A microscale conductance that can satisfy the condition of molecular flow up to atmospheric pressure.

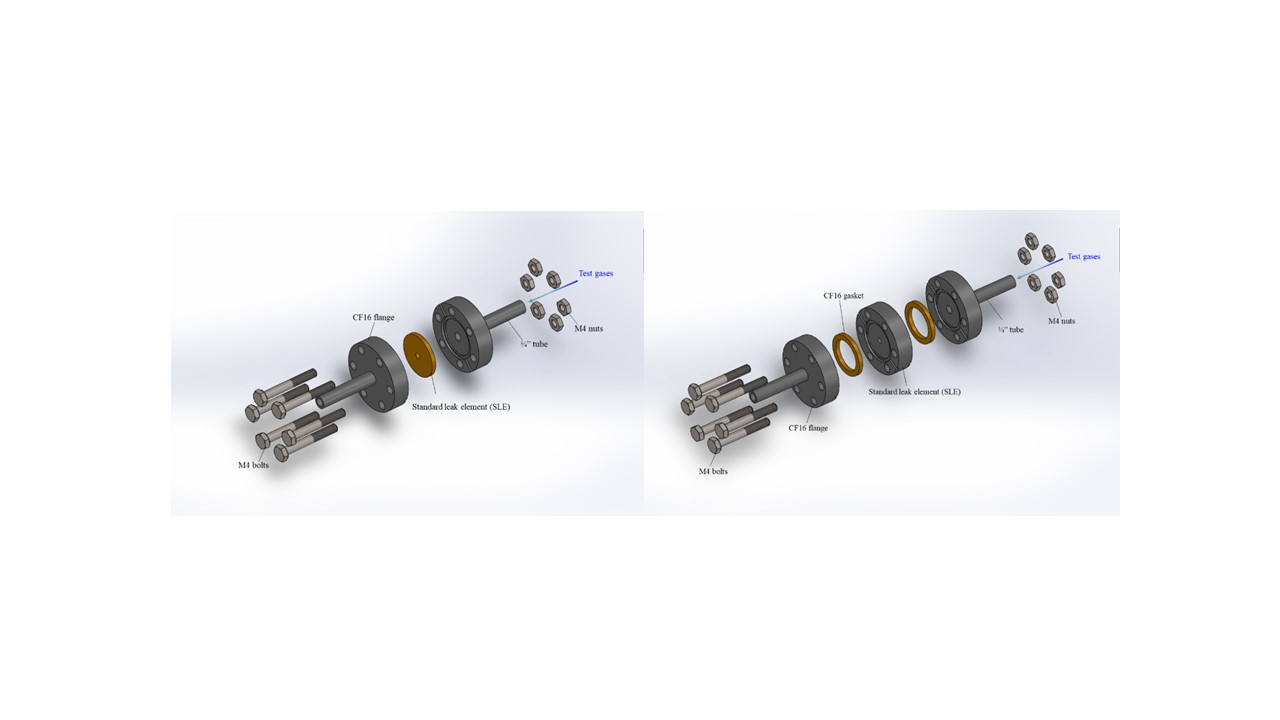

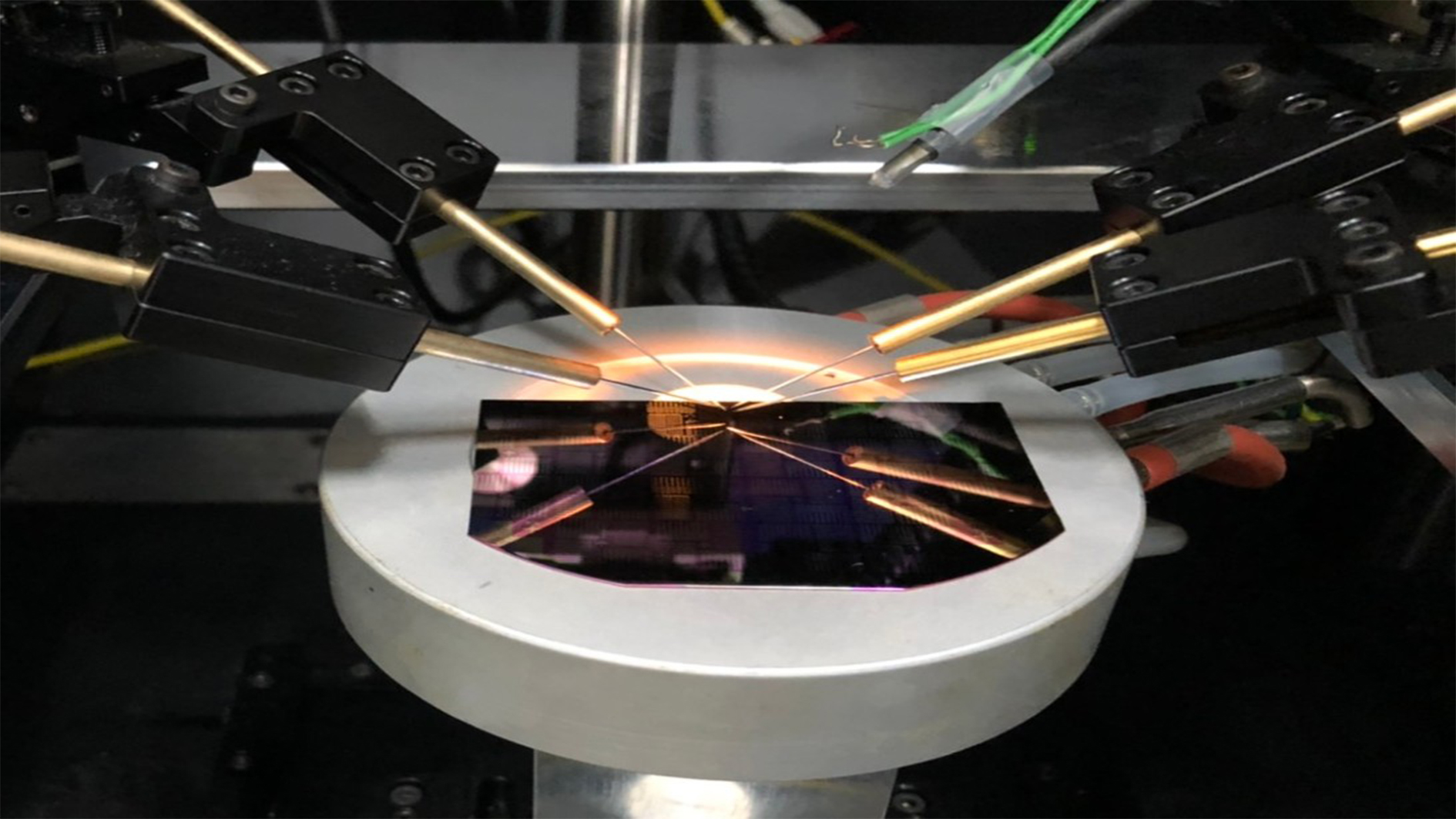

Two new kinds of the standard leak elements (SLEs), with a microfluidic channel in diameter of several-micrometers and length of several-hundred-micrometers, have been developed by femtosecond (fs) laser micromachining. A technique based on the conductance modulation method can be used to accurately determine the tiny conductance (< 1×10-6 L s-1) of these SLEs.

Most leak paths of the SLEs in the literature (e.g., Nano hole, multichannel, AAO) were fabricated in a non-metallic substrate; a subsequent sealing process was hence required to attach these non-metallic leak elements to flanges for vacuum applications. Torr Seal® is the most commonly used sealant for vacuum sealing, but its outgassing rate is of order 10-7 mbar L s-1 cm-2 and a baking temperature must not exceed 120 0C. We propose a simple approach using fs laser micromachining to make the SLEs, which can be compatible with an UHV environment and can withstand higher baking temperatures.

