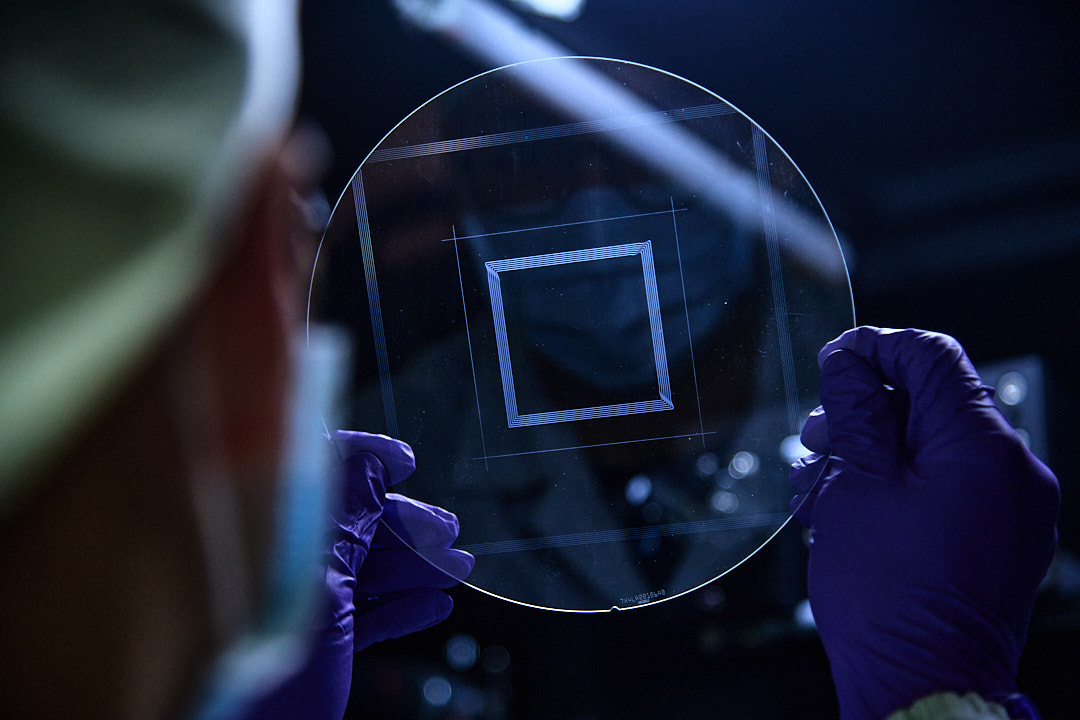

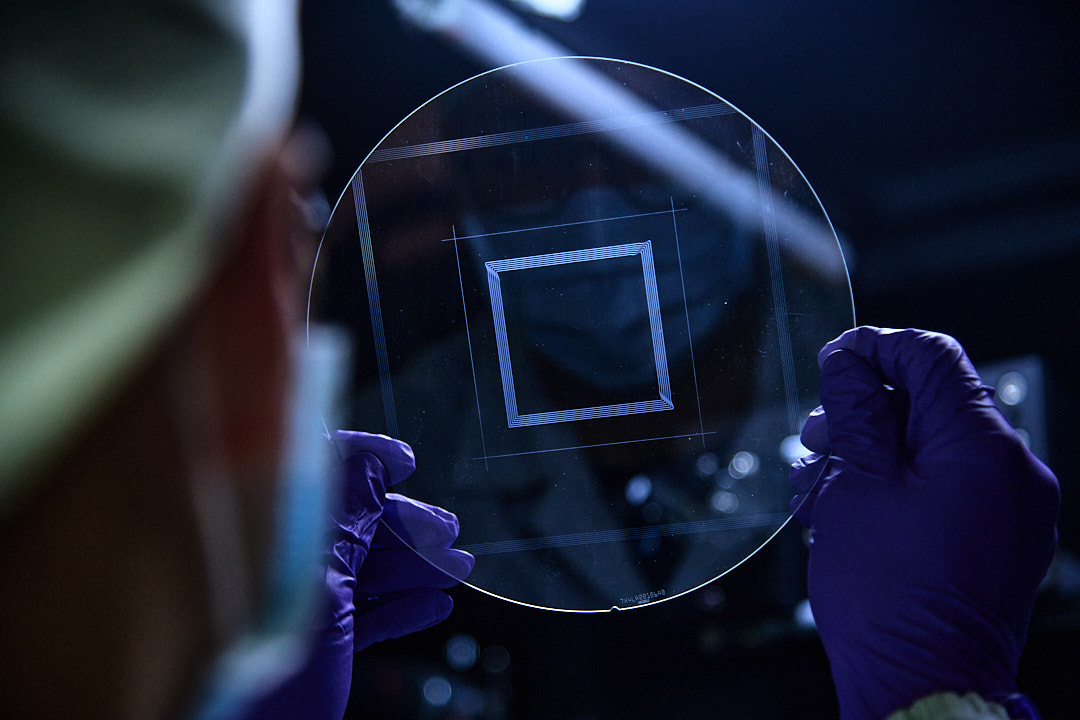

ITRI has developed advanced laser drilling technology for TGV interposers, integrating an ultrafast laser, a self-developed adjustable optics module, and a fluorine-free etching process. This enables substrate processing with aspect ratios up to 25, meeting high-density and high-I/O demands for 3D IC packaging. Compared to mechanical drilling, it boosts speed, reduces tool wear, and cuts carbon emissions by over 40%.

ITRI is a world-leading applied technology research institute with more than 6,000 outstanding employees. Its mission is to drive industrial development, create economic value, and enhance social well-being through technology R&D. Founded in 1973, it pioneered in IC development and started to nurture new tech ventures and deliver its R&D results to industries. ITRI has set up and incubated companies such as TSMC, UMC, Taiwan Mask Corp., Epistar Corp., Mirle Automation Corp., and Taiwan Biomaterial Co.

Name:Chien-Jung Huang

Phone:(06)6939-007

Address:No. 8, Gongyan Rd., Liujia Dist., Tainan City 734045, Taiwan (R.O.C.)

Enhancing Anodization of Semiconductor Materials Technology with Waf er Bonding Transforming Interface Function

The new material and application technology of weather-resistant and anti-corrosion solar photovoltaics frame in coastal field

Low Temperature Atomic Layer Deposition Technology with High Aspect Ratio Multi-component

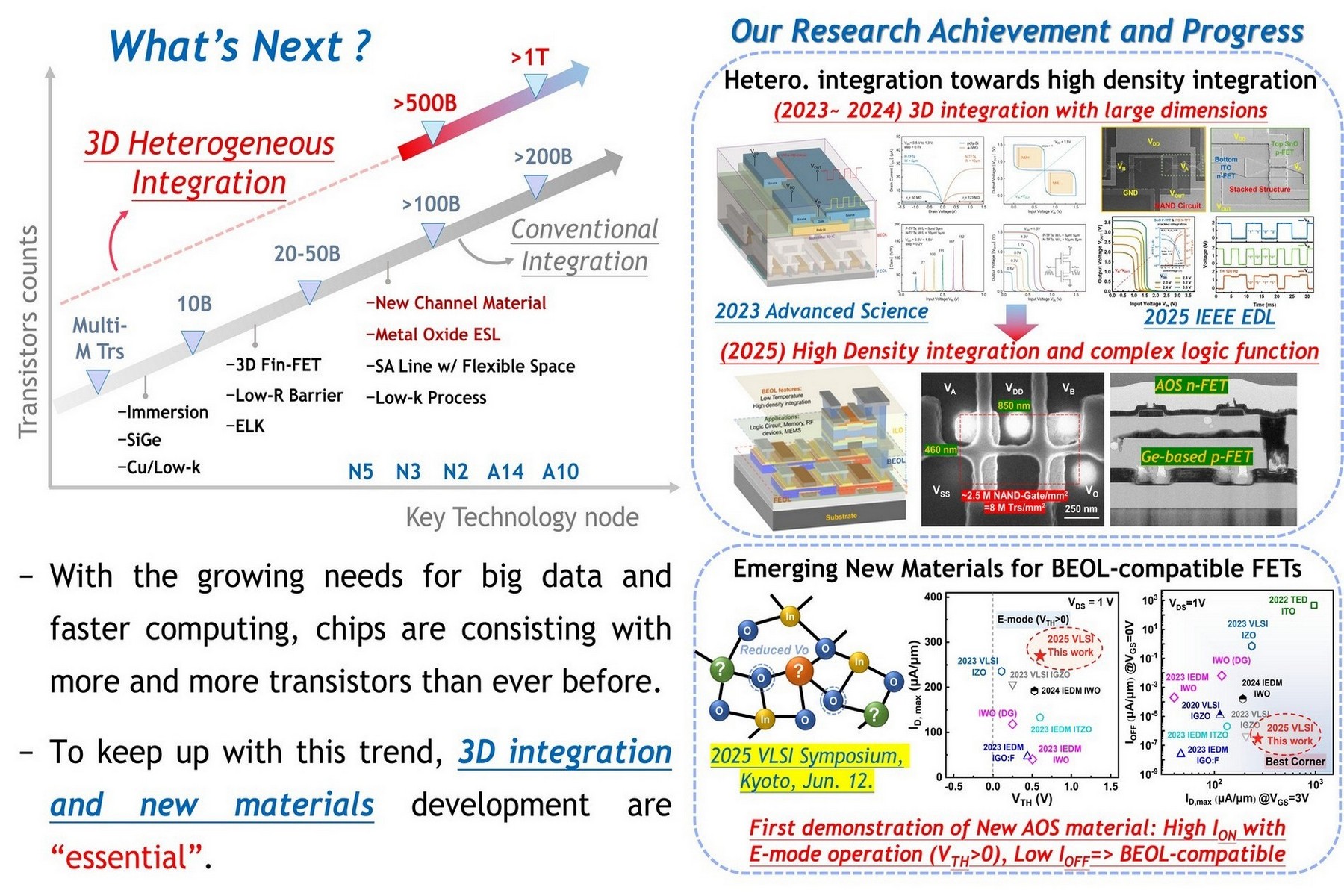

Monolithic 3D Heterogeneous Device Integration and Innovative Materials for Breaking Logic Density Limits: A Key Technology Platform for High-Density AI Computing Chips

Technology maturity:Others

Exhibiting purpose:Display of scientific results

Trading preferences:Negotiate by self

*Organization

*Name

*Phone

*Main Purpose

*Discuss Further

*Job Category

*Overall Rating

*Favorite Area

*Key Tech Focus

*Willing to Receive Updates?

Other Suggestions

Coming soon!