposal process. Every year, over 2,000 users use NSRRC’s experimental facilities, which not only enable basic research, but also facilitate high-tech innovation. NSRRC possesses one of the most advanced synchrotron facilities in the world and its pioneering capabilities keep Taiwan at the forefront of scientific research.

The innovative technology that turns waste into treasure – Silicon Dioxide regenerated from semiconductor waste that contains Silicon

Hybrid CMOS Inverter Comprised of Thin Film Transistors with Hetero-channel for Monolithic 3D-ICs and Ultra-high Resolution Flat-Panel Displays Applications

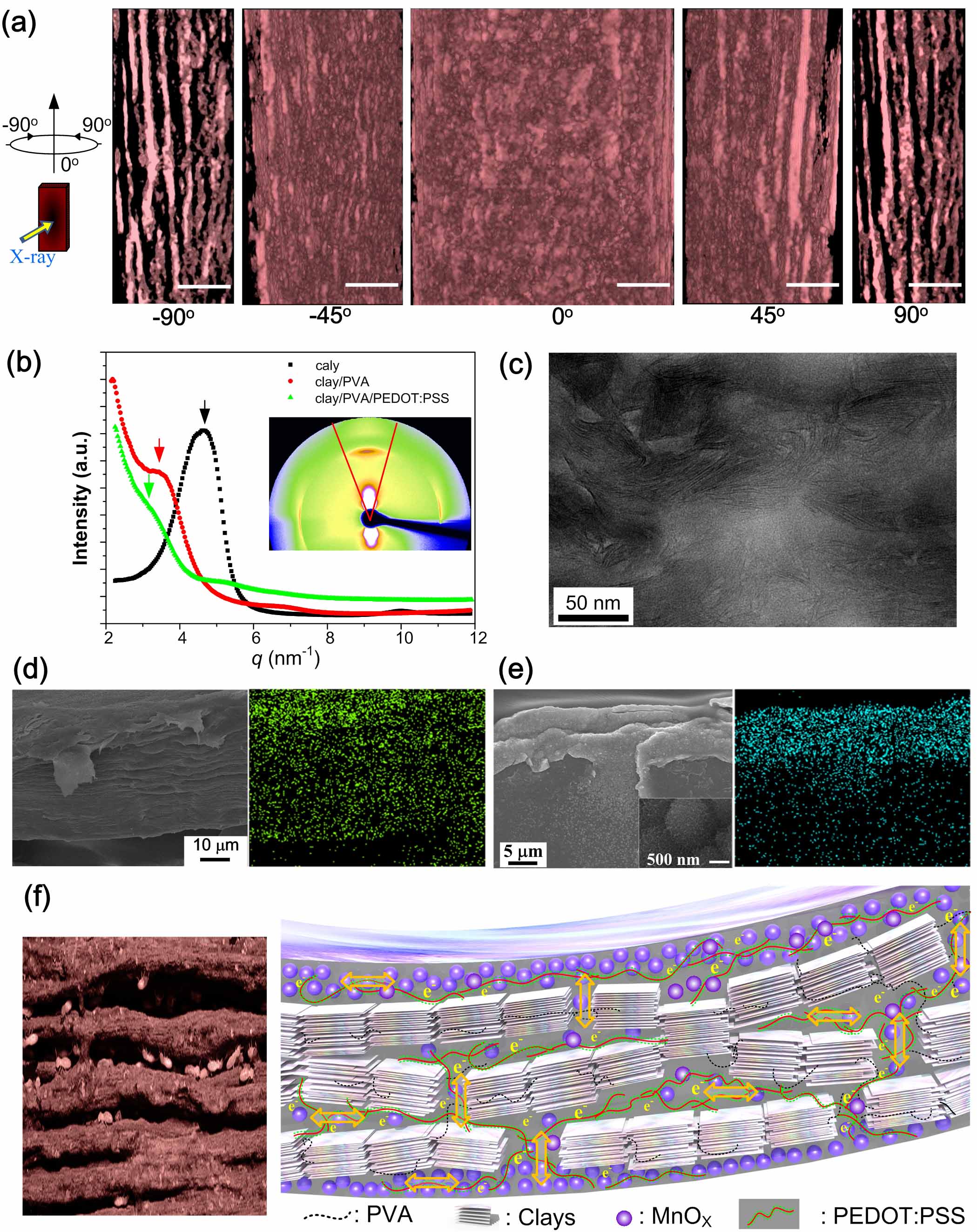

Next-generation energy for wearable device: bioinspired, eco-friendly, and felxible all-solid-state supercapacitors

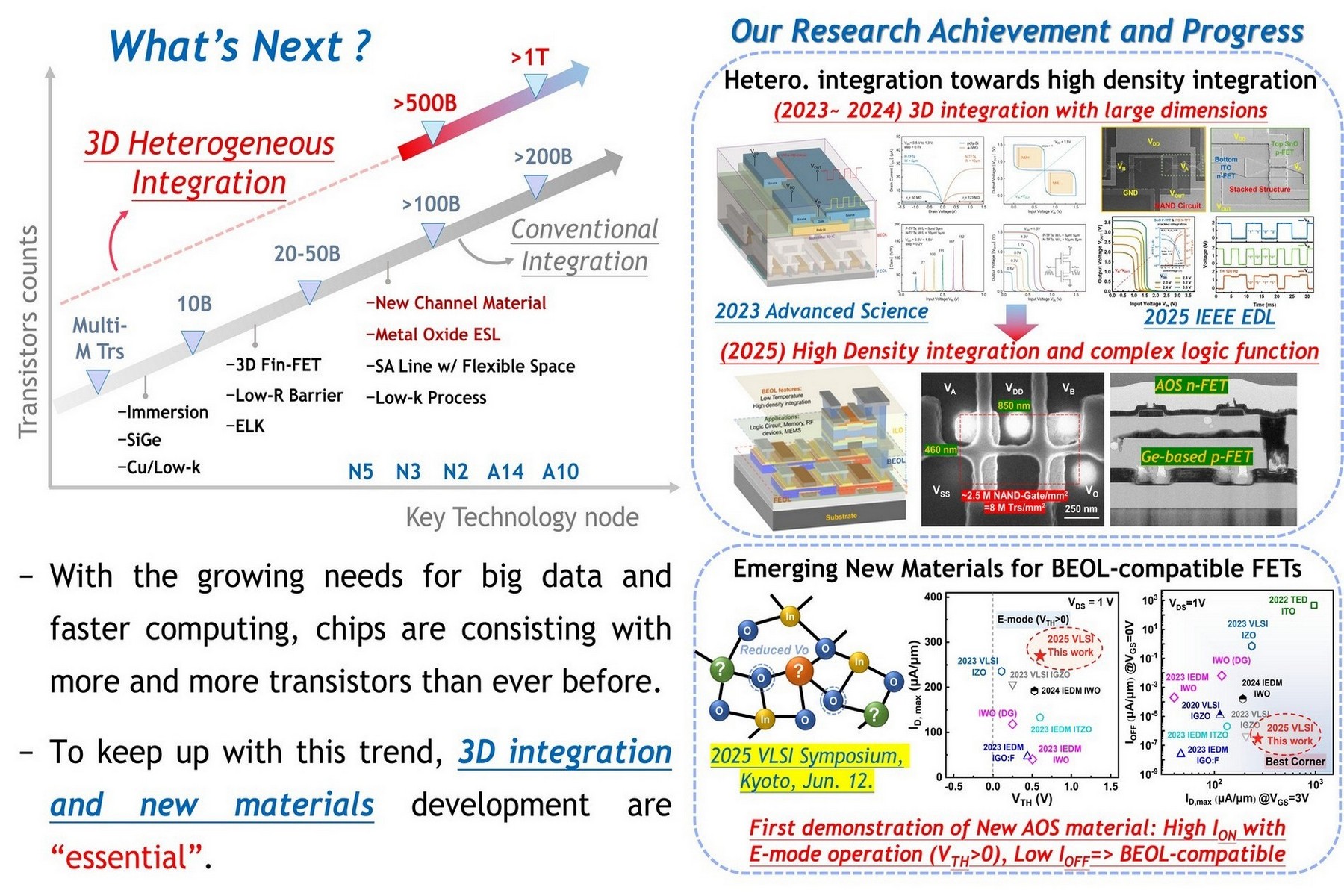

Monolithic 3D Heterogeneous Device Integration and Innovative Materials for Breaking Logic Density Limits: A Key Technology Platform for High-Density AI Computing Chips

Technology maturity:Prototype

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!