This invention can serve to (a) calibrate the sensitivity of an ionization gauge and residual gas analyzer (RGA) for various gases, (b) calibrate the leak rate of a helium leak detector, (c) measure the pumping speed and the sorption capacity of a vacuum pump, (d) supply a precise and constant gas flow in cooperation with a low-vacuum gauge (e.g., capacitance diaphragm gauge, CDG), and (e) be a tiny differential pumping element, between which a desired pressure gradient can be attained with an appropriate pumping speed.

線上展網址:

https://tievirtual.twtm.com.tw/iframe/58e76bf8-b925-456a-80ee-b7b350744dda?group=23bfb1fa-dd5b-4836-81a1-4a1809b1bae5&lang=en

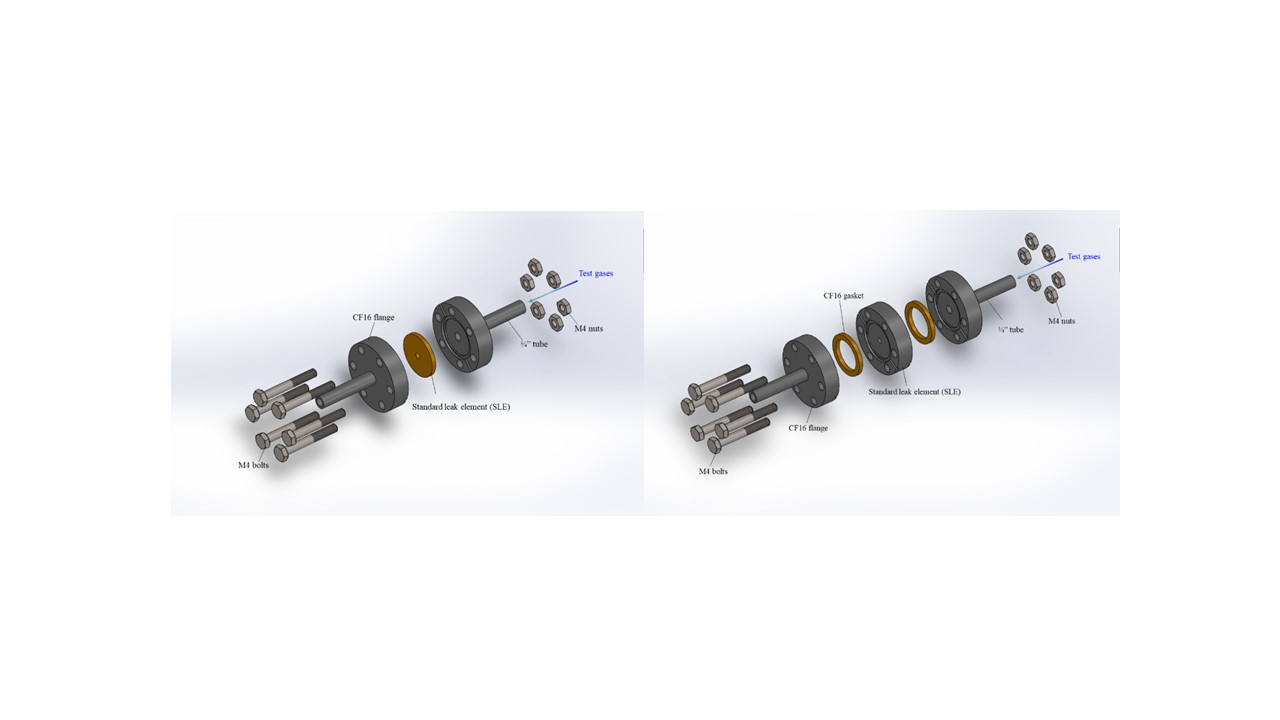

Remote-control robot agent for epidemic prevention robot using the combination of virtual reality and inertial measurement unit based posture detector

