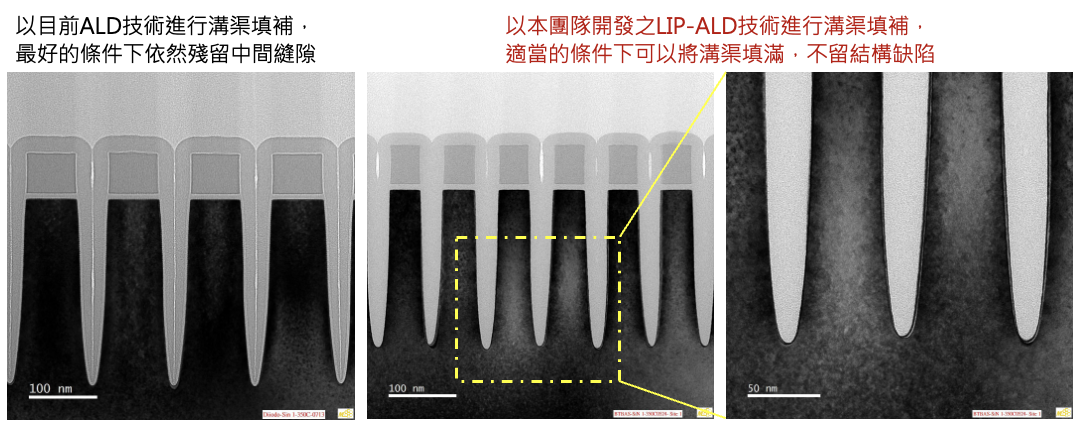

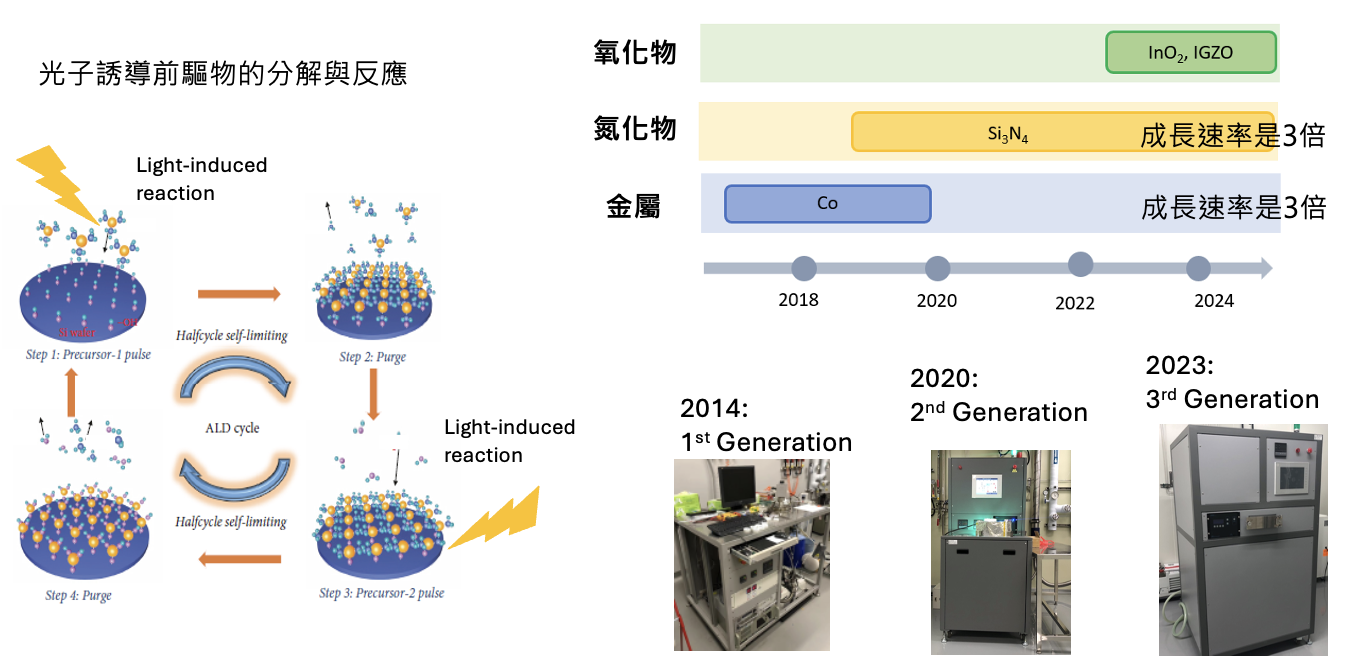

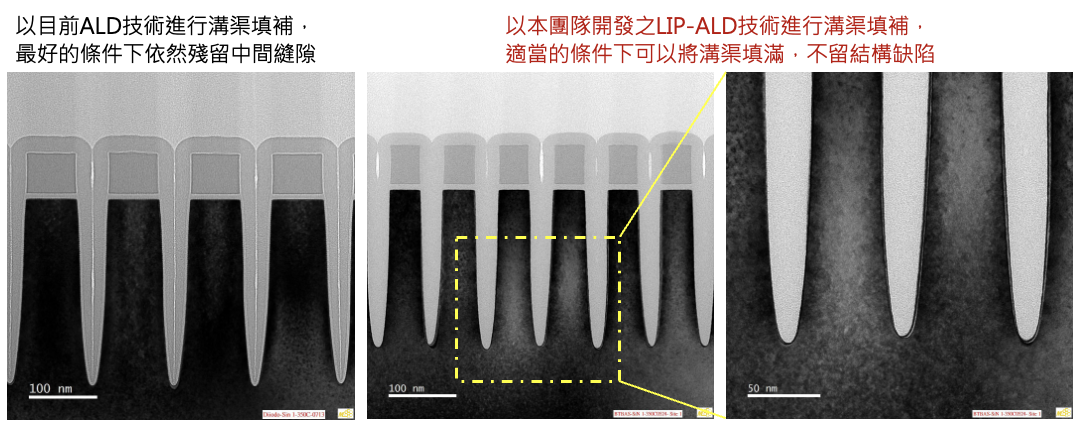

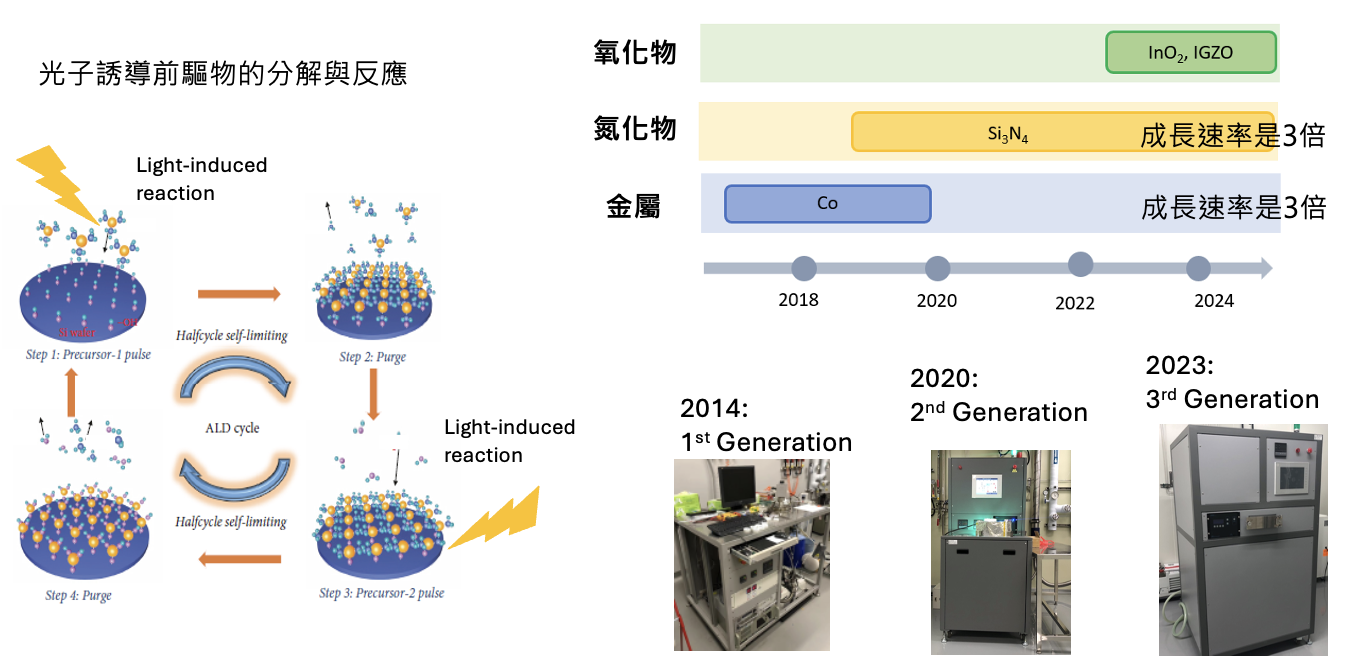

Existing ALD techniques fail to address the issues of residual voids and seam defects in trench filling. We have developed a photo-induced precise ALD (LIP-ALD) technique over the past decade, which enables precise control of atomic deposition for gap fills. It has achieved seamless, pore-free, and low-impurity dielectric material deposition in high aspect ratio N3 and N2 node structural wafers. AMAT, AL, and TSMC have co-joined the research of this novel LIP-ALD process in NTHU with our team.

The Intelligent Cloud Platform for the Machinery Industry and on-premise Taiwan Machinery Standard Runtime networking technologies.

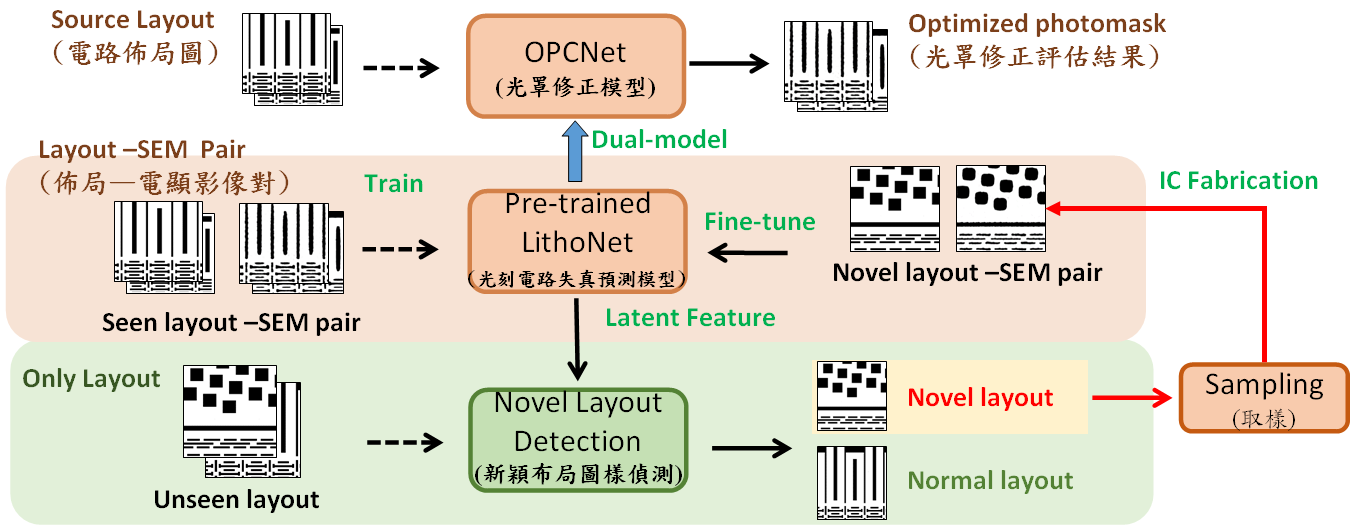

Deep learning-based EDA tools for lithography simulation, photomask correction, and novel layout patterns detection

