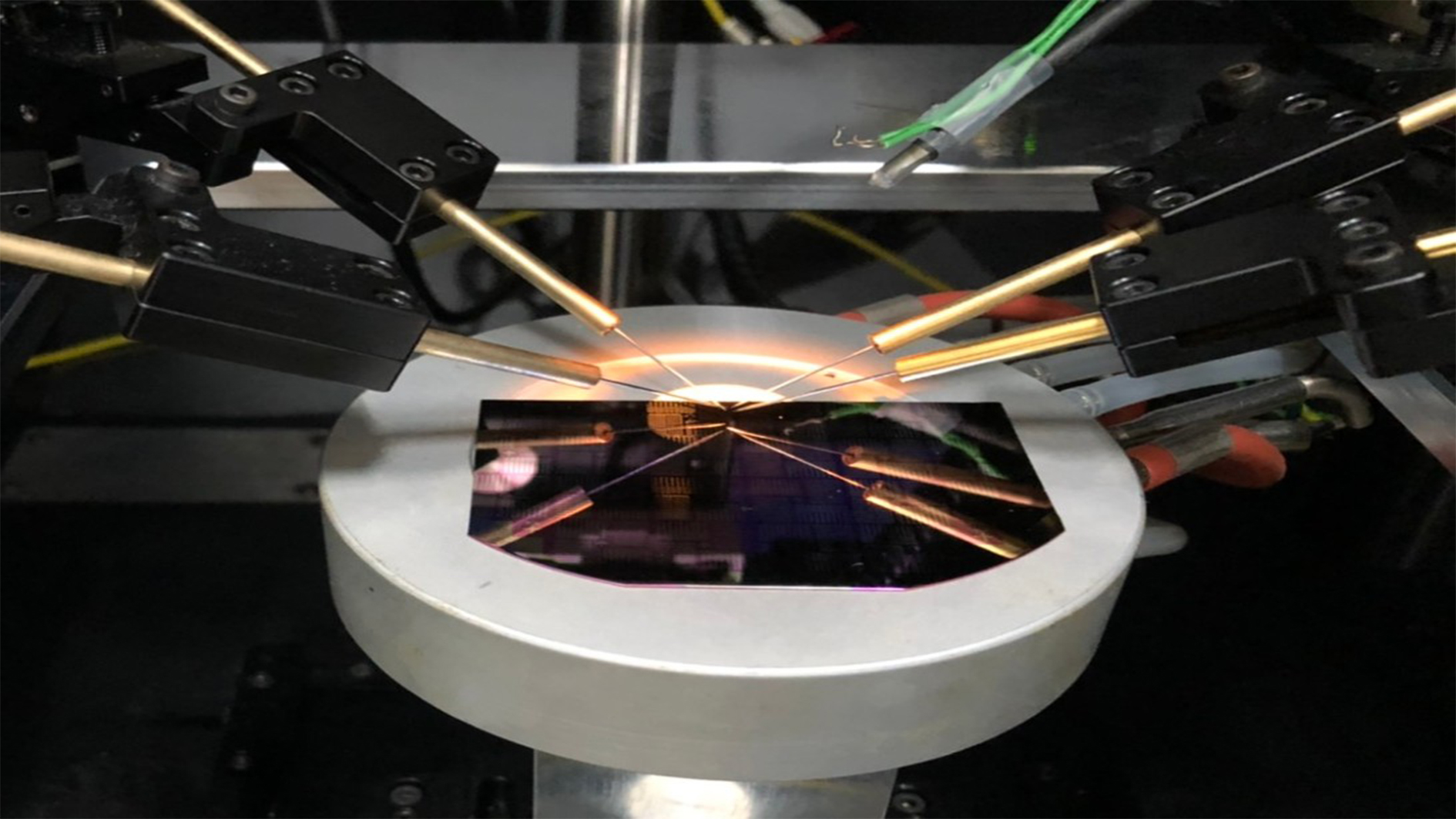

Fast Beam CalibrationForming for Phased Arras of Antennas at Millimeter Wave Frequencies for 5G/B5G Applications

Active phased arrays of antennas suffer from fabrication discrepancy at mmW frequencies for 5G/B5G. To accelerate the piece-by-piece calibration procedure, a bottleneck to cause high fabrication cost, a highly efficient electronic-scan based technique is developed. By avoiding the time-consuming mechanical probing, the developed technique is particularly applicable to production line operation to enhance production yield rate. It allows the system architecture significantly simplified while its calibration efficiency is tenfold better than conventional technique, a tremendous reduction from hours to seconds. Its applications not only enhance system performance, but also significantly reduces mass-production cost for effective commercialization of 5G services at mmW frequencies.This technology utilizes active RF devices to calibrate the array antenna beams, which breaks through traditional iterative mechanical architecture scanning. This electronic-scan based technology can achieve unidirectional beam correction, implement a space reduction of 70%, and reduce the calibration time from "hours" to "seconds" Level (less than 1% of conventional mechanical scan technique), system cost reduced by 60%. In addition, this adjustment can simplify the layout of the beamforming circuit to reduce losses and improve characteristics. Its implantation into the production line system, may reduce significantly the system production cost. In particular, its “second”-level calibration speed can improve yield, significantly reduce production line costs, and increase production speed.The proposed technique can be applied in various scenarios at mmW frequencies. It may simplify antenna system architecture for low power consumption at R&D stage, and reduce development efforts for various RF components. At production stage, it can be applied to production lines for space-saving, cost reduction and good yield rate enhancement. Combining with existing production automation flow using robots, the high calibration efficiency also accelerates the system production in tenfold efficiency comparison to mechanical-probe based techniques. Production speed and cost saving can be assured. This technique has high applicable scenarios, and can be extended for field system to pair with user equipment, performing fast beam forming and tracking for easy use of commercial systems.

Name:林思華

Phone:02-3366-1893

Address:No. 1, Sec. 4, Roosevelt Rd., Taipei 10617, Taiwan (R.O.C.)

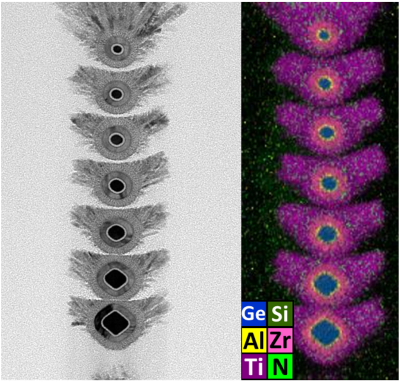

High mobility materials, process, stacked channels, and thermal circuit simulation; Ferroelectric X:HfO2 for Negative Capacitance and POC(Proof-of-Concept) Applications; Atomic layer technologies for

.png)

Smart measurement system for advanced PCB with high speed and high frequency requirements Innovative technology for HPC 5G and High Power Filed

Packaging of Electrically Large Phase Array of Antennas at Millimeter Wave Frequencies for 5G/B5G Applcations

Low Temperature Polycrystalline Silicon Oxide (LTPO) TFT Architecture with Memory-embedded in Pixel for High-resolution and Power-saving Near-eye VR/AR Displays Applications

Technology maturity:Prototype

Exhibiting purpose:Technology transactions、Product promotion、Display of scientific results

Trading preferences:Technical license/cooperation、Negotiate by self

Coming soon!