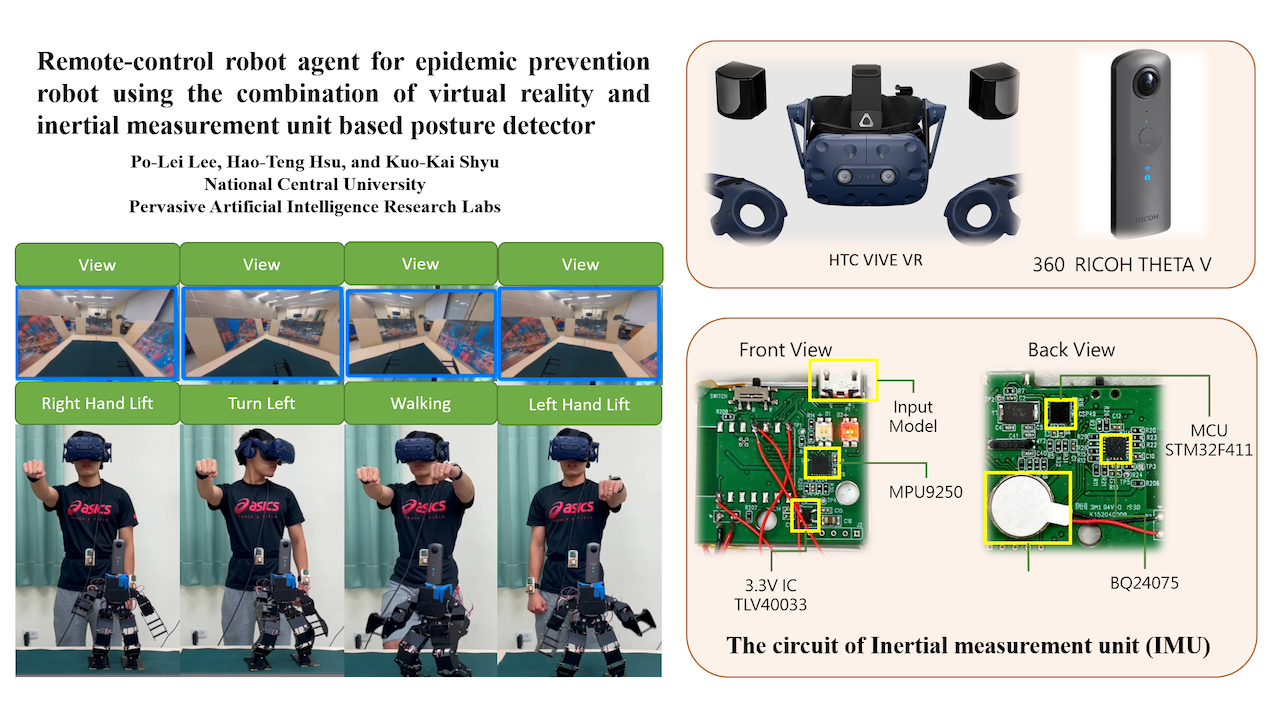

Antenna-in-package (AiP) Technology Suitable for Feeding to the Smart Impedance Material for High-Gain Radiations at Millimeter Wave Frequencies

Low Temperature Polycrystalline Silicon Oxide (LTPO) TFT Architecture with Memory-embedded in Pixel for High-resolution and Power-saving Near-eye VR/AR Displays Applications