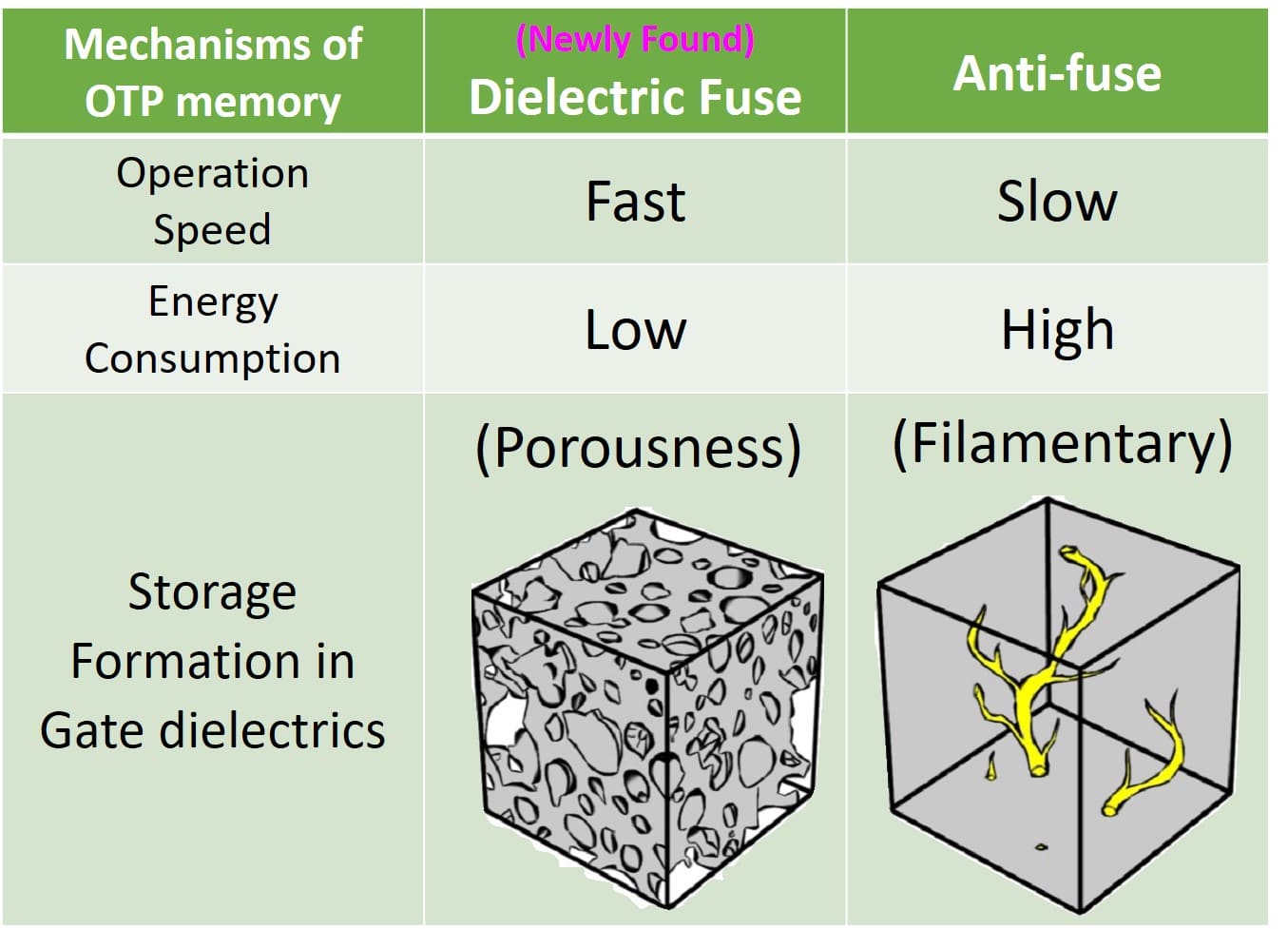

A Low-cost, Low-power, and High-speed “Dielectric-fuse Breakdown OTP” (dFuse OTP) Fully Integrated on CMOS Platform without Additional Masks

Low Temperature Atomic Layer Deposition Technology with High Aspect Ratio Multi-component

Technology maturity:Prototype

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

Coming soon!