UV-resistant Self-healing Emulsion Glass as a New Liquid-like Solid Material for 3D Printing

Directly writing 3D structures into supporting mediums is a relatively new developing technology in additive manufacturing. In this work, durable and recyclable liquid-like solid (LLS) materials are developed as supporting mediums that are stable for both UV- and thermal-solidification. Its elastic nature emerges from the jammed structure of oil droplets, ffers this LLS material rapidly self-healing ability. The capability of the emulsion glass as supporting mediums is successfully demonstrated by directly writing and then curing designed structures. The emulsion glass has been repeatedly used at least 6 times upon exposure to UV irradiation and heat, implying it can expand the applications of supporting medium to the writing process involving UV- and thermal-curable inks simultaneously.Directly writing 3D structures into supporting mediums is a relatively new developing technology. The dilute dispersion of Carbopol in the aqueous solution has been the most frequently used materials for supporting mediums in which to write 3D structures. However, photo- and thermal- degradation of Carbopol may be inevitable during the solidification of ink material, limits the usage of a polymer-based supporting medium. Our proposed supporting medium possesses the self-healing ability and tunable yield stress. Because the components of this emulsion glass are mostly water and oil, it exhibits chemical stability when exposed to UV radiation and high temperature. Based on the above features, this emulsion glass can be regarded as a new kind of LLS material for supporting mediums.Embedded 3D printing is a recently emerging technology. This technology has been utilized to create various complex 3D architectures, which would be difficult to make solely by typical 3D printing methods. For example, supporting mediums have been applied to 3D-photopolymerization and the production of PDMS elastomer and liquid metal. After writing, the whole system including written inks and supporting medium is exposed to UV or high temperature for a while to obtain a solid structure. If the medium is degraded before solidification, the written structure will sag or fall apart due to the failure of the elastic solid-like support. To prevent the occurrence of this scenario, the LLS material must exhibit good thermal and UV stabilities.

Name:因敏綸

Phone:03-4227151#34226

Address:No. 300, Zhongda Rd., Zhongli District, Taoyuan City

Nano-Dimensional Self-Healing Technique and The Development for Elastic and Self-Healing Polymer Semiconductor

NCU-Covestro Research Center: Research and Development of Green Advanced Functional Materials and Manufacturing Processes

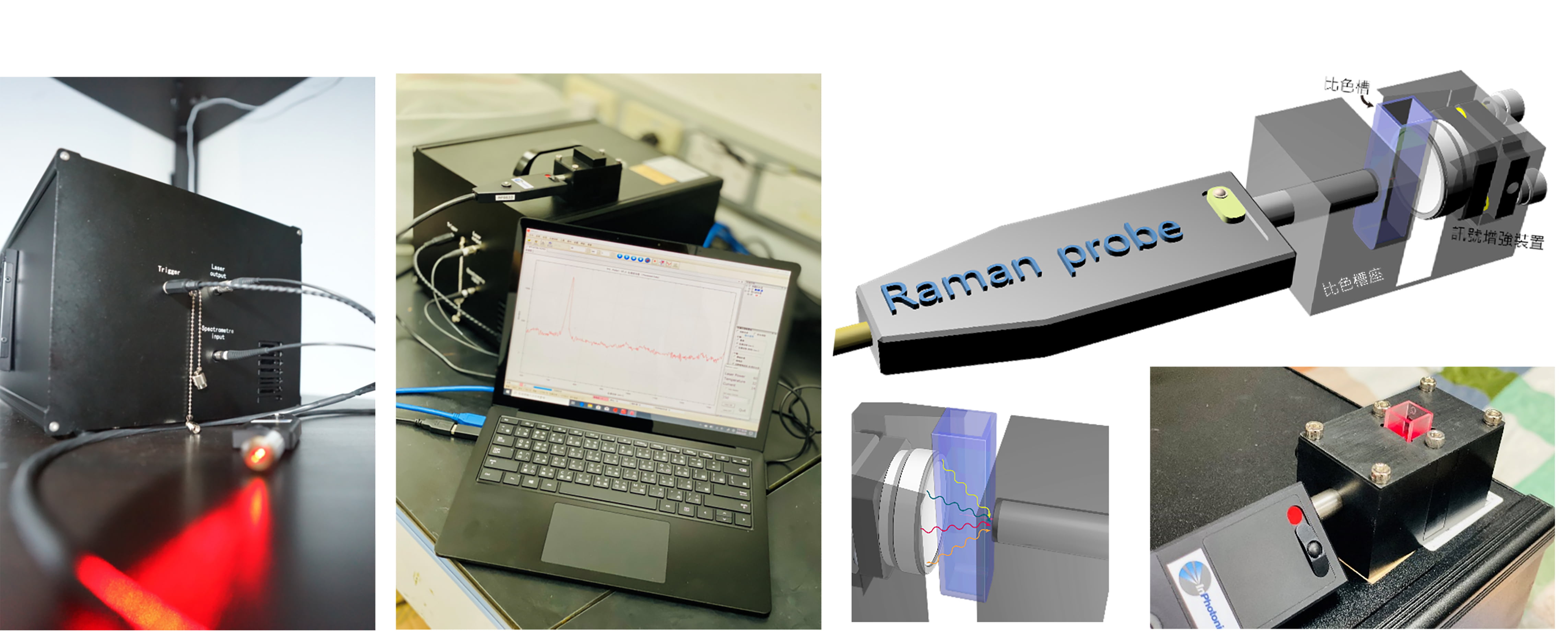

Magnetic and 2D metallic Nanoparticle Arrays of Surface-Enhanced Raman Spectroscopy (SERS) Detection Platform for Environmental-Biomedical Sensing

.png)

Green & Continuous Manufacturing, a novel integrated liquid-liquid micro-extractor and separator for rapid downstream process characterization.

Technology maturity:Experiment stage

Exhibiting purpose:Technology transactions、Product promotion、Display of scientific results

Trading preferences:Technical license/cooperation

Coming soon!