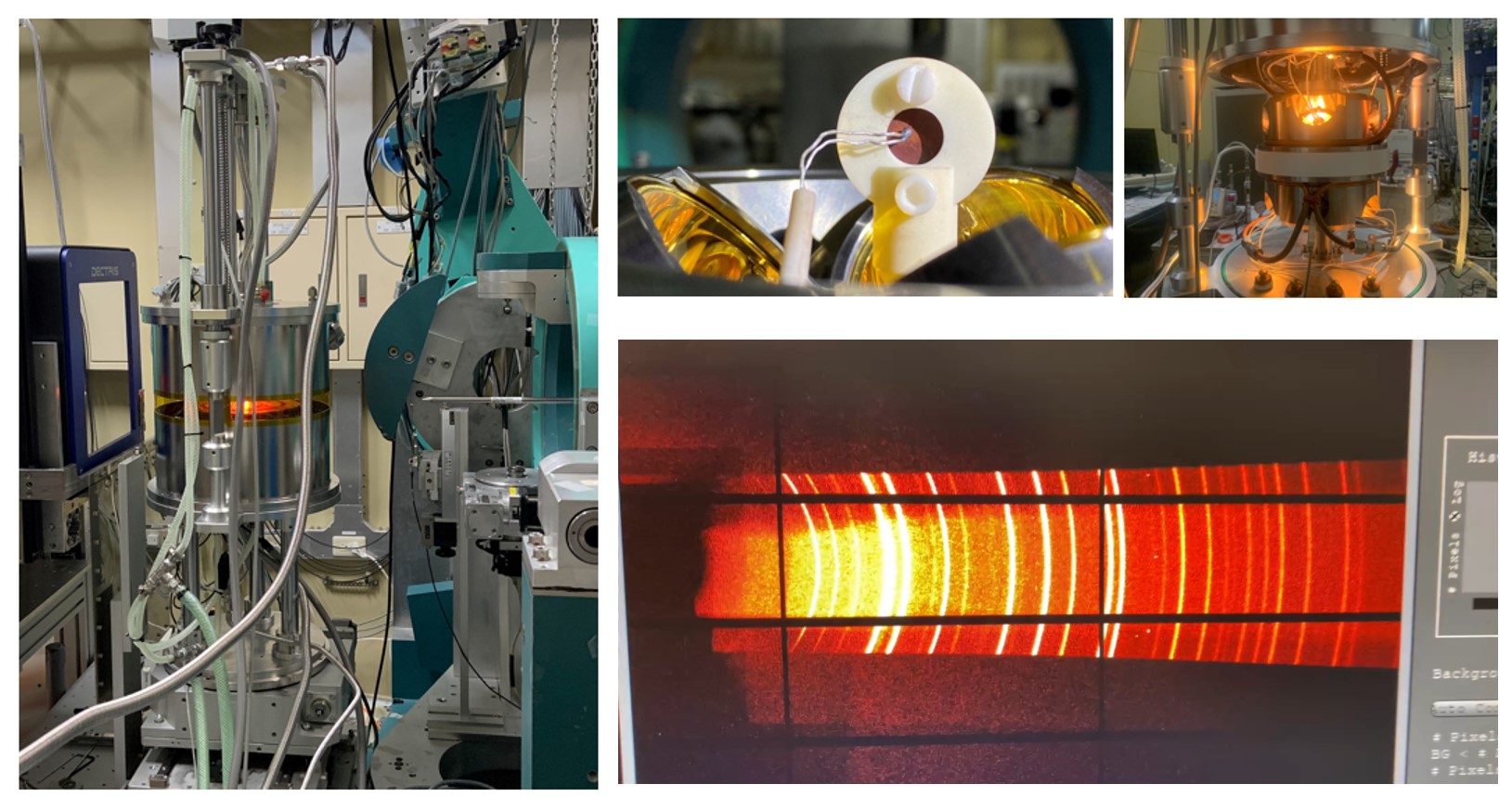

Refining area at 1600°C: Advanced synchrotron X-ray views into the black box of blast furnaces, understands ironmaking process, and illuminates the bright road to net-zero carbon emissions

Technology maturity:Trial production

Exhibiting purpose:Product promotion、Display of scientific results

Trading preferences:Negotiate by self

Coming soon!