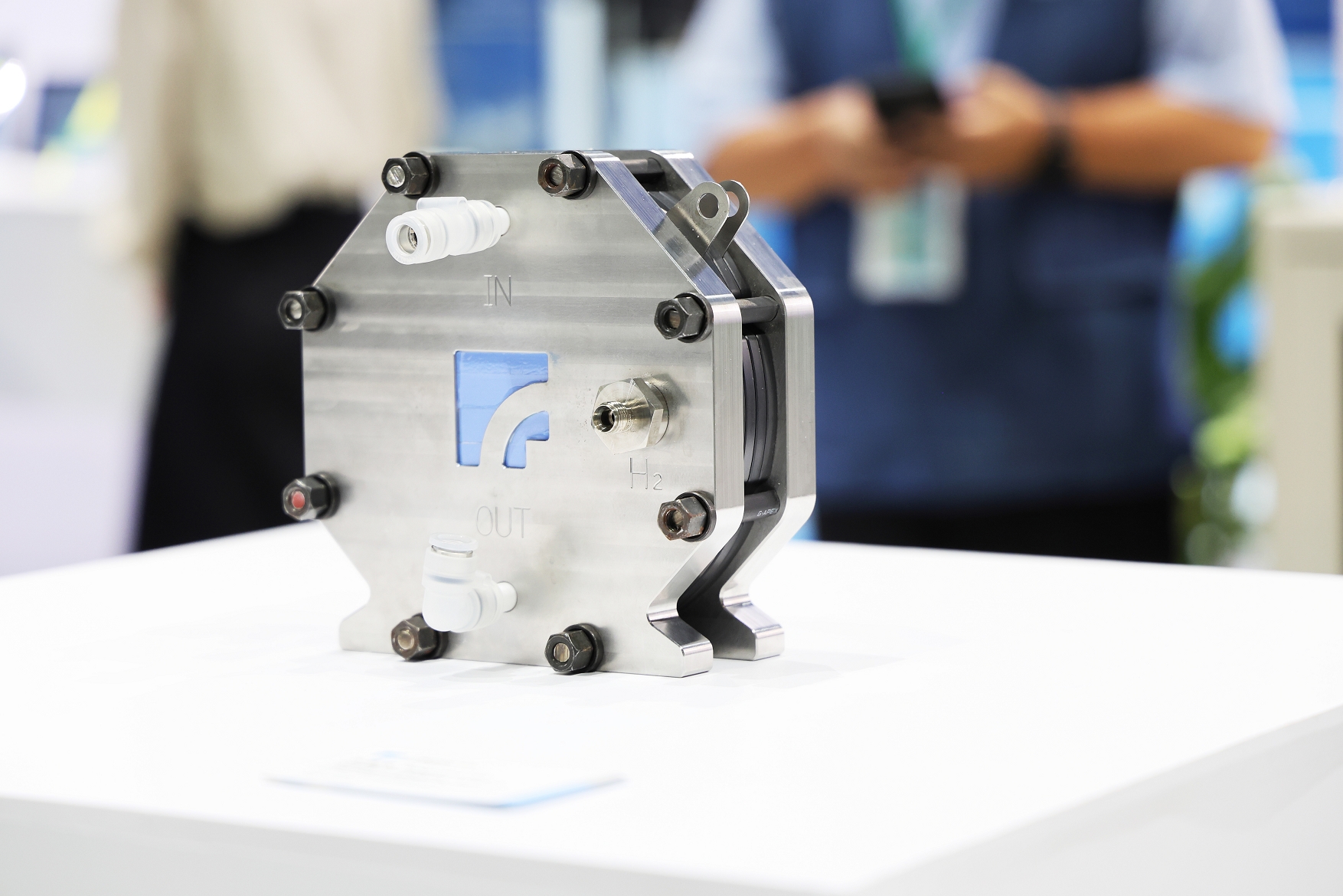

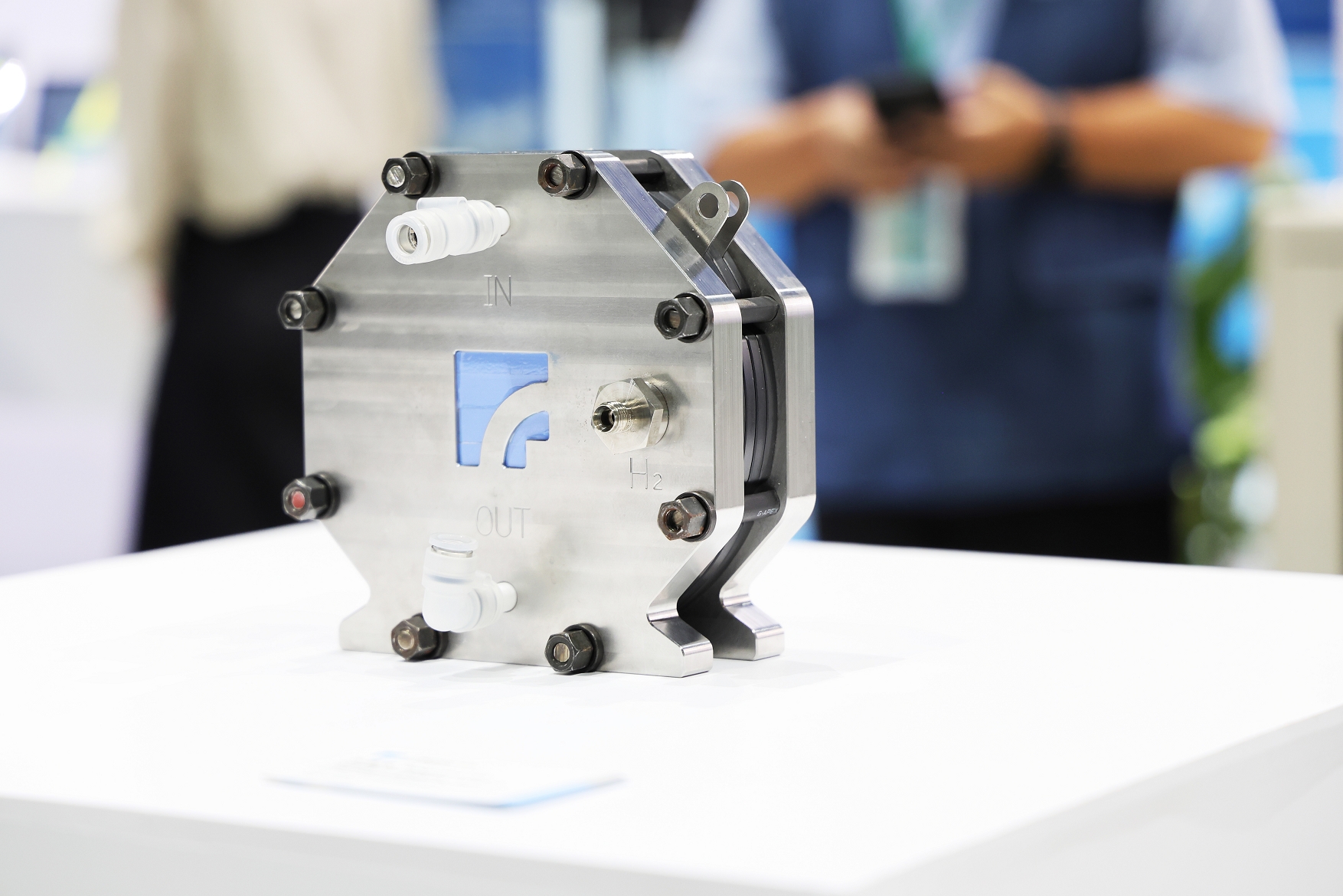

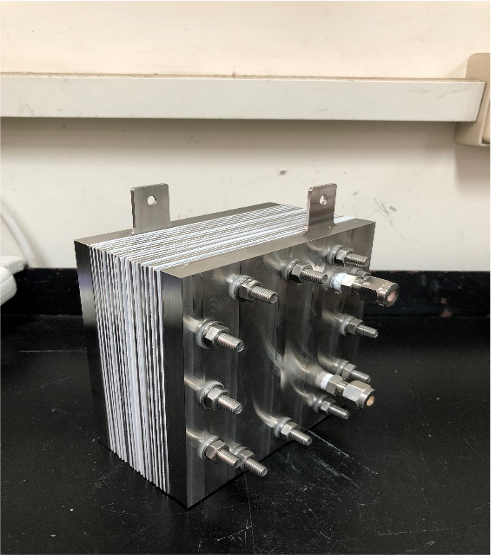

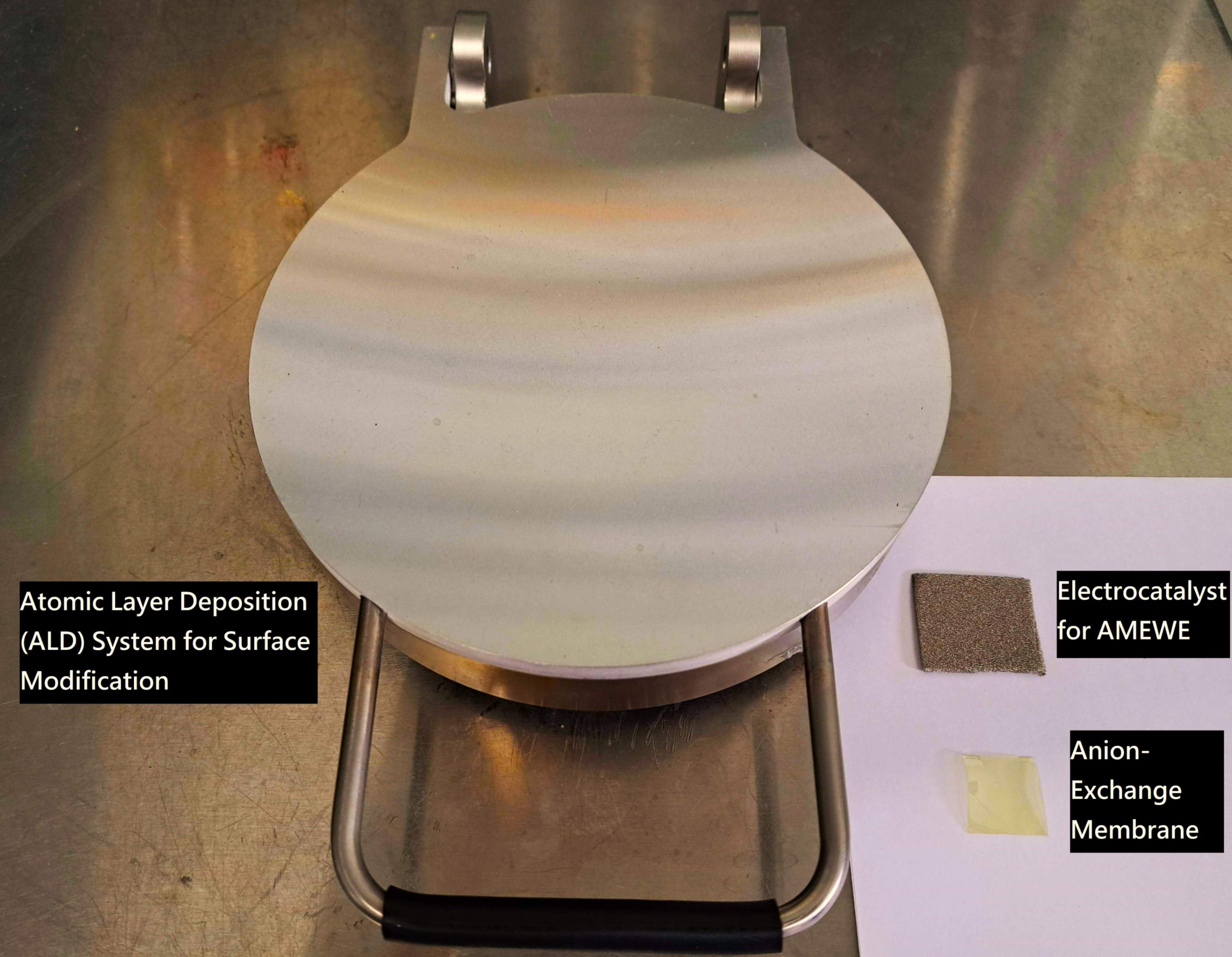

The hydrogen production efficiency of anion exchange membrane (AEM) high-pressure electrolyzers surpasses that of conventional alkaline electrolysis technology, and its material costs are more favorable than proton exchange membrane (PEM) technology. This technology offers advantages such as reduced usage of precious metals, high-pressure output, and adaptability to fluctuations in renewable energy. The hydrogen production efficiency of this technology can reach 65%, and it can operate at low alkaline concentrations (<1M KOH), providing operational and maintenance advantages. Additionally, the ability to directly generate hydrogen at 30 bar pressure reduces pipeline transportation costs or lowers the energy consumption for high-pressure storage on the back end.

High performance proton exchange membrane fuel cell based on laser processed alloy catalyst technique and metal foam flow field bipolar plate with built-in water-cooling design

Anion Exchange Membrane Electrolyser Stack For Hydrogen Production

High practicality surface modification technology for enhancing hydrogen production via water electrolysis and solid-state hydrogen storage efficiency

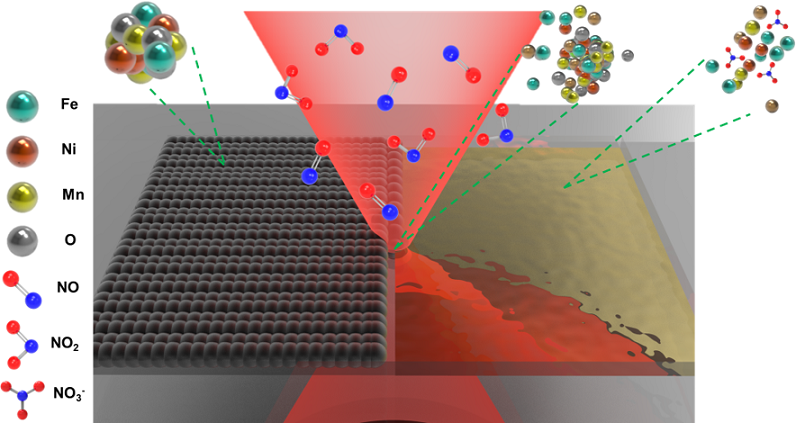

Porous Electrodes and Non-Precious Metal Catalysts: The Future of Anion Exchange Membrane Water Electrolysis Technology

Technology maturity:Experiment stage

Exhibiting purpose:Technology transactions、Patent transactions、Display of scientific results

Trading preferences:Exclusive license/assignment、Technical license/cooperation、Non-exclusive license

Coming soon!