This technology can combine additive design of dissimilar metals through friction stir welding, and form various 3D structural dissimilar aluminum alloy parts through additive manufacturing method of solid state process. This technology can maintain the characteristics of the raw materials and complement the characteristics of dissimilar metals.

MIRDC (Metal Industries Research and Development Centre) continues to assist in industrial upgrading and transformation in response to policy development and the trend of the times, with five major industries, including metal material & fabricated metal products industries, high value-added precision micro manufacturing, green energy, high value equipment and medical devices & healthcare, as the core development, proactively promotes technical innovation and high-value applications. The Centre has not only strengthened the link between domestic and foreign technology R&D and the integration of talent and resources, but also established a cross-discipline R&D ecosystem. MIRDC has become a globally recognized R&D institute focusing on value-added activities for metal related industries.

Name:

Phone:07-3513121#2365

Address:No. 1001 Gaonan Road, Nanxun District, Kaohsiung City

Key Technology for Advanced Industry 4.0: Advanced Intelligent Manufacturing Cell, 3D Printing Design Systems, AI Expert System for Friction Stir Welding Process

NCU-Covestro Research Center: Research and Development of Green Advanced Functional Materials and Manufacturing Processes

.png)

Green & Continuous Manufacturing, a novel integrated liquid-liquid micro-extractor and separator for rapid downstream process characterization.

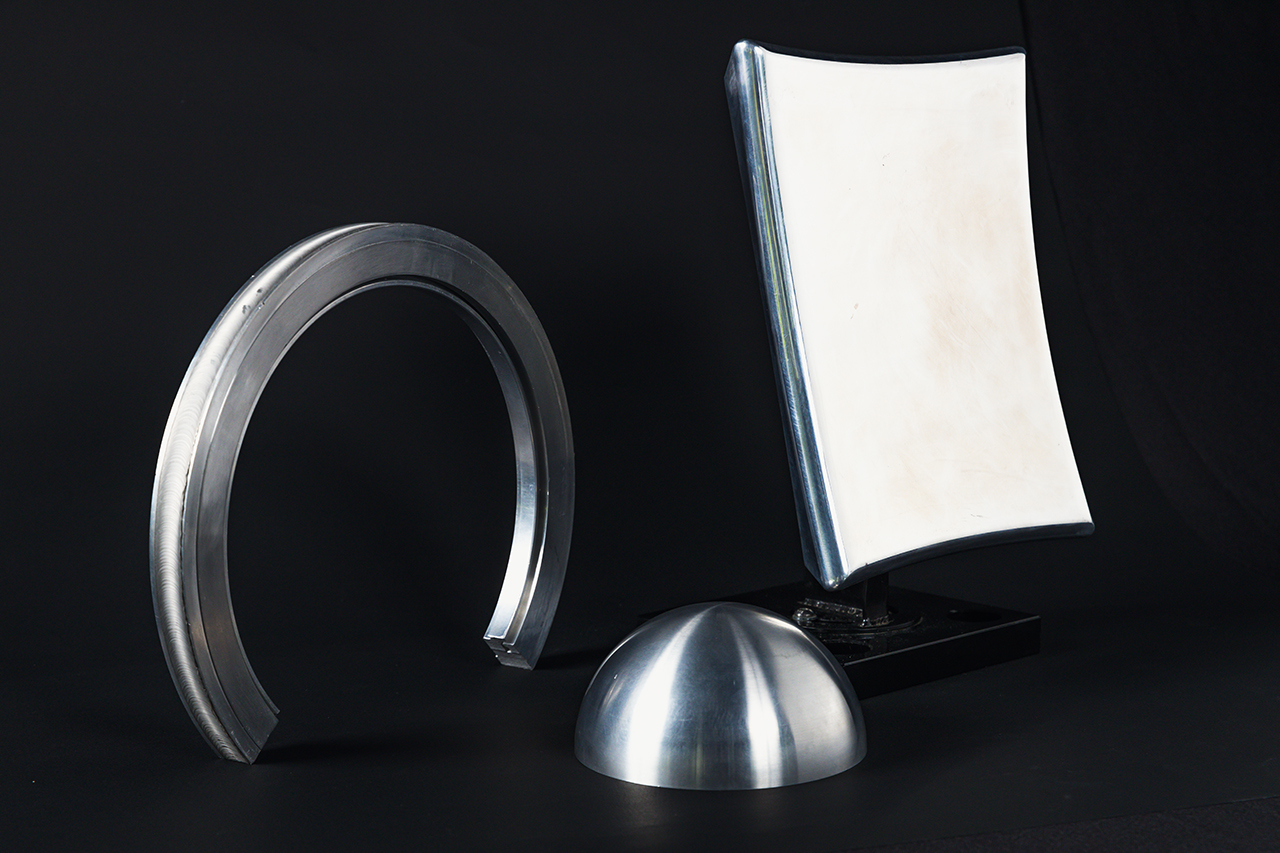

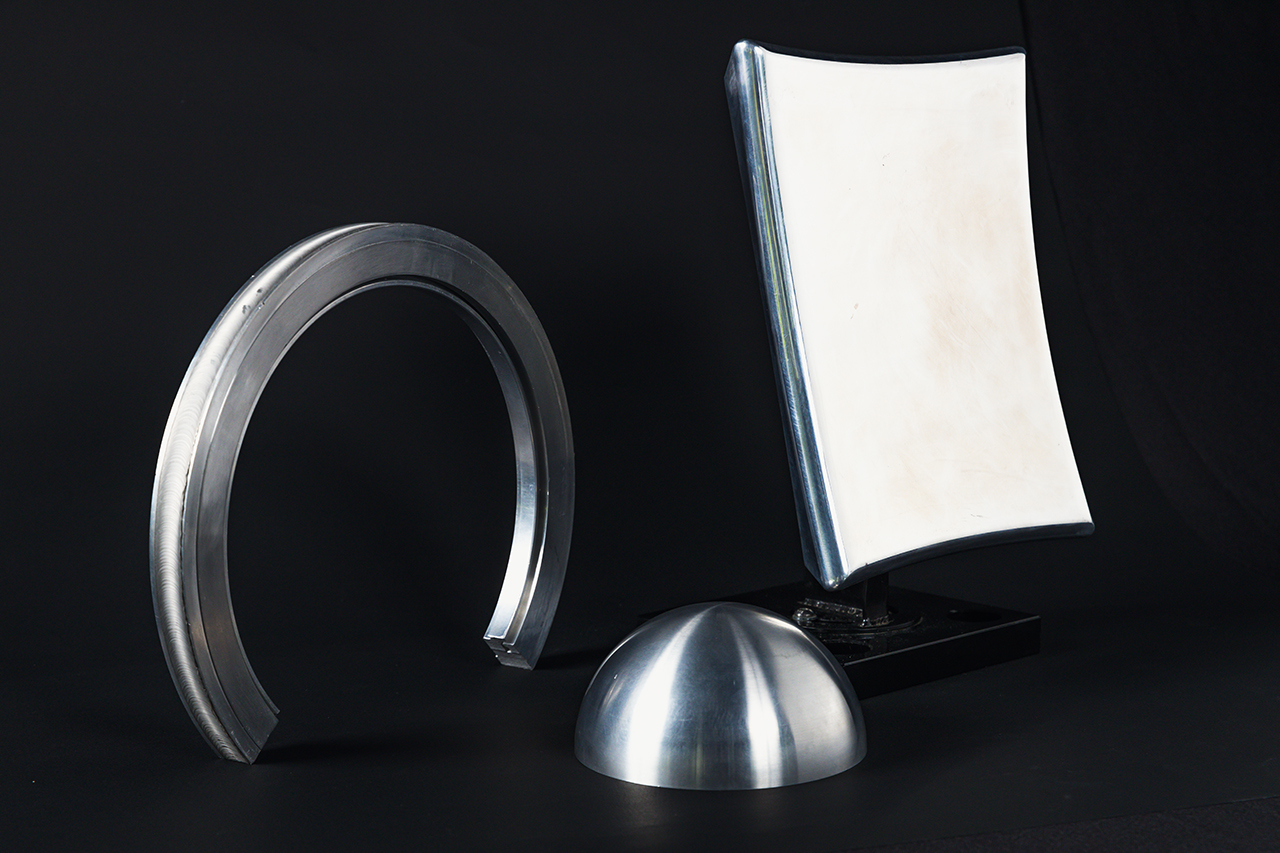

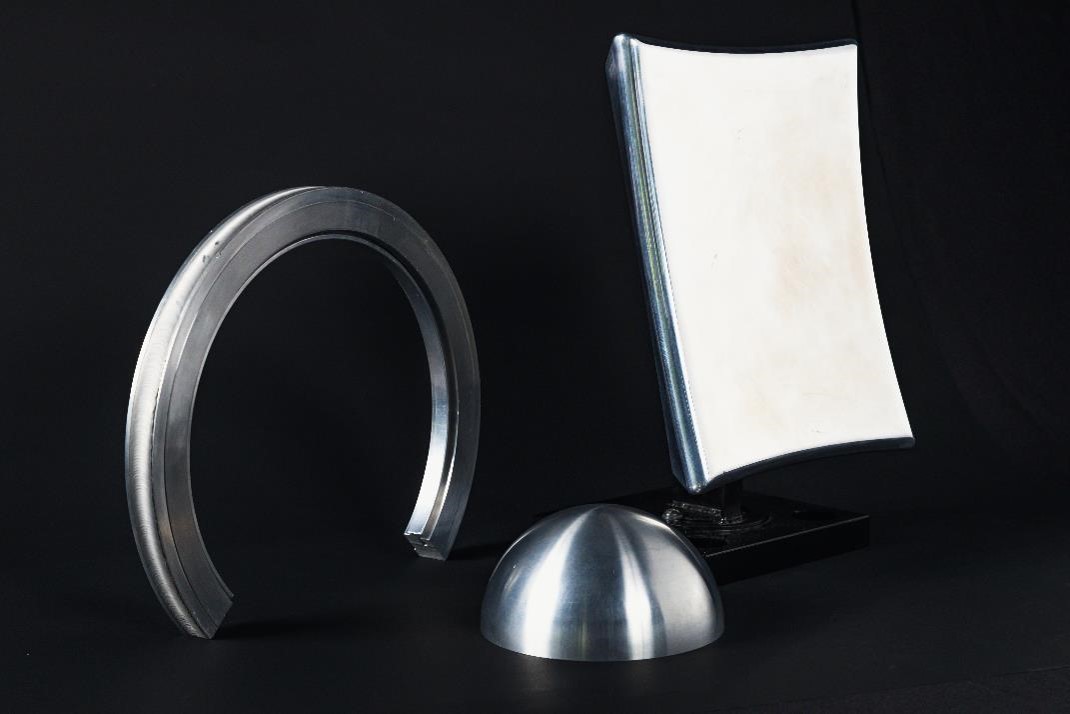

4D (3D+Dissimilar) Printed of Solid State Process

Technology maturity:Trial production

Exhibiting purpose:Display of scientific results、Technology transactions

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!