(1) Global Target of Carbon Neutrality by 2050: "Triple Carbon" Pressures

Driving Innovations

The World Bank reported that global carbon pricing revenue reached $53

billion in 2020. By 2030, carbon prices are projected to rise to $160 per to

n. The European Union proposed carbon tariffs, leading to changes in poli

cies, technology, and talent development worldwide.

(2) Steel Plants as Major Carbon Emitters: Decarbonization Focus on Blast

Furnace

The steel industry generates 3 billion tons of CO2 emissions annually, acco

unting for 9% of global emissions. Blast furnace ironmaking, responsible f

or 70% of these emissions, relies on energy and fossil-based reducing age

nts, resulting in significant CO2 emissions. Decarbonizing blast furnaces is

crucial for achieving net-zero emissions.

(3) Essential Pathway for Steel Plants: "Hydrogen-rich Blast Furnace"

Using hydrogen as a fuel and reducing agent in iron smelting, hydrogen

metallurgy reduces CO2 emissions. The "hydrogen-rich blast furnace" is a

leading technology for green and low-carbon steel production.

(4) Opening the "Black Box of Blast Furnaces": Hydrogen-rich Blast Furnac

e Digital Twin System

(a)"Blast Furnace Thermodynamic Calculation Software" can calculate the

thermodynamic equilibrium conditions of various furnace locations in real

-time based on the data obtained from blast furnace monitoring. By iterat

ively solving the complex thermodynamic equilibrium relationship betwee

n gas concentration, temperature, and pressure, it translates the thermod

ynamic conditions into "real blast furnace operating conditions," which is

the key technology to open the blast furnace black box; (b) "Visualized Re

duction Kinetics Model" takes the obtained "real blast furnace operating c

onditions" as input and utilizes reaction kinetics models to predict the co

mplex reaction behavior of iron ore within the blast furnace, achieving hy

drogen-enriched blast furnace digital twinning technology with real-time

predictive capabi

Due to NCKU’s rapid development, the R&D Committee has become increasingly important. In order to meet the needs of NCKU's academic research planning, integration, industry cooperation and academic cooperation, it has become an independent operating unit for practical functions. Therefore, in the 5th University Council of the 1994 academic year, the R&D Committee was renamed the Office Of R&D(ORD) after the amendment of Article 8 of NCKU’s organizational regulations. NCKU Regulations Governing the Establishment of the Office of Research and Development were approved in the 7th University Council of the same academic year. In addition to the original three divisions, the instrumentation equipment center was established for integration and planning of NCKU’s relevant instrumentation and equipment, bringing further into play the overall function of ORD, which will be more beneficial to NCKU’s teachers and students. In June 2006, the Office of International Academic was established. The Academic Cooperation Division of ORD Department was converted into the International Cooperation Division and shifted to the Office of International Academic. Original URL: History and Vision https://en.ord.ncku.edu.tw/article-history.html The copyright belongs to the author. For commercial reprints, please contact the author for authorization, and for non-commercial reprints, please indicate the source.

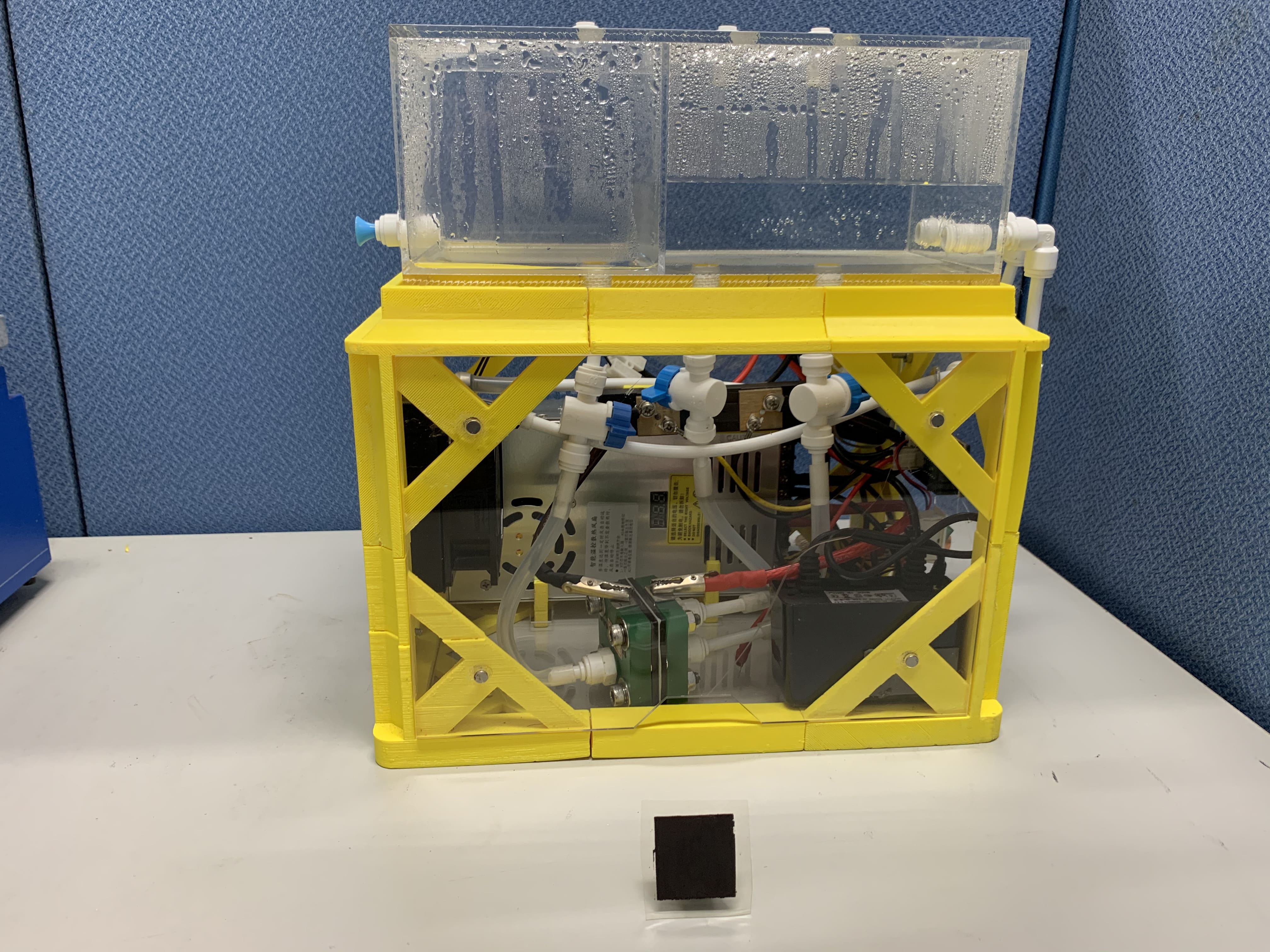

Renewable hydrogen economy- R&D of electrolysis energy storage and application of green hydrogen industry-academia consortium project

Green adsorption materials and energy-saving exhaust gas treatment equipment used in the treatment of industrial volatile organic compounds

Solvent recycling (solvent collection) system; CLEAN-ACE800 series Continuous Vacuum Distillation Recovery System

Development of a New Generation of Hydrogen Storage Tanks - Ultra-Thin Thermoplastic Winding Tape Process Technology

Technology maturity:Experiment stage